Mouse over to view evolution of toggle link assembly.

Home page

Article created: Wednesday, October 14, 2007

Home page

Article created: Wednesday, October 14, 20071898 Borchardt Luger 5 to 1900 old model production Toggle Link Assembly design evolution

The following is a summary of previously published material that covered a broad scope with some new additional information that focuses specifically on the design evolution of the Toggle Link Assembly from 1898-1899 through 1900 old model production.

The M1899 pre-production prototype Borchardt-Luger middle and rear toggle square link interface was introduced in 1898 on Borchardt-Lugers 5 and 6. It is basically identical to the toggle link on the 1893 C93 Borchardt pistol. Hugo Borchardt and initially Georg Luger considered the square link interface to be acceptable. That was soon to change.

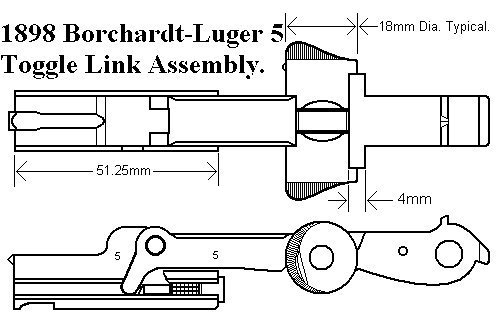

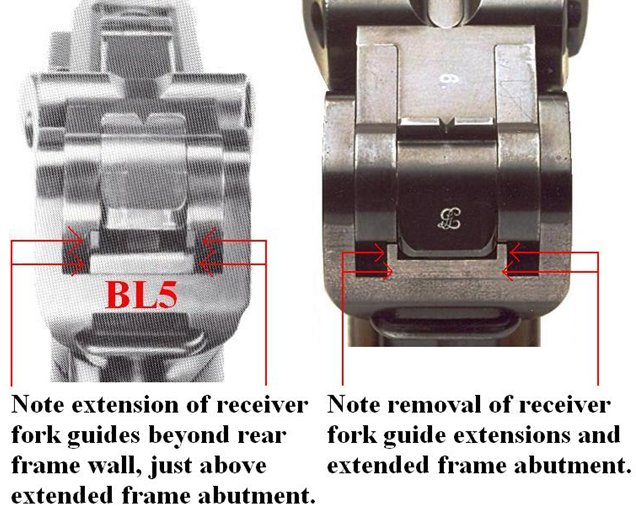

The pre-production and final design 1900 production Luger had a toggle link assembly with a radius middle and rear link interface, a 5 mm long toggle knob integral rear angle abutment and strengthened forward sloped integral rear link sight block. The pre-production 1899 replacement toggle link assembly had a 51.25 mm breechblock and the production breechblock length was 50.25 mm.

|

Old model toggle link assembly at maximum recoil

As with all Borchardt-Luger tolerances, the gap between the rear section of the breechblock and the forward coupling link surface at maximum dynamic recoil was extremely tight. This close tolerance condition is illustrated using the final M1900 production breechblock/coupling link configuration as an example. In maximum recoil the rearward movement of the breechblock can extend an additional 4mm beyond the static hold open position. This can be seen using a 1900 cut-way model showing the hold open static position and the maximum toggle link assembly recoil position with the coupling link disengaged. This extended maximum recoil position is where the underside of the rear link impacts the frame at the end of the firing cycle whereas the hold open static position allows the shooter to pull back on the toggle link, releasing the hold open from the breechblock allowing the assembly to return to the full battery position. The second mechanism in conjunction with the rear link underside/rear frame contact that restricts or halts the rearward movement of the breechblock is the forward left side position middle link integral tang that pulls back the firing pin until the tang engages a rearward slot edge of the breechblock at maximum recoil.

The gap was so close that the firing pin guide retainer head of the 51.25 mm in length breechblock was vertically slotted 5.5mm wide x 1.4mm deep to allow for additional clearance of the Riband recoil spring coupling link at maximum recoil. The firing pin guide slot was present on 1898 prototype Borchardt-Luger 5. When the rear frame abutment was eliminated with Borchardt-Luger 6 the rearward travel of the breechblock was further extended, albeit less than 0.5mm which made the clearance even more critical, yet not apparently enough to shorten the rear section of the original 51.25mm breechblock, although is not certain of the length of the serial number 17 replacement breechblock in Borchardt-Luger 6. The 20 1899 preproduction Borchardt-Lugers submitted to the Swiss for field tests were identically configured with the square link toggle link assembly with the 51.25mm breechblock as used in Borchardt-Luger 5. If there were field tests problems with the subject clearance they were not reported as apparently the few Swiss test guns returned to DWM and refitted with the new radiussed middle and rear link yet retained the original 51.25mm breechblock. It wasn’t until M1900 Parabellum production that the length of the production breechblock was shortened by 1mm in the rear section to a total length of 50.25mm as a precautionary measure thereby maintaining or increasing the breechblock/coupling link tolerance gap at maximum recoil. The conclusions being that without shortening the rearward section of the breechblock, under extreme conditions resulting from continuous use could weaken the recoil spring, combined with other multiple coupling distortions could create further rearward breechblock movement at maximum recoil with resulting potential impact contact of the coupling link and the rear end of the breechblock and possibly subsequent failure. |

Items 2 and 3 above were a result of the Swiss critique of the November 1898 field tests of Borchardt-Lugers 4 and 5. The trigger, the removable left side frame panel and the retention of the frame magazine release button Riband style flat spring remained unchanged. The angle of the riband spring was changed slightly as a result of the relocation of the magazine button. Since the whereabouts and mechanical configuration of Borchardt-Lugers 7, 8 and 9 are unknown, one cannot say when the final changes were implemented. However, the 1899 pre-production Borchardt-Luger 10 essentially reflects the final design of the Luger.

1899 Borchardt-Luger 6 has survived to the current day as originally submitted to the Swiss in May 1899 save for a minor change to the frame which will be discussed later in detail. It should be pointed out that the toggle link assembly of BL6 as originally submitted to the Swiss in May 1899 was identical to BL5. It is the current configuration of the BL6 toggle link assembly that is the focus of this discussion.

Many of the changes to the BL6 frame design are discussed by Bobba1 and Sturgess. BL6 was submitted to the Swiss in May 1899 with a square middle and rear link interface toggle link assembly identical to BL5. All of the originally fabricated 1899 pre-production, prototype Borchardt-Lugers had the original design square middle and rear link interface toggle assembly. The original square interface toggle link on BL6 was replaced with a redesigned round interface after it was returned to the factory. It ended up with a hybrid assembly consisting of a replacement 1899 serial number 17 Borchardt-Luger breechblock mated with a newly fabricated middle and rear link.

The new replacement BL6 rear link was fabricated with a new middle and rear radius joint, yet retaining the original design toggle knob 4mm integral rear angle abutment and serial number placement. Also, a first with the new replacement BL6 rear link is the streamlining of the link underside in profile. The original design of the BL5 and 6 bulbous rear link underside was changed on BL6 to the more recognized straight line profile where the top and underside surfaces are parallel. The angled rear link abutment contact surface was changed from an approximate 12º-15º angle to a flat under side surface.

The submission of the Borchardt-Luger 6 to the May 1899 Swiss evaluations with the incorporation of the radius link is questionable since it comes immediately after BL5. In addition, there are no documented Swiss complaints regarding the square toggle link assembly resulting from the testing of BL5 nor as a result of the 1899/1900 Swiss test/acceptance trials. The only noted complaint concerning the toggle link was the frail straight wall rear link sight block.

Therefore, the theory espoused here to explain the changes from the square to the rounded middle and rear toggle link joints of BL6 is that DWM used BL6, after the May 1899 Swiss trials, for a test bed for the radius interface. BL6 was returned from the May 1899 tests in Thun with the same toggle link configuration as BL5. Following the trial of the twenty 1899 pre-production Borchardt-Lugers, the Swiss expressed dissatisfaction with the frail rear link sight. Therefore DWM redesigned the rear link. In doing so, it was decided that the interface joint would be less stressed with rounded corners. The design was changed and the drawing was modified as shown in Figure 10 of Sturgess' article. The toggle knob rear angled abutment of BL6 was left unchanged at 4 mm long. The new radius middle and rear link, the lengthening of the toggle knob from 4 mm to 5 mm and the strengthening of the rear link integral sight block along with a interim prototype trigger were incorporated into some of the twenty 1899 Borchardt-Luger series that were returned to DWM/Luger at the end of the 1899-1900 Swiss trials period. These changes required a complete new manufacture middle and rear link. These new middle and rear link designs were incorporated in the 1900 production model. The authenticated 1899 Borchardt-Lugers changed to the new configuration and subsequently submitted to the British for trials were:

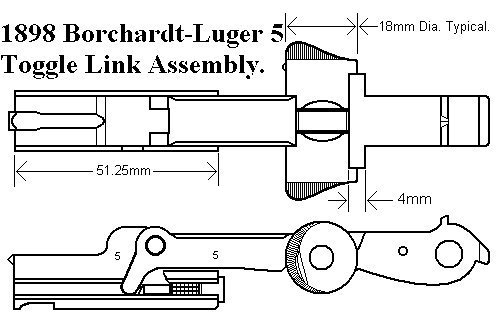

A cropped portion of a detailed 4" x 6" picture photograph of the rear frame of Borchardt-Luger 6 appeared on the cover of the 1993 NEUCHÂTEL "22nd Swiss arms fair" brochure. Coincidently, this was the debut of BL6 to the collecting world. The photo shows that the rear frame wall, above the lanyard loop, has been modified. Prior to being modified, BL6 was substantially similar to the BL5 rear frame wall. The BL5 frame has an angled abutment extending beyond the rear frame surface above the lanyard loop. The abutment is part of the integral rear frame guide rails for the bifurcated receiver forks. These features of the M1898 frame rear wall and rear link are clearly visible in Luger Swiss Patent 18623, approved January 2, 1899. Swiss Luger patent 21959 Fig 8 shows the final 1899 and 1900 production rear link abutment configuration. The purpose of the frame rear wall abutment extension was to engage the bottom edge of the rear link underside at maximum recoil and not the frame rear wall.

The frame rear wall extended abutment is clearly visible on the rear frame of BL5. It appears to also have been part of the BL6 rear frame wall.

The removal of the BL6 frame rear wall abutment extension does not look like a typical DWM tool room modification since the machined surface was left unblued. One possible scenario to explain the lack of rebluing is as follows. BL6 had been returned to DWM after the May 1899 trials. The Swiss test commission were not satisifed with the automatic grip safety, they indicated that it was difficult to operate with one hand and left it to Luger to modify the grip safety accordingly. Since it would not be practical to eliminate the added locking catch on the grip safety, Luger decided to use BL6 as a prototype unit on which to test a new rear link for possible inclusion in the design for the twenty 1899 models to be delivered in late 1899. Luger had another idea for the lockable safety. He redesigned the locking safety onto unlocking cam ear on the left side of the frame as shown in Swiss patent 21959. Therefore, Luger would not have wanted to use BL6 as a demonstration model for any future trials since the safety mechanism would be different. When the modified rear link was fitted to the gun, the removal of the extended abutment was required to allow the receiver and toggle assembly to function correctly. The machined area was not reblued because the gun would not be used for further trials as described above and DWM and Luger were too busy tooling up for the fabrication of the 1899 preproduction Swiss trials models for the Swiss trials. The factory would not have wanted to spend time on unnecessary tasks.

The modification of the rear link underside from angled to straight allowed for the rear link underside to engage the rear frame surface fully at maximum recoil. The original downward angled surface contact point was the rearmost underside projection of the rear link. The recoil impact was concentrated on a very small, focused surface area of the rear frame wall. The new flat surface underside of the rear link spread the recoil impact load into a larger area of the rear frame wall. The degree or severity of the impact area can vary from gun to gun and depends on several factors. The localized tempering of the rear frame impact area which can vary from frame to frame or the amount of rounds expended. In any event, the possibility of structural failure, from either style of rear link underside abutment shown, compelled the designer to eventually reinforce the rear frame area. About 1913, as a result of field failures effecting the rear frame wall structural integrity, the rear frame wall thickness was increased and the internal existing frame wall structure was further reinforced. The redesign strengthened the rear frame wall to better withstand the repeated impact pounding of the toggle link rear underside at maximum recoil.

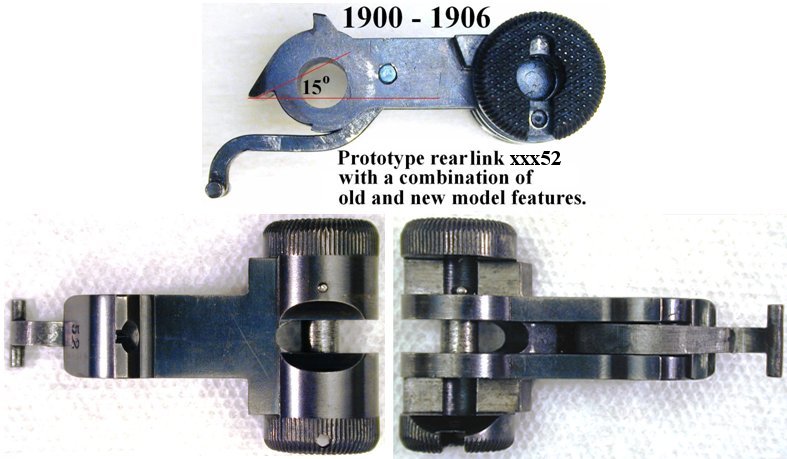

The angled abutment of the original BL6 rear link underside that contacts the rear frame wall at full recoil was changed to a straight abutment on the redesigned rear link and used on subsequent old and new model production. The angled rear link abutment strangely reappeared in the 10000B series 9mm prototypes, 10028B, 10030B, 10031B, 10070B, the 9 mm Cartridge Counter Lugers, randomly dispersed through the serial number range, 22406, 22411, 22414, 22428, 22432, 22449 and on a very unusual a transitional prototype rear link, shown below, with old and new model features possibly also of 9 mm caliber. This transitional prototype rear link is stamped 52 behind the sight. Complete 5 digit serial number possibilities being 10052B or 25052.

The 1900-1906 prototype old model style rear link has a retro 15º angled abutment with typical old model style flush top surface that is identical to the 1903 French Chargé rear link top surface. However, it has the new model square face with full shoulder toggle knob final design 60º or diamond hatching surface pattern of the 1906 new model production and not the interim partial surface toggle knob 90º hatching pattern of the 1903 French Chargé (Click for more information). The underside toggle knob channel walls are of the typical old model straight wall configuration, 1903 French Charge series and the 1904 Navy transitional Lugers vs. the slight 6º lower edge wall chamfer or shallow taper of the final new model production link. The toggle lock, although missing is identical to the 1904 transitional navy Luger toggle combination single assembly dual function toggle lock/spring with the exception of the navy toggle knob with 90º hatching pattern and not the transitional French Chargé Luger toggle lock which is identical to the old model toggle lock assembly with spring and center axis retention pin.

It is stated by Bobba that "At the end of the (November 1898) tests Luger left pistol no 5 in Switzerland and took no 6 with him to Berlin where he made several modifications to it…". Additionally, Bobba later quotes Regnier, the owner of BL6 as saying, "Regnier therefore concludes that Luger went back to Thun with the no 6 and 7 pistols…". In May 1899, further tests were conducted in Thun with two "improved" Borchardt-Lugers suggested by Bobba to be serial numbers 8 and 9 whereas Sturgess states that it was 6 and 7. Borchardt-Lugers 6 and 7 seem more reasonable in light of the current configuration of BL6 and the facts presented above. There is the possibly that after the May 1899 Swiss evaluation tests, DWM conducted further tests on the redesigned/reworked BL6. However, there is no mention of BL6 being resubmitted to the Swiss or any other country after the modifications to the frame and the rear link that occurred after the May 1899 tests. BL6 probably remained in the DWM tool room for many years.

The Toggle Link Assembly in the 1898/1899 pre-production Borchardt-Luger prototype through the 1900 production old model category has essentially four recognized variations, five if BL5 and the original BL6 are included.

Even with the additional small group of 1899 Borchardt-Lugers identified by Bobba in 1996 as being in the W+F collection, not a solitary example was identified with the original square link toggle assembly. Also the plain bordered grips never made it to production as even 1899 Borchardt-Luger 40 has fully checkered production-style grips described as original to the gun. See description of BL40 grips

Copyright © 2002-2008, Land of Borchardt, All rights reserved.