Text Resize

buttons

|

Click on crest to view Swiss Crest Application Theory

1899 Swiss Test/Acceptance Borchardt-Luger serial number 22 1899 Swiss Test/Acceptance Borchardt-Luger serial number 22

06/29 Luger serial number V4 06/29 Luger serial number V4

Please note some of the information and pictures presented in this article regarding the 20 1899 pre-production prototype Swiss Test/Acceptance Borchardt-Lugers have been discussed and pictured by several authors in books and articles, some in great detail. However recent discoveries have prompted a review and reevaluation of previous published information, and provided the author with enough new material to continue the story of the Luger.

The subject 1899 Swiss Test/Acceptance Borchardt-Luger serial number 22 (V4) has been part of the Land of Borchardt collection for several years and is discussed and pictured in the article below. 1899 Swiss Test/Acceptance Borchardt-Luger serial number 22 (V4) is also discussed and described by Dr. G. Sturgess in his recent three volume book series "Pistole Parabellum" by Görtz/Sturgess with much new and interesting information and is presented in Volume I, Chapter 5 in text and pictures on pages 145, 146, 147 Figure 158, page 148 Figure 159, page 149 and page 150 Figure 161.

Pages 145 thru 150

The gun is attributed to the D. Smith collection, being correct at the time of the beginnings of the book, however, since the Pistole Parabellum, being a three volume book series, a massive undertaking, took almost ten years to complete and publish, no doubt several credited items in the book have changed hands, such as 1899 Borchardt-Luger 22 (V4).

Contents

Background - The Final 1899/1900 Swiss Trials Tests

May 1899 - DWM and Luger were asked to supply at least 20 guns and a suitable amount of ammunition to permit full scale field trials in the autumn of 1899. These pre-production (prototype) pistols arrived in Switzerland in October or November 1899.1

It is necessary and helpful at this time to present a brief discussion of production vs. pre-production prototype fabrication to establish a baseline and to debunk any theories that suggest there are inevitable variations to be found in the 20 1899 pre-production prototype Swiss Test/Acceptance Borchardt-Lugers and that any such variations are the result of the prototype nature of the process. This argument is usually a proposition espoused by the mechanics to convince the client or collector to accept deviations of machining and omissions as legitimate variations.

Production vs. Prototype Fabrication

The fabrication of prototype parts is every bit as exact as the fabrication of production parts. In the process of producing prototype parts, the precision tooling is not available for alignment and setup for cutting and machining of the parts. Each step of the fabrication process involves the tedious setup of fixturing to align the machine tools for proper cutting of the individual parts. In order to produce a duplicate part, the blank (part being worked) has to be realigned to the cutting tool for precision machining. Whereas, once the parts are in production, tooling is developed so that each piece being machined is positioned quickly and precisely for each cutting step. Precision tooling takes time to develop and make and is not fabricated until the decision is made to warrant the expense and time involved in building the tooling and machine jigs necessary for repetitive production of parts. The outcome for parts fabricated by either process is the same in terms of quality, machining consistency and functionality. However, the time involved in fabricating prototype parts is much greater as compared to the time to fabricate production parts.

The Ordonnanzpistole 06/29 W + F

On 19 January 1929, construction of an experimental gun was agreed to by the Eidgenössische Waffenfabrik or Swiss Federal Armament makers (W+F) and the Kriegstechnische Abteilung or the Military Technical Office (KTA). The first 20 pre-production examples ( V1-V21) appeared in June. Tests were then undertaken between the experimental V series Ordonnanzpistolen and three other guns that were readily available commercially. The new 06/29 Swiss Parabellum was officially adopted for officers and some senior NCOs on 30 November 1930, however the first small batch deliveries were not until end of August 1933. 2

It seems that several of the V guns reworked were some of the original 20 1899 pre-production prototype Swiss Test/Acceptance Borchardt-Lugers as identified and pictured in a relatively recent publication,3 that had apparently been set aside (incredibility since 1899/1900) by the Eidgenössische Waffenfabrik. Reportedly, Swiss archives and current Swiss records show no evidence of any other similarly modified 1899 Borchardt-Lugers.

Versuchsmodell serial numbers V1, V3, V6 and V7 shown in Bobba’s book are reworked 1899 Swiss Test/Acceptance trials prototype Borchardt-Lugers 10, 15, 28 and 29 respectively, also considered by Bobba to be 06/29 experimental prototypes. Converted experimental V series Swiss Borchardt-Lugers 10, 15 and 28 amazingly still sport the "die struck" or hand stamped Swiss Cross and Sunburst on the chamber* and still retain the original, as manufactured thin profile, slab sided trigger. From the beginning, the Swiss did not favor the original thin trigger and per Bobba the Swiss were using these particular experimental Luger conversions to demonstrate or test certain qualities of the 06/29. Of the four 1899 Borchardt-Lugers mentioned, only serial numbers 10 and 29 still retain the original plain bordered Borchardt-Luger wooden grips. These particular V series 1899 Borchardt-Lugers are the only known surviving 1899 Borchardt-Luger Swiss Test/Acceptance trials "06/29" V series conversion examples and are currently part of the W+K permanent collection and barring unforeseen circumstances will never be part of any private collection.

1899 Swiss Versuchsmodell - Test/Acceptance Trials Borchardt-Luger serial number 22 (V4)

Recently identified 1899 Swiss Test/Acceptance Borchardt-Luger serial number 22 (V4) can be added to the short list of known 1899 Swiss Test/Acceptance Borchardt-Lugers reworked to a Swiss Model 1906/29 V series Luger.

Bobba states of the V series: On January 19, 1929, the KTA asked the W + F to develop a series of experimental prototypes of the new pistol. There is a certain incongruity in what has been said by the most reliable sources regarding the number and matriculation of these prototypes. It is said in fact that there were twenty of them, numbered from "V1" to "V21!" It is possible that in the beginning it had been decided to make a certain number of experimental pistols (the V in front of the number obviously stands for "Versuch") but all the numbers are not known, also because probably certain of these prototypes were later destroyed or in their turn cannibalized.

There was also a practice at the W+F: it was usual that the director who retired took home one or two pieces of his choice for which it's possible that certain pistols of this series followed a path of this kind.4

1899 Swiss Test/Acceptance prototype Borchardt-Luger serial number 22 (V4) is one of the circa 1929 V1-V21 series. The discussion continues with the addition of 1899 Swiss Test/Acceptance Borchardt-Luger serial number 22 (V4) into the mix.

Including private and museum collections, only one 1899 non Swiss pre-production prototype, plain chambered Borchardt-Luger is known to exist with both the original 3-1/2 turn trigger spring and the original thin trigger; serial number 40 which coincidentally is the highest known legitimate pre-production prototype. There are eight with the original plain bordered Borchardt-Luger wooden grips, 10 (V1), 21, 22 (V4), 23, 26, 29 (V7), 30, and 35, five with the original thin trigger, serial numbers 10 (V1), 15 (V3), 21, 22 (V4) and 40, five with correct DWM tool room transitional replacement triggers, 25, 26, 29 (V7), 30 and 35. Of these ten guns, seven are Swiss pre-production Test/Acceptance Borchardt-Lugers with a "hand engraved" 5 Swiss Cross in Sunburst chamber crest, 21, 22 (V4), 23, 25, 26, 29 (V7) and 30 and one plain chamber example, serial number 40.

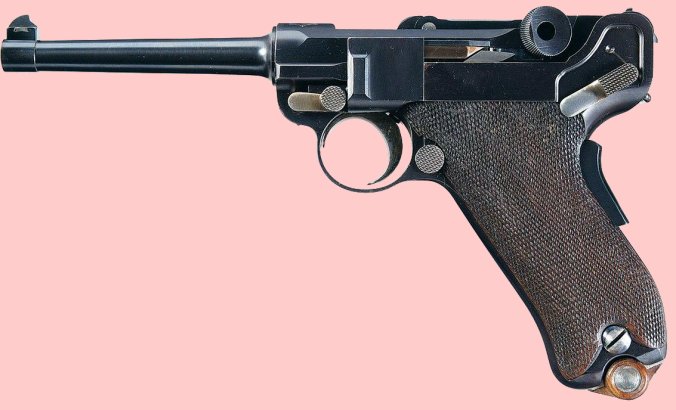

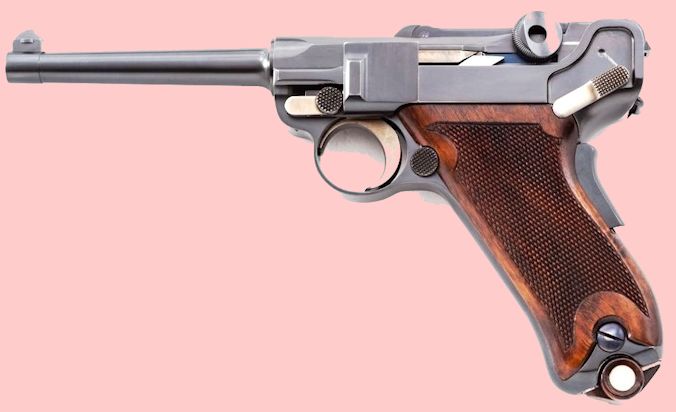

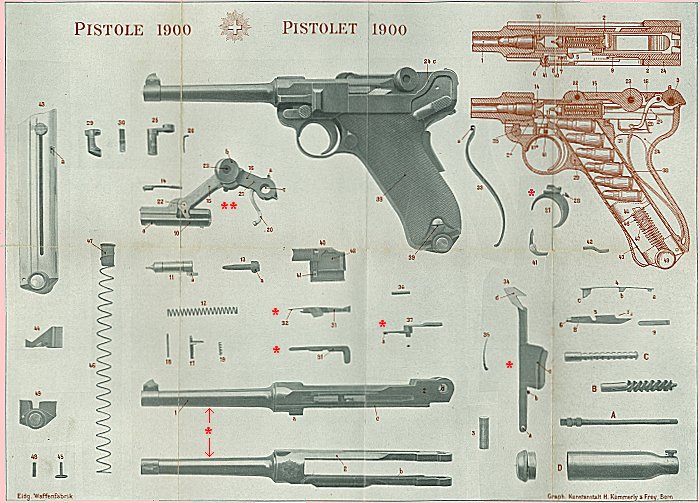

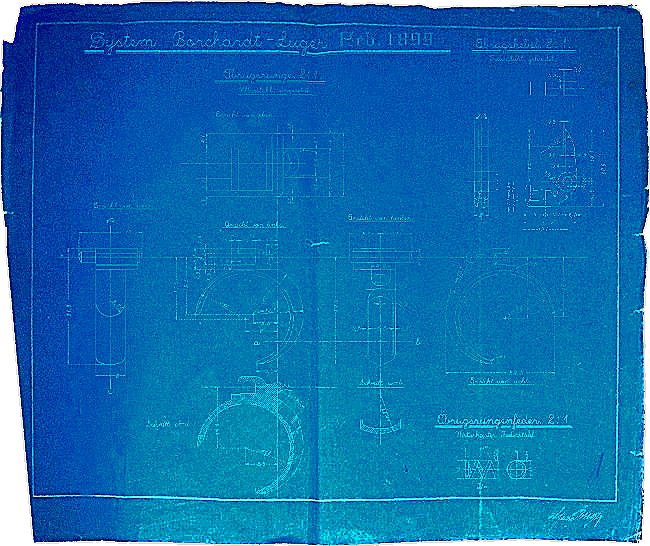

Following is a detailed description of 1899 pre-production prototype Swiss Test/Acceptance Borchardt-Luger, serial number 22 (V4). This was one of 20 1899 Borchardt-Lugers submitted by Georg Luger and DWM to the Swiss military in October/November 1899 for field tests. Also of additional historical significance, parts of this gun, namely the toggle link assembly, the hold-open device, and the receiver/barrel assembly were used to illustrate the Model 1900 Swiss Ordnance Pistol fold-out drawing in the Model 1900 German and French language version instruction manuals, titles being "Anleitung Kenntnis und Behandlung der Pistole Model 1900." and "INSTRUCTION SUR LA CONNAISSANCE ET LE MANIEMENT DU PISTOLET 1900", respectively.5a The above mentioned components of 1899 Borchardt-Luger serial number 22 are identified on the M1900 Swiss instruction manual fold out drawing by red asterisks shown below. Many of the other small parts shown in the drawing may also be from Borchardt-Luger serial number 22.

| Please note that the single red asterisk * noted parts are part of the current and original configuration whereas the double red asterisk marked parts were part of the original configuration that were replaced at a later time (** asterisk "Toggle Link Assembly") | |

This gun was subsequently later modified by the Eidgenössische Waffenfabrik per direction of the KMV (Kriegsmaterialverwaltung, War Materials Administration or the Swiss Army Materials Department) for experimental, presentation or training purposes and renumbered V4 for Versuch, Versuchsmodell or Versuchswaffen (Test, Test Model or Test Weapon Number 4). The V4 stamps are located on the left side frame rail, and on the bottom of the barrel and on the top of the rear link, of which the rear link uppercase letter V is larger (5mm height) than the number 4 (3mm height) and interestingly, both the larger letter V and the number 4 on top of the rear link are engraved or pantographed vs. stamped, as on the left side frame rail and the barrel underside. Additionally a W+K logo identified as the mark of the Eidgenössische Waffenkontrolle is stamped to the left of the V4 on the left side frame rail, being described as a capital W in the form of a circle containing a small capital K in place of the F 6. Various components of the gun were refinished/reblued where modified. Unmodified parts retain their original 1899 DWM tool room rust blue, examples being the narrow grip safety and the take down side plate. All the strawed parts retain their original heat temper straw. The gun frame was reblued, externally and internally at the time of the modifications. The bluing process used on the frame is similar to the process used on the Swiss production Model 06/29. The reworked receiver used a different bluing process and the entire barrel may not have been reblued, which will be discussed later in this article.

This gun was possibly used in two separate Swiss military test programs, the 1899/1900 Swiss Test/Acceptance trials and the 1929 Swiss 06/29 experimental prototype development program (this is less certain). These trials occurred more than 30 to 40 years apart. Therefore, some of the modifications identified and discussed herein could be from either era.

The Barrel and Receiver

The 1899 reblued receiver by the Eidgenössische Waffenfabrik retains the original hand stamped or "die struck" Swiss Cross in Sunburst on the chamber with the original serial number 22 stamped on the underside stop lug, which is a larger 3 mm font size than used on the component parts. The same 3 mm font size was used to stamp the two digit serial number 22 inside of each grip. The component parts are stamped with an exceptionally small 1.5 mm font with the two digit serial number tightly grouped. The small parts number 2 stamp has a flaw or defect that shows in all the stamped parts. The larger stop lug number font and the smaller stamp are correct and are identical in size and style to 1899 Borchardt-Lugers 19, 23, 26, 30 and 40.

Obviously the most recognizable feature of the 1899 receiver is the "die struck" Swiss Cross in Sunburst chamber crest, distinctively deeply struck into the chamber surface. 5 Although the receiver is reblued the crest retains all of the characteristics of the original hand "stamping" including the alignment dot, located in the center of the cross, of which coincidentally wouldn’t be needed or necessary if the crest was hand engraved. This simple mark, which is so conspicuously present on all the identified genuine and authenticated original 1899 pre-production Swiss Borchardt-Lugers and yet, consistently eludes the mechanics as the most recent example, Borchardt-Luger 20, being otherwise close to replicating the crest, lacks this most distinguishable feature.

The 1899 receiver can also be recognized externally, in profile by the rather wide transition flair starting on the receiver left and right side flat surfaces and terminating at the rounded receiver chamber/barrel interface vs. the narrower, shorter in length 1900 production receiver flare, which is more defined with sharper edges at the apex, terminating in parallel lines at the rounded receiver chamber/barrel interface.

Another feature unique to all 1899 Borchardt-Luger receivers has eluded the mechanics up to now because it is internal. Specifically, the underside of the receiver rails where the shallow taper of each receiver "fork" terminates flush to the chamber face. The underside of the old model production receiver rails shallow taper terminates 6 mm from the chamber face. Two examples that have the old model production taper are Borchardt-Lugers 8 and 20.

Approximately one millimeter of metal has been machined off the rear receiver sloped fork abutments to accommodate the 06/29 "new model" Swiss design toggle knob assembly. The assembly has 1 mm longer rear link integral angled abutments. The receiver also has the original installed strawed ejector with the serial number 22 scratched on the inside surface. The original strawed serial number 22 stamped receiver Sear Bar has been replaced with a 06/29 type blued Sear Bar, stamped E25 on the lower side. The E25 stamped Sear Bar has been determined to be an 06/29 Bern Swiss Ordnance replacement part as several 06/29 E25 stamped Sear Bars have been observed, with and without a Swiss inspection cross. If we assume the E25 stamped Sear Bar replacements were made available only after 06/29 issue and since the first delivery of the 06/29 wasn’t until August 1933, then the availability or use of spare parts is no earlier than the 1933 first delivery date. This suggests the Eidgenössische Waffenkontrolle testing or use of 1899/06/29 serial number 22 (V4) was in the mid to late 1930s. Also that the original strawed, serial number 22 stamped Sear Bar was part of the 22 (V4) assembly through 1933 and possibly later.

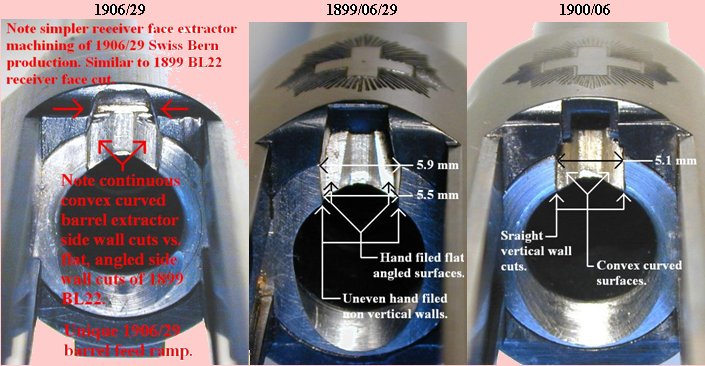

1906/29 Bern, 1899 Borchardt-Luger serial number 22 (V4) and typical 1906 Swiss Ordnance Luger.

Chamber faces, dimensioned.

The original 1899 barrel was removed from the receiver in order to modify the 1899 BL22 pre-production barrel and receiver chamber face, which is identical to the 1900 old model production barrel and receiver chamber face. The

existing old model extractor cut

of

the barrel chamber face was modified

to accept the

06/29 new model style extractor lower half angled tip projection.

The original 1899 old model receiver face

was also modified by adding

a simple angled, rectangular cut

to accept

the 06/29 upper portion extractor tip projection.

The 1899 Borchardt-Luger 22 (V4) receiver extractor cut

was a simpler machining operation compared to the earlier, more complex new model

1906 DWM production multiple straight chamber wall receiver extractor cuts.

The 1899/06 added receiver cut is basically identical to

the 06/29 stepped receiver production cut,

which was apparently, one of the many simplified machining steps incorporated into the 06/29.

The original sight blade was replaced and

the 22 serial number on the barrel was removed and V4 added along with a Bernproße proof. The barrel was reinstalled to the receiver, aligned to the original witness marks. The Bernproße proof was added after the gun was totally reconfigured and test fired.

In the book Pistole Parabellum by Görtz/Sturgess, volume 1, page 149, Sturgess discusses the special holsters supplied with some of the 20 1899 Borchardt-Luger trials guns submitted by DWM-Berlin to Switzerland in November 1899 for extended tests. He discusses at length the holster that was with 1899 Borchardt-Luger 30 with a brief, obscure, rather serendipitous, reference to a second trials holster in the last sentence of a lengthy single paragraph: A second identical example of this holster with the same cleaning rod is known which originated in Switzerland, showing this holster with sn 30, as might be expected, to have been the original Swiss trials pattern holster, returned with the pistol to DWM and then shipped to the UK. In this last sentence he is apparently referring to a picture in an article on these special holsters presented in the LOB web site holster directory under “Swiss holsters”, written in October 2005, a few months after the acquisition of this “second” 1899 Borchardt-Luger trials holster.

Typical 1906 Swiss Ordnance Luger chamber face, 1899 Borchardt-Luger serial number 22 (V4) and typical 1900 Swiss Ordnance chamber face.

It is interesting to note that the subject Swiss barrel/receiver conversion of an old model extractor system, in this case an 1899 "old model" to a new 06/29 model extractor system, that the Swiss did not make any attempt to replicate the DWM supplied new model 1906 Ordonnanzpistolen or their own indigenous W+F Bern receiver chamber machining, which involved flattening the top of the receiver chamber for better extractor visibility when loaded. Either the Swiss recognized the historical significance of the hand stamped Swiss

crest and didn’t want to disturb it or simply thought it over complicated and not necessary for their then current purposes or test goals.

The original barrel sight blade, as stated above, has been replaced with a wider blade to correspond with the "U" shape notch in the 06/29 "replacement" toggle link assembly V4 stamped rear link. There is an alignment mark on the top right forward section of the sight block but no corresponding mark on the sight blade, only a faint stamped "+". There is an added alignment mark on the top left forward section of the sight block and a corresponding mark on the sight blade, which coincidently do not align with the sight blade, being offset to the left. There are other 1899 Borchardt-Luger V series shown in Bobba’s book with same sight blade alignment mark offset.

The barrel is determined to be the 1899 original based on the white metal muzzle crown surface which is rather flat compared to the later 1900 production convex surface muzzle crowns which are distinctly more pronounced. Since there are three different sight block base alignment marks, this suggests possibly the use of three sight blades. The top right surface sight block alignment mark is the DWM original mark. The current installed sight blade with the top left side sight block added alignment mark with corresponding sight blade alignment mark was added next and a poorly struck third witness mark was added to the front surface of the sight block. There is no corresponding mark on the front rearward sloped surface of the current replacement sight blade, usually found on the "Pistole, Ordonnanz 06/29" production installed sight blades. The sight blade replacement scenario described is not unusual for an 1899 Swiss Test/Acceptance Borchardt-Luger as the one of the obvious 1899/1900 testing goals was the shooting accuracy.

On the barrel underside at the receiver end, about an inch in length along the barrel axis and covering approximately 180º of the lower barrel surface is a slight difference or lighter appearance in the bluing. This area is where the original Borchardt-Luger barrel was refinished after removing the 22 serial number and adding the V4 and Bernprobe proof. Based on the difference in the finish surrounding the V4 stamping and Bernproße proof stamping, the balance of the barrel finish is 1899 original or at a minimum, a different finish. Also a less noticed but significant feature that errs toward the barrel being the 1899 original can be found on the barrel chamber face, specifically being the distinctive barrel feed ramp machining, which is typical old model.

The Frame

The 1899 Borchardt-Luger serial number 22 frame was modified by replacing the old model Riband dual flat recoil mainspring assembly with the new model coiled mainspring assembly using 06/29 production Swiss proofed parts. The frame cam ramps were modified by extending the forward edge of the frame cam ramps approximately 5 mm. This created a shallower ramp by extending the slope and thereby creating an initial, smoother toggle knob breaking. This was done by adding two new hardened inserts, dovetailed and soft soldered or welded into the original cams. So perfectly fitted in this case, they are not visible even on the reblued inside faces. The only indication of modification is a test hardening point mark located in the left side frame cam ramp lip or ridge replacement area and the associated remachined recess area. There is also an unusual hole or void, vertically positioned under the forward most extension of the right side rear frame added cam ramp lip, which could be the remnants of an alignment pin or, more than likely, welding. Four other V series 1899/06/29 conversions pictured in Bobba’s book, serial numbers 10 (V1), 15 (V3), 28 (V6) and 29 (V7) appear to be similarly modified by the W + F when viewed externally. V series 1899/06/29 conversion (V12), serial number unknown, does not have modified cam ramps. Although identified as an 1899 Borchardt-Luger, V12 does not exhibit any 1899 Borchardt-Luger characteristics and appears to be a W + F reworked 1906 Swiss Ordnance Luger with a replacement (pre-production prototype?) 06/29 barrel.

The Borchardt-Luger serial number 22 barrel bore rifling land and grooves are well defined and visible and the barrel lining is bright with no pits or corrosion. The barrel has expended a lot of rounds, yet there is no appreciable associated wear on the replacement 06/29 toggle knob rear contact surfaces and the corresponding contact points of the 06/29 type modified frame cam ramps, suggesting the barrel wear is mostly a result of the 1899/1900 Swiss trials tests, or the lack of contact wear could be a testament to the new design V series shallower cam ramps resulting in lesser contact point wear. The original design 1900/06 cam ramps in some cases tended to flair or flatten out with extended firing, a situation which seems to have been mostly eliminated in the new design 06/29 frame cam ramps.

The serial number 22 was removed from the rear of the frame and the W+K logo and V4 were stamped on the left forward frame rail. The frame can still be recognized as an 1899 pre-production Borchardt-Luger by the following unique characteristics:

- The rectangular cut and lack of an indent/stepped cutout for the left side magazine seam.

- The lack of a chamfer cut in the left side trigger guard for ease of installation and removal of the trigger/spring.

- The frame still retains the original prototype design 1st issue original strawed finish flat Thumb Safety. The 1899 pre-production Borchardt-Luger thumb safety is approximately 15% thinner in profile over the entire length versus the final 1900 production version; 3mm versus 3.5mm in thickness of the upper hatching/grasping surface and 1.3 mm of the 1899 versus 1.5mm of the 1900 production version for the lower curved section. Note that both the 1899 and 1900 thumb safety levers maintain a smooth, plain, convex curved surface in the lower section , not a flat surface with rounded and softened edges. The hatched grasping surface is also convex.

- The polished bright frame thumb safety recessed area has an incised border around the upper periphery, unique to all identified genuine original 1899 Swiss Test/Acceptance Borchardt-Lugers.

- In the upper rear frame trigger guard recess is a center located, 5mm wide indent or recess cut-out for the original narrow trigger 3-1/2 turn spring.

- An obscure but significant internal machining characteristic located in the 1899 Borchardt-Luger 22 rear frame cavity is a semi-circular depression resulting from terminating the machining operation while still in the metal of the frame. The recess is clearance for the upper section of the flat Riband type recoil spring at maximum extension. The walls of the depression are clearly defined, with the cut-out being distinctly lower, especially the rearward edge being approximately 1mm lower than the surrounding metal. This feature is unique to all genuine examined 1899 pre-production Borchardt-Lugers and most definitively in the rear frame cavity of 1898 Borchardt-Luger 5 and 1899 Borchardt-Luger 6 (less clear but equally definitive) showing excess metal surrounding the semi circular depression.

Interestingly, Figure 5 in Swiss Patent 21959 illustrates some internal machining and accurately depicts the same rear frame cavity semi-circular depression found in Borchardt-Luger 22 and other examined 1899 Swiss Borchardt Lugers

even though it is a line drawing and not a fully dimensioned engineering drawing for the 1899 Borchardt-Luger. The same patent line drawing is used in the 1900 Swiss instruction manual fold out "cut and paste" line drawing and the 1901 Borchardt-Luger instruction manual on page x, figure 3.

Weight was not an issue with BL5, but was with the 1899 pre-production frame as additional metal was removed from this area.

The 1900 production rear frame cavity has the same relief cut for the recoil spring and the cut can be either circular or rectangular with a straight line rear portion termination, both terminations basically flush to the surrounding area. However, the semi-circular depression discussed above is uniquely exclusive to the rear frame cavity of the 20 1899 pre-production prototype Swiss test/acceptance Borchardt-Lugers.

- A subtle but definitive 1899 Borchardt-Luger external frame characteristic is the virtually seamless blending and perfectly smooth, continuous transition of the junction of the lower rear flat surface of the trigger guard with the convex surface of the forward grip strap which is a result of the attention of hand finishing versus the more noticeable 1900 production terminations. This attention to detail is evident in all aspects of the 1899 pre-production series Borchardt-Lugers, including 1898 Borchardt-Luger serial number 5.

The only frame modification that eludes an explanation, as of this writing, is the presence of the numbers 5, 7 or 57 stamped in the forward lug well, which was not part of the original 1899 assembly. Although, the number font style and placement is similar to the Ordonnannzpistole 06/29 W+F practice of stamping the date of manufacture in the forward lug well.

There is no doubt as to the originality of the Borchardt-Luger 22 plain bordered wooden grips. The color and appearance is of the classic golden color, warm pleasing hue and unique grain pattern, being identical in all aspects mentioned, to the earlier Model C93 Loewe and DWM manufactured Borchardt pistol grips with identical exterior finish and appearance, interior grip wear patterns, age related stress cracks, etc.

Borchardt-Luger 22 plain bordered wooden grips have the correct proportioned plain bordered grip margins, instantly recognizable in other genuine surviving Borchardt-Luger grips including Borchardt-Lugers 5, 6, 10, 14, 23, 26, 29, 30 and 35. This old world finish and appearance, along with the proper plain border to hatching area width ratio is apparently, difficult to replicate. The grips of Borchardt-Luger 20 are a classic example of the mechanics' failure to replicate the original 1899 Borchardt-Luger grips, dimensionally and in color. There are identified early after market plain bordered Borchardt-Luger grips that have pretty much got the border ratio correct but cannot as yet replicate the early finish, color and wood grain pattern.

As a matter of note, the highest known legitimate 1899 Borchardt-Luger is serial number 40. It has fully checkered walnut grips as defined in an article by Dr. G.L. Sturgess stated to be original to the gun: …and the fitting of (unnumbered) production M1900 style unbordered grips (which have minor differences to the [hand] carving of the internal fitting, but are similar internally to those of the M1899 pistols).7a The description strongly suggests the wooden grips of BL40 are original DWM tool room installed grips as originally fabricated for BL40 and not M1900 production replacement grips and as described represent the first 1900 production styled 100% checkered walnut grips installed on a Luger. There is little doubt that the plain bordered grips found on most of the M1899 preproduction prototype pistols were discontinued sometime after the fabrication of 1899 Borchardt-Luger 35 and 40, i.e. discontinued prior to M1900 Parabellum production. There are no known legitimate, authenticated 1900 Production Lugers, Swiss or commercial, as of this writing identified with genuine M1899 style plain bordered wooden grips.

Another significant internal feature of the 20 1899 pre-production Swiss Test/Acceptance frames is the hollowed out lower forward gripstrap toe. Two identified 1899 "pre-production" frames, 1899 Borchardt-Luger serial numbers 8 and 20, have been observed with a solid filled lower forward gripstrap toe. An X-ray of 1899 Borchardt-Luger serial number 8 was taken and revealed that the lower forward grip strap toe was actually hollow. A curved plate was added and blended into the forward gripstrap wall contour to give the appearance of being solid. There are no verified 1899 pre-production Borchardt-Lugers with a solid forward gripstrap toe with the exception of Borchardt-Luger 35 and in that case the toe shows more metal but with a coarse depression, not the continuous blended straight wall appearance of Borchardt-Lugers 8 and 20, which is a concocted view of what the mechanics thought a solid fill forward gripstrap toe should look like. There is only one 1899 Borchardt-Luger in the 1899 preproduction series that has been identified with a forward gripstrap solid toe, that has not had the metal removed or “hogged” out and that is 1899 Borchardt-Luger 35. For more about BL35 click here. This solid filled toe subject has been discussed in a European publication by a noted Luger expert and collector.7 With that said there is another feature common to both 1899 Borchardt-Lugers 8 and 20 and that is both sport 1899 narrow thin profile triggers that have features, internal and external, totally different from the original 1899 Borchardt-Luger thin triggers of serial numbers 19, 22 and 40. See the section on triggers for details.

Regarding the lack of the trigger guard relief cut for ease of installation or removal of the trigger and spring on serial number 22, it has always been assumed that this feature or additional machining step was first permanently added to 1900 production frames and was initially lacking on all the 1899 pre-production Borchardt-Lugers. It has been suggested that some surviving 1899 Swiss Test/Acceptance Borchardt-Lugers with replacement interim production triggers and added trigger guard relief cuts were done after some of the 20 being returned by the Swiss to the DWM Berlin tool room. It is generally accepted that the original issue square link interface toggle link assemblies were also replaced at this time. It has also been suggested that they were provided to the Swiss by DWM as "upgrading kits" 8 rather than being replaced by the DWM tool room directly. If upgrading kits were used, then certain unidentified guns were not returned to DWM and the trigger guard chamfer relief cut was added by the Swiss. This theory is contradicted somewhat by the existence of 1899 Swiss Test/Acceptance Borchardt-Luger serial number 29 (V7), currently in the W+F collection with a replacement "production" trigger, yet lacking the left side frame trigger guard relief chamfer. 1899 Borchardt-Luger serial number 8 is rather retro in this regard as it has the "original" square link interface toggle link assembly vs. the radiussed interim toggle link assembly, yet with an "added" left side trigger guard frame chamfer.

1899 Borchardt-Luger serial numbers 19 and 40 are stated to be the only surviving pistols to be in "mostly" unaltered configuration as fabricated by DWM in 1899. Externally viewed, serial number 19 has a replacement Swiss manufactured breechblock replacement extractor, a replacement Swiss proofed barrel and production style magazine. Both have the early narrow trigger with a special 3-1/2 turn trigger spring. However, serial number 19 lacks the trigger guard chamfer relief cut. Assuming total originality of both guns in this area, the conclusion is that the trigger guard chamfer relief cut was first introduced in 1899 by DWM and serial number 40 is the only known example with this cut. An alternate scenario to explain the trigger guard relief cut present on serial number 40 is that it may have made a second visit to the DWM Berlin tool room before arriving in England.9 The chamfer relief cut on serial number 40 is slightly different than on 1899 Borchardt-Lugers 26 and 30. The location of 1899 Borchardt-Luger serial number 19 is unknown since it was last pictured in a 1975 Swiss publication10 some 36 years ago. Therefore, its current configuration is unknown and leaves 1899 Borchardt-Luger serial number 22 (V4) with the original thin, side profile trigger and no frame trigger guard relief chamfer as a sole survivor with this feature. There are three other examples shown in Bobba’s book that externally viewed, appear to have the same features as 22 (V4); serial numbers 10 (V1), 15 (V3) and 28 (V6). However, they are part of the W+K permanent collection and are currently unavailable for examination to verify certain relevant internal features.

Most of the changes to the final production 06/29 were mainly of a cosmetic nature, relating to weight reduction, simpler machining techniques and to reduce production costs. The only evident change to serial number 22 (V4) that is truly mechanically functional and affecting the operation of the Luger is the change to the rear frame cam ramps, which was incorporated into the final 06/29 design. Since the conversion of 22 (V4) to an 06/29 new model Luger used Bern Swiss proofed production parts, this suggests the modification was done years after the introduction of the Model 06/29. Too late to be part of the development program, the use or purpose of the 22 (V4) conversion was possibly of a non-experimental or prototype nature, perhaps for training or presentation purposes.

There are apparently other non V series, but very similar W+K (barrel) marked old model Swiss Ordnance Lugers such as Model 1900 Swiss Ordnance Luger serial number 980 with new model recoil spring conversion and 06/29 installed toggle link assembly and having similarly modified rear frame cam ramps. The serial number 980 modified cam ramps are slightly longer or more substantial in profile than serial number 22 (V4). The frame modification from the old model recoil to the new model recoil of serial number 980 included an additional change, more extensive than 1899 Borchardt-Luger serial number 22, with the serial number 980 left side frame gripstrap magazine channel cut-out being extended upward to just under the frame panel making the cut-out identical to the 1906 or new model Luger. Serial number 980 is not one of the 1929 W+K experimental 06/29 guns. It lacks the V prefix serial number and additionally the 06/29 middle link is a later sub-contractor part stamped with the S.I.G. Neuhausen logo. This places the modification of serial number 980 beyond the narrow purported 1929 time frame possibly to as late as the early 1940’s based on the time frame interpretation of the application of the W+K stamping on the barrel. The V4 stamped 06/29 "production" toggle link assembly of 1899 Borchardt-Luger 22 is production proofed, but without the S.I.G. Neuhausen logo suggesting initial early pre-production manufacture; possibly by Waffenfabrik Bern.

One advanced collector has suggested the Swiss conversion of several of the 1899 Borchardt-Lugers to 06/29 V series was done due to the unavailability of "in house" inventory of existing Swiss Ordnance Lugers, such as the Model 1906 DWM Ordonnanzpistolen and indigenous Waffenfabrik Bern Model 1906/24. With the existence of V12 pictured in Bobba’s book and the newer identity of V11, which is coincidentally similar to V12, being a 1906 Swiss Ordonnanzpistolen, along with 1900/06 W+K barrel marked Swiss Ordonnanzpistolen serial number 980 and other yet identified non 1899 Borchardt-Luger series modifications, make the "lack of inventory" theory not completely accurate.

Eidgenössische Waffenkontrolle

Another confusing issue is the status or meaning of the W+K stamp or logo, a.k.a. Eidgenössische Waffenkontrolle or the Swiss Federal Weapons Control stamp. The stamp is located on the left side frame rail of the converted 1899 Borchardt-Luger 06/29 V series and others in the identified V1-V21 series 06/29 "experimental" lugers. Bobba describes the W+K stamp on the left front frame rail as the circular trademark of W+F, (Bobba is describing the W+K mark) which appears for the first time on that model. a later section where he is describing the Transitional 24/29 prototype, with the same W+K mark and the serial number 33092 stamped on the left side frame rail, he states, The serial number is also present on the frame, behind the trigger plate, as then happened regularly on the 06/29. In front of this number, the mark of the Eidgenössische Waffenkontrolle appears: a capital W in the form of a circle containing a small capital K and a Geneva cross. This mark copies the W+K one, the only differences being the small K in place of the F. The strange thing is that this mark appears for the first time around 1942!11

The W+K stamp is yet identified in another publication12 as "the mark of the Eidgenössische Waffenkontrolle or Swiss Federation Ordnance Control stamp with the initials being WKT being used 1943 through 1947." The "+" being misinterpreted by the author as a T in the description does not change the interpretation. The presence of the W+K mark applied to 1942 and later manufactured M06/29’s is verified by two typical examples; 06/29 serial numbers 6707413 (1943) and 7498714 (1944).

Another noted Luger collector and author suggests yet another equally confusing scenario to explain the W+K mark on the 1899 Borchardt-Luger V series and the M1900/06/29 sn 980 conversion: The key lies in the barrel markings, since the W+K Waffenkontrolle marking was only introduced in 1942/43 as the P06/29 was reaching the end of its production run. The mark on the front left frames of the converted 1899 Versuchspistolen illustrated by Bobba is the "Waffenfabrik Bern W+K stamp" which is a "trade mark" or manufacturer's logo like the DWM monogram, not the W+K mark, which is the Federal acceptance mark signifying the gun meets the appropriate specification. The W+K mark on the Model 1900/06/29 Swiss Ordnance Luger barrel is a further acceptance mark for the spare barrel alone: BP is a pressure proof, + is an Army acceptance/property mark, while W+K is the Federal acceptance mark.

The production 06/29 Luger frame serial number is located on the left side frame rail along with a Swiss factory control inspector "control" mark, + over M (Mühlmann) to the left of the serial number, instead of the W+K mark located in the same position on the 1899 Borchardt-Luger and other Luger V1-V21

series circa 1929 and later 06/29 prototypes. The encircled W+K logo for Waffenfabrik Bern is stamped on the rear frame below the lanyard loop, and is distinctly different than the W+K mark.

All the W+K marks noted are identical on the "1929" V series, the transitional 24/29 serial number 33092 and the M1900/06/29 serial number 980 barrel. This is contrary to statements in several publications, some cited herein, that this mark was not introduced until 1942. Then, by inference, the V1-V21 experimental series cannot be 1929, which is also in complete contradiction to multiple publications.

The Magazine

The right side frame wall at the butt has been slotted to accommodate the new style domed, hatched surface follower button magazine. The inside original shallow channel of the right side plain bordered Borchardt-Luger wooden grip has been deepened to allow for the insertion of the new style higher profile, stepped follower button. In addition, a small section, on the right side interior wooden rib that runs the length of the grip was removed in the area and above the added gripstrap cross section reinforcement for the new model recoil system.

However, the Swiss disc domed follower button magazine that is currently in serial number 22 (V4) has had the stepped follower button uniquely modified. The hatching pattern was machined off a DWM manufactured Swiss 1900 production domed follow button leaving a shallow step smooth surface. The follower button base thickness has been reduced and the larger diameter of the follower button base circumference has also been changed. It was machined from the original 9mm diameter to 8.75mm diameter, leaving the modified follower button the same height of the original first design cross hatch surface flat follower button but with a smaller base diameter. Due to the circular machining on the smooth follower button surface, the machining was done with the follower button removed from the follower. This is substantiated by the Swiss disc wooden bottom, which shows evidence of the retainer pin being removed and reinstalled. The modification of the follower button is unusual. The modified magazine can be inserted in an unmodified original unrelieved Luger. The existence of the magazine in Borchardt-Luger 22 is unusual since the left side frame and wooden grip existing shallow channel of serial number 22 has been modified by adding a slot to the frame and the existing wooden grip channel deepened to fit the new style type 2, DWM provided Swiss production unmodified domed follower button magazine. In other words, the original 1899 prototype flat follower button Borchardt-Luger magazine, the early type 1 1900 production flat follower button style magazine or the final type 2 style 1900 domed follower button magazine. Both production versions of the wooden bottom magazine with steel disc inserts, requested by the Swiss as a result of the 1899/1900 test trials, will fit serial number 22 (V4).

The first thought is that this 1900 production final style Swiss magazine was modified by the Swiss, specifically to replace the flat follower button magazine in an original unrelieved gun. In this case in 1901 or later when the Swiss received the first deliveries of the new style magazines and years before the V4 conversion, 1899 Borchardt-Luger serial number 22 was modified. The Swiss performed their own magazine experiments using Borchardt-Luger 22. Since they did not want to modify the gun, the Swiss simply modified a final design DWM stepped or domed magazine follower button to fit into the then unrelieved 1899 serial number 22 frame and right side grip original existing internal shallow channel. Thirty or forty years later when the Swiss modified some of the 1899 Borchardt-Lugers, including serial number 22, to the new model style recoil system, the right side frame and wooden grip inside channel were then milled deeper to fit the new style magazine domed follower buttons, which were then the only type used. Not wasting any parts the Swiss naturally left the original magazine, which was totally functional.

Of all the surviving 1899 Borchardt-Lugers, including the Swiss Test/Acceptance guns there is no identifiable 1899 pre-production configured, provided magazine, or at least not available for this article. Interestingly, the 1898 and 1899 prototype magazines have been definitively identified, the most notable external feature is a unique wooden bottom retainer pin with domed or convex white metal surface ends. Location of magazine release slot is different in the 1898 and 1899 magazines. The 1899 Borchardt-Luger serial number 6 is shown with a flat follower button, plain wooden bottom magazine with a production style heat tempered blue, flat, flush surface wooden bottom retainer pin.

1899 Borchardt-Luger prototype magazine stamped 1 would be the more probable or appropriate magazine originally provided or used with 1899 Borchardt-Luger 6.

The Hold-Open Device

Shown are two dimensioned hold-open devices. The upper hold-open being a typical 1899 Borchardt-Luger 22 example and the lower hold open being a typical M1900 production example. Both hold-open devices are slightly different when viewed from an appearance point of view, especially in the method of the flat spring retention. Dimensionally the differences are insignificant in fit and functionality. Both hold-open devices are completely interchangeable and functional. The 1899 hold-open fits into a 1900 production frame and the 1900 production hold-open fits and operates properly in an 1899 Borchardt-Luger frame, namely BL 22. The upper right side frame cut-outs and slots for the hold-open devices are machined and dimensioned identically in the 1899 and 1900 frames.

When both the 1900 production hold open device and an 1899 pre-production hold open device are compared against the original 1898 Borchardt-Luger serial number 5 hold open device, all three are essentially mechanically identical with minor dimensional differences. The only dimension that could be considered as somehow significant is the lower edge of section C shown on the dimensioned hold open drawing of the 1899 BL22 hold open that contacts the magazine follower button. When the magazine is empty, the magazine follower button pushes the hold open device up to block the breechblock. The 1899 pre-production Borchardt-Luger hold open serial number 22 section C lower edge that contacts the magazine follower button is curved and slightly deeper, 8mm in height versus the flat 7.35mm height of the lower straight edge, non angled lower contact surface of the 1900 production hold open device. The 1900 production hold open device is interestingly the same as the 1898 Borchardt-Luger 5 hold open lower contact surface.

When the Borchardt-Luger 20 hold-open latch is viewed from the top in the frame, the magazine seam angled relief cut machining is curved and the slot is longer in width than the straight wall 90uare cut and standard slot width of the 1899 Borchardt-Luger 22 hold-open latch. The 1899 Borchardt-Luger 22 hold-open latch is typical of all other 1899/1900 hold-open latches.

A possible reason for the slight angle in the BL22 hold open device lower edge contact surface is so that the hold open/follower button contact would be closer to a 90 degree angle or perpendicular to the magazine (grip) axis and the lower contact surface of the hold open device, thereby minimizing any "side load" to the magazine follower button and frail 2.2 mm diameter threaded shaft. By production, the lower contact hold open angle was eliminated as unnecessary as the angle was not deemed critical and also seeing that the magazine follower button is circular which would also make the angle less critical. The increased height was also not considered as necessary as the only effect the increased height would appear to have is a more positive hold open activation, which was apparently considered adequate. Changing the method of the hold open flat spring retention was simply more practical, reliable and expeditious for production.

Flat Follower Button Magazine Mechanics

Even though the reasons Bobba mentions for the changing of the flat follower button to a domed follower button are valid 22, there are, in the author's opinion, more reasons than mentioned for the change. One has to be knowledgeable of the purpose of the follower button other than mentioned by Bobba to appreciate the multiple effects of the redesign. The Swiss were encountering other problems with the flat follower button other than the thin lateral surface of the Type 1 follower button. The very frail, small diameter threaded follower button shaft tended to "loosen" due to vibration and shock during repeated use. When the threads backed out, albeit by only a small amount, it caused the end of the shaft, which was pointed, to partially disengage from its seat in the inside surface wall of the left side of the follower. This in turn reduced the ability of the follower button shaft to resist shear pressure and eventually break. The ability of the small diameter threaded follower shaft to resist shear was encountered by the sudden stop of the follower button shaft when it hits the upper end of the magazine body channel and when the lateral circumference surface of the very thin follower button impacts the bottom of the hold open device. Both these impacts were encountered after the last shot was fired and the hold open device was activated by contact with the top edge of the flat follower button, pushing the hold open device into the path of the breechblock, thereby blocking the forward motion of the breechblock.

At this point in the magazine design, the only thing that kept the follower from exiting the top of the magazine was the integral tabs on the lower part of the magazine follower. The follower’s upward movement was stopped when these tabs encountered the two inwardly protruding magazine body crimps near the top on the left and right inside magazine walls. Any failure, such as a slight bulging of the magazine body, would allow the shaft of the follower button to hit the maximum upper travel of the right side magazine body shaft channel. One can see many examples of the old and new model magazines where the top of the magazine shaft channel is distorted. In all likelihood some of this damage was incurred by the loading tool slipping and allowing the spring loaded follower button to slam shut at high impact. It is not hard to visualize damage done to the frail flat follower button assembly. The "fixes" to increase the follower button shaft diameter from 2.16mm to 2.96mm, and riveting or "peening" the stepped end of a larger diameter unthreaded shaft into a hole in the follower body via an access hole added to the lower left wall of the magazine body. The Type 2 redesign of the follower button itself solved multiple problems. The question is, when DWM increased the lateral thickness of the flat follower button from 1.25mm to 2.33mm why did the upper portion of the button have a smaller diameter, 6.91mm vs. 8.93mm of the lower portion? The first thought was that it was done to minimize the modification of the frame to only one cut at the bottom of the grip and to deepen the channel cut in the wooden grip to allow the fatter magazine follower button to clear. A new follower button without the step would require a more complicated machining operation at the top of the right side frame to allow the fatter button to activate the hold open device.

The step in the new follower button therefore serves two purposes; to eliminate the above mentioned additional machining and most important, to minimize the impact of the lateral surface of the follower button by having the impact absorbed by the frame, and this is what happens after the last shot is fired. The hold open device is activated but the follower button's upper travel is now restricted by the frame, not by elements of the magazine. The hold-open device is now conveniently elevated into the path of the breechblock only enough for optimum effectiveness. Before the redesign, the only restriction as to how far the hold open device would be pushed into the frame channel was the structural integrity of the integral tabs on the lower part of the magazine follower, acting against the two inwardly protruding magazine body crimps near the top on the left and right inside magazine walls and the flat follower small diameter shaft contact with the upper travel limit of the magazine body channel.

The Trigger

The original thin side profile trigger of serial number 22, which is the most characteristic feature of an original M1899, has not been replaced. The inside rear area of the frame trigger guard still retains the original narrow 5mm wide center located recess cut for the frame trigger spring retention. Please note that the serial number 22 trigger right side profile is slab sided with one continuous width, left and right side. This is the same as the original triggers of 1899 Borchardt-Lugers 19 and 40. In other words, there is no step, blended or otherwise, in serial numbers 19, 22 and 40 triggers. Triggers with a blended step on the right side and additionally with an internal configuration, more production than prototype has been noted on two observed 1899 Borchardt-Lugers, serial numbers 8 and 20.

In defense of the serial number 8 trigger and by association the recently published picture of the serial number 20 trigger15, a Luger expert, dealer and gunsmith, who is "intimately" familiar with the 1899 Borchardt-Luger 8 pistol suggests that these are interim pre-production Swiss designed triggers identified in the Bern Archives. However, a translation of a section of the April 2, 1900 published Swiss 1899/1900 field test reports of the Bern Archives, relating to the trigger suggests otherwise: "The trigger modified (designed) by the Eidgenössische Waffenfabrik is given preference since the index finger slides downward more easily and therefore increases the leverage of the trigger. It has, in addition, the significant advantage that it positions the finger more toward the front, away from the trigger and whose form is designed in such a manner the finger is moved downward."16 Furthermore on the 2nd and 3rd of April 1900, the selection committee gathered once again in Bern to attend to the last details concerning the manufacturing and to address its final requests to the manufacturer (DWM). One of their requests was that: The shape of the trigger would be improved, following the specifications of the Federal weapon factory. On top of this, special tests were performed.17

As described by the Swiss, this description of the interim Swiss "design" and DWM implemented trigger fits the external profile (recognizable ergonomically redesigned pull surface) of the interim 1900 prototype trigger installed or "retrofitted" by DWM to some 1899 Borchardt-Lugers and final design 1900 production triggers. This Bern Archive (Bar) description does not fit the configuration of the 1899 "pre-production" triggers of Borchardt-Lugers 8 and 20. These triggers exhibit no evolutionary properties whatsoever, as described above by the Swiss Test Commission, over the original 1899 Borchardt-Luger thin side profile triggers; serial numbers 19, 22 and 40. In fact, the truncated circular integral pedestal for the spring, located in the partially enclosed circular recess of triggers 8 and 20 was a feature most certainly introduced by DWM with the interim prototype trigger and not by the Swiss. The original trigger spring retention configuration of the 1899 narrow trigger was obviously preferred by the Swiss as attested by the adoption of this feature for the new designed trigger for the Ordonnanzpistole 06/29 W + F.

A production DWM made 1900 trigger stamped serial number 22 is stated to be pictured in the 1900 Swiss Ordonnanzpistolen instruction manual fold-out drawing. This infers that it is part of an "upgrading kit" for 1899 Borchardt Luger serial number 22 discussed above. However, the trigger appears to be a DWM interim design prototype based on the lack of a taper on the lower ledge of the three-sided rectangular channel that accepts the side plate mounted lower section horizontal trigger lever arm.8 See below for more details of the interim trigger. Since 1899 Borchardt-Luger serial number 22 survives with the original thin trigger, no modifications to the frame trigger guard, original 5mm wide trigger spring location slot and also lacking the frame trigger guard chamfer relief cut, the presence of an "interim" trigger stamped 22 in the fold-out drawing is possible under the following scenario.

If the serial number 22 stamped interim prototype trigger that is shown in the 1900 Swiss Ordnance instruction manual illustration was fitted to 1899 Borchardt-Luger serial number 22, then this is the first documented evidence, albeit circumstantial, of the interim design prototype trigger being field tested by the Swiss in an 1899 Swiss Test/Acceptance Borchardt-Luger, namely 22. Why Borchardt-Luger serial number 22 ended up with the originally fitted 1899 narrow thin trigger is due partly because Borchardt-Luger 22 was never returned to the DWM tool room for retrofitting of the early 1900 design interim prototype trigger and modification of the frame trigger guard spring indent. Some of the 1899 Swiss Test/Acceptance Borchardt-Lugers were definitely returned to DWM for extensive modifications. The most notable modifications being the replacement of the square interface middle and rear link with the redesigned rounded interface links. In addition, the replacement of the original narrow thin profile trigger with the interim ergonomically designed prototype trigger, examples being serial numbers 23, 25, 26 and 30. Most significantly, these cited Borchardt-Lugers were additionally modified by the DWM tool room in the frame trigger guard area by widening the trigger spring indent from 5mm to 7mm to accommodate the interim new design trigger offset, examples being 23 and 30. The left and right side edge terminations of the center located 5mm wide trigger spring indent cut in the frame trigger guard of the unmodified 1899 Borchardt-Lugers are usually well defined. In the case of 1899 Borchardt-Luger serial number 20, the left side edge has been modified so as to be indiscernible.

Since Borchardt-Luger serial number 22 retains its frame trigger guard, center located 5mm wide trigger spring indent, this strongly suggests the interim trigger fitted to Borchardt-Luger 22 was one of the first tests of these interim prototype triggers. The triggers were supplied by DWM and installed by the Swiss for the continuing field tests. Most importantly, at the time of the field tests, the replacement trigger was the only modification of Borchardt-Luger 22 from its otherwise original configuration since the 1900 Swiss instruction manual illustration shows the original square interface toggle link assembly for Borchardt-Luger 22.

The continued field testing of Borchardt-Luger 22, beyond the March 1900 end of the special field tests, with the interim trigger most probably occurred prior to the more extensive modifications to serial numbers 23, 25, 26 and 30 as the Swiss were probably anxious to test, approve and accept the interim prototype trigger as the final trigger design, to be implemented by DWM, which coincidentally the later subsequent DWM tool room retrofitted Borchardt-Lugers were not returned to Switzerland but to other countries for evaluation, examples being 18, 23, 25, 26 and 30, appearing in Britain in approximately October/November 1900, leaving Borchardt-Luger 22 the only known documented example 1899 Swiss Test/Acceptance pistol, as of this writing, to be tested with two triggers.

This chronological description of events is supported by the special request of the last April 2, 1900 meeting of the Swiss Test Commission of the field test results of the 20 Swiss Test/Acceptance Borchardt-Lugers and subsequent final change requests to DWM, one specific request being as stated earlier: The shape of the trigger would be improved, following the specifications of the Federal weapon factory. On top of this, special tests were performed.17

The much later modification of Borchardt-Luger 22 to the 06/29 V series Luger, while retaining the rather obsolescent original narrow thin profile trigger and original frame trigger guard spring indent machining, errs more to the intended or eventual use of Borchardt-Luger 22 as a presentation or gift weapon rather than for experimentation or training purposes. This is also true of other similarly modified Borchardt-Lugers currently in the Eidgenössische Waffenfabrik collection.

Other than the external ergonomically redesigned pull surface of the interim and final 1900 production triggers, it is the internal or unseen features of the original 1899 trigger and the interim redesigned trigger that continue to "dog" the mechanics. Point one being the obvious regressive treatment of the trigger spring retention method on triggers 8 and 20 as described above, leaving two remaining subtle machining nuances. One which is common to both the 1899 trigger and the interim 1900 prototype trigger which is the slight step in the lower ledge of the three-sided rectangular channel that accepts the side plate mounted lower section horizontal trigger lever arm.

This step is identical in the original 1899 thin profile trigger and the 1900 DWM interim design production triggers

and is

missing in the final design 1900 production trigger, of which the step is replaced with a taper.

The serial number 22 early 1900 DWM interim prototype trigger in the M1900 Swiss Ordnance manual illustration shows the no taper trigger ledge.

The purpose of the change from a step to a taper is not documented but possibly to

aid in the insertion of the side plate mounted lower section horizontal trigger lever arm.

1899 Borchardt-Lugers identified with the interim trigger are serial numbers 23, 25, 26, 30

and 35. Borchardt-Luger 35 was personally inspected and the frame trigger guard recess examined with the interim design trigger removed. The center located 5mm wide trigger spring detent was widened by approximately 2mm, similar to Borchardt-Luger 23, to accommodate the offset new integral trigger spring pedestal guide.

The original 3-1/2 turn trigger spring was replaced, probably as part of the later V4 conversion, with a 7 turn tapered spring. The 3-1/2 turn spring had a 90 degree turned out tang that engaged a small drilled hole in the rear of the trigger. The hole is still present in the serial number 22 trigger. The tapered spring has a larger diameter at one end and smaller diameter at the other and more coils but still of small gauge wire. This equally weak replacement trigger spring still leaves the trigger with a light pull, but apparently, as stated by the Swiss, these replacement springs gave the trigger an "improved pull."18 Interestingly, in conjunction with the replacement trigger spring, some metal has been "shaved" off the higher stepped area, while still maintaining the step which can still be seen in profile, at the rear of the serial number 22 original trigger surrounding the trigger recess hole. The metal removal slightly extends the rearward pull of the trigger, flush to the rear trigger guard wall, resulting in a more positive engagement. This step is conspicuously absent in the Borchardt-Luger triggers 8 and 20.

The most probable original intent of the step was to engage the rear trigger guard wall with the maximum rearward pull of the trigger, allowing a small gap between the lower rear surface of the trigger and the rear frame trigger guard wall thereby eliminating the possibility of the trigger not returning to its full forward position after released by the finger, due to a possible build up of dirt or grease between the rear trigger surface and the frame rear trigger guard wall. A significant concern, considering the original 3-½ turn weak trigger return spring. This step was retained in all future DWM manufactured triggers.

A small section at the rear of the inside channel of the side plate of Borchardt-Luger 22 was relieved by rough grinding. This was part of the final trigger mechanism modification allowing a more positive trigger action by adding more clearance for the outward pivot movement of the rear section of the sear bar. This was achieved by extending the rearward motion of the trigger and with probable adjustments to the side plate bell crank or lever.

Comparing the 06/29 replacement sear-bar against a 1900 production Luger sear-bar shows essentially no dimensional differences. This suggests the modification to the side plate channel was relieved as stated above, being part of the modifications that included the trigger and replacement trigger spring, all to improve the smoothness and extend the range of action of the trigger operation.

The replacement trigger spring was no doubt changed by the W+K as other identical replacement springs have been noted on other production 1900 Swiss Ordnance Lugers. Two Swiss ordnance Luger examples are the old model sn 294 with unrelieved feedway and end of Swiss ordnance production old model, wide trigger sn 4993. The M1900 Swiss Ordnance Luger 294 production trigger was similarly modified as the serial number 22 (V4) to improve the trigger pull.

The DWM M1900/1906 Swiss Ordnance Luger triggers and the 06/24 Waffenfabrik Bern production triggers have a circular hole with an integral circular pedestal with a diameter that snugly accepts the smaller diameter tapered replacement spring. The other end of the spring is wider at 5.5 mm in diameter and seats in the M1900 Swiss ordnance sn 294 rear frame trigger guard 6mm wide cut-out frame detent. This keeps the trigger spring axially in position. The Swiss did not like the 1899 thin trigger early on and actually designed their own replacement trigger. The origins of the change to a stronger trigger return spring is less certain, however an excerpt from the Bern archives discussing the 1899-1900 test results errs toward a Swiss critique and subsequent DWM/Luger action: Testing commission member Colonel v. Mechel has observed experienced revolver marksmen who trembled with the pistol during somewhat more accelerated shooting. He thinks it is due to the fact that since they are used to the revolver, they did not advance the trigger forward enough after a shot and suggests to replace the, in his opinion, somewhat delicate trigger spring with a stronger one which gives the trigger a forward impulse.28 This request, one of several as a result of the March 1900 field test reports submitted by schools and shooting clubs, were submitted to Georg Luger who agreed to the modification proposals.

The trigger, redesigned and modified by the Swiss, defined by advanced collectors as the "interim design", technically “prototype” trigger, was fabricated in the DWM tool room and installed in some 1899 Swiss Test trials Borchardt-Lugers returned to DWM and sent on to England. These “interim triggers” other than their obvious physical differences from the original 1899 Borchardt-Luger thin, circular style triggers and special trigger springs, are virtually identical to the final 1900 production trigger, manufactured with production jigs with the exception of minor differences, with one particular, totally non-functional machining nuance described here, that can only be seen by viewing the interim trigger from the right side. The difference is in the angle of the stepped cut from the transition of the forward, narrower upper leading “push” section of the trigger to the lower, wider rear “pull” portion of the trigger, being a mere 15 degrees. Without access to an interim trigger and unless compared side-by-side against the final design 1900 production trigger, this subtly of machining would have never been detected. The identified interim 1899-1900 triggers fitted to 1899 Swiss Test Trial Borchardt-Lugers to date are: 23, 26, 30, and 35. Other 1899 Borchardt-Lugers identified with purported interim triggers are 25 of which no pictures are available. 1899 Borchardt-Lugers 10 (V1), xx (V12) currently in the Eidengössissche Waffenfabrik, Bern (W+F collection) also unfortunately, no pictures are available.

The Dutch Trials 1899 Borchardt-Luger 35 interim no serial number trigger suggests the currently configured, unnumbered BL35 frame is a DWM replacement, possibly already fitted with a new design unnumbered interim trigger, changed out in the DWM tool room after replacing the actual 35 numbered frame with its original 35 numbered narrow trigger, as originally submitted to the Dutch.29

The most interesting information discovered, regarding the interim trigger, is in relation to the much maligned 1899 Borchardt-Luger 33, with its well documented, questionable “interim” Toggle Link assembly, documented in three Luger book publications to date.30 Of all the existing pictures of 1899 Borchardt-Luger 33, which first appeared in the 1968 book Lugers at Random by C. Kenyon, and in later publications, to the current day, none show the right side of the pistol, which is needed to identify the trigger, whether interim or production. This issue was resolved in the most interesting manner. It seems that in the 1980s a VCR tape was made and publicly sold, titled: The Luger Pistol: A Video Profile, which included many Lugers from the collection of a world renowned Luger collector, which included 1899 Borchardt-Luger 33, rotating on a pedestal though 360 degrees of rotation, zooming in occasionally to show certain details, one of which was the trigger right side. A picture of the trigger was captured, after several attempts, by freezing the frame and taking a picture of the screen. The best effort picture, albeit poor quality, clearly identifies the trigger as not of the interim design, but of a 1900 production trigger. The 1900 production trigger in 1899 Borchardt-Luger 33, which is known to be stamped 33, further adds to other documented issues with 1899 Borchardt-Luger 33.

The Swiss did actually like certain design features of the 1899 narrow trigger, specifically the trigger spring circular recess hole, but without the internal, integral pedestal of the interim and final design production trigger. This feature, minus the integral pedestal was used for the trigger spring retention in the Swiss Model 06/29 production trigger along with, ironically a weaker trigger spring, not much stronger than the original, rejected 1899 Borchardt-Luger 3-½ turn trigger spring.

The frame trigger guard rear surface spring detent retention groove along with the left side frame trigger guard chamfer, common to all DWM Model 1900-1906 Lugers was not used in the Ordonnanzpistole 06/29 design, apparently both machining steps considered superfluous, the chamfer not necessary for inserting or removing the trigger or the groove for keeping the trigger and spring in position. The trigger retention hole was more than adequate in keeping the trigger axially in position.

Metal was also removed in the same area and manner on 1900 Swiss Ordonnanzpistole, serial number 294 production trigger as serial number 22, along with an identical replacement trigger spring. Additionally, the serial number 294 side plate original bell crank was replaced with an 06/29 Swiss inspection cross proofed bell crank. These changes were apparently also done to an early production Swiss Ordnance Luger, interestingly with an unrelieved frame with a flat follower button magazine, to effect a more positive trigger pull. 1900 Swiss Ordonnanzpistole, serial number 4993 wide trigger also has an identical replacement trigger spring which, as it turns out are Swiss 06/29 Ordonnanzpistolen production trigger springs. Both sns 294 and 4993 have Privatewaffen release dates of 1934 (P.34) and 1935 (P.35) respectively. This suggests the Swiss were experimenting with shooting accuracy in the late 1920’s and early 1930’s which, in this case, includes 1899 Borchardt-Luger serial number 22 (V4).

In addition to the BL22 and production trigger system modifications discussed above there are apparently many other similarly modified 1900 production Swiss Ordnance Lugers from the beginning and through the 1930s. An excerpt from the Bern archives, one of many on the trigger, gives an insight as to the thinking of the times regarding the trigger and shooting accuracy is presented:

"The trigger would become the frequent object of heated discussion in the coming years. It did not take long until eager marksmen began to change the trigger on their issue weapons in order to improve the point of impact.

On June 11, 1902 the Weapons Comptroller of the VIth Division, Major Burpbacher, sent the following letter to the administration of War materials:" 26

"I discovered by coincidence that the trigger of the automatic standard pistol for officers has been lightened up a little. This change was to have taken place on the catches, trigger rod, and firing pin. This is in all cases a dangerous operation which can result in tragic accidents. This is why very decisive measures have to be taken. Could not every officer in possession of this pistol be prohibited under penalty to make any changes in the mechanism of the pistol? Could not each pistol be subject to an annual control which would state and prevent such changes?

The weapon will also be used at events put on by shooting societies. Should there not be a carful, competent checking of the trigger prior to the event? I would like to inform you about this in hopes that this matter is serious enough to be considered." 27

The original components in Bochardt Luger serial number 22 retaining the original serial number 22 are:

- the receiver, 3mm in height on the bottom of the stop lug

- the left and right side original plain bordered grips, also 3mm in height and a smaller 1.5 mm in height number font on the component parts being

- the magazine release button on the right side

- the trigger

- the grip safety

- the hold-open device

- the Thumb Safety on the underside

- the take down lever on the right

- and the side plate underside.

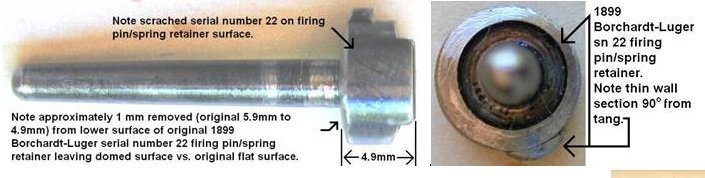

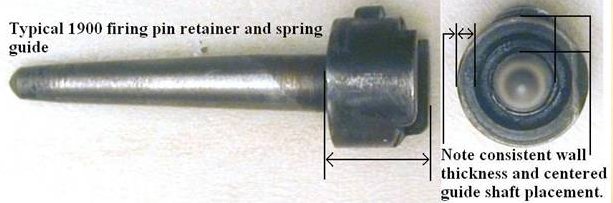

The toggle link assembly is the final design 06/29 Swiss proofed configuration. The rear link is marked V4 indicating the toggle link assembly’s possible experimental, prototype, training or presentation status. Curiously one part of the toggle link assembly is the original 1899 Borchardt-Luger serial number 22 firing pin retainer spring guide with the integral offset spring guide/retainer, identical to that used in Borchardt-Luger 5 and all 1899 preproduction prototype Borchardt-Lugers as illustrated in figures 8 and 9 of the original Borchardt-Luger instruction manual. The 1899 BL22 firing pin retainer is original except for an unusual modification, when compared against a 1900 production Luger firing pin retainer and additionally the serial number 22 is scratched on the retainer head outer circumference surface.

The serial number 22 firing spring guide/retainer modification is on the lower face of the circular head with integral tang on the outer circumference. The tang engages a corresponding slot inside the rear entrance to the breechblock. The tang is engaged by inserting the firing pin assembly and rotating the firing retainer head clockwise until engaging a recess detent. Metal was machined from the lower face of the 1899 firing pin retainer head, leaving the integral tang flush to the lower machined face as compared to the tangs original center position.

| |

1898 Borchardt-Luger serial number 5 firing pin retainer spring guide. | |

| |

1899 Borchardt-Luger serial number 22 firing pin retainer spring guide. | |

| |

1900 production Luger firing pin retainer spring guide. | |

The 1899 firing spring retainer guide shaft exhibits some white metal wear close to the head. The wear may be the remnants of being in a lathe to machine the lower face of the firing pin retainer head. Another possibly is that the wear occurred during firing from the constant shifting contact of the inner, tighter fitting, smaller diameter 1899 dual firing spring configuration against the larger diameter rear portion of the guide shaft.

The reason for this modification in relation to the 06/29 breechblock, of which the firing pin assembly retention method is mechanically identical to the 1899 breechblock, is not clear. The thought that comes to mind is that the modification to the 1899 serial number 22 firing pin retainer was done to address a problem in the original 1899 serial number 22 breechblock, probably encountered during the 1899/1900 Swiss Test/Acceptance trials. This is another example of the Swiss not wasting any part. More importantly, this suggests that prior to the Swiss conversion of serial number 22 to an 06/29 prototype, in 1929 at the earliest to as late as the 1940s, that 1899 Borchardt-Luger serial number 22 was in its original configuration as submitted to the Swiss in 1899 by DWM. There is the possibility that the original serial number 22 toggle link assembly, shown in the M1900 Swiss instruction manual still survives, hidden away in a drawer or box in the W+K collection.

The strawing of all the BL22 parts is original and upon disassembly two additional strawed parts were identified: the magazine button release flat spring and the narrow grip safety flat spring. Since these parts are heat tempered blue in the M1900 production Swiss Ordonnanzpistolen and all old model commercial Lugers, the first thought was that of an over zealous W + K Swiss gunsmiths' excess during the 1929 or later refurbishment to an 06/29 prototype. An examination of two other pictured 1899 narrow trigger Borchardt-Luger 06/29 V series prototypes20, namely serial numbers 10 (V1) and 28 (V6), show the exposed area of the magazine button release flat spring, of at first glance to be camera flash reflection, actually in retrospect, to be a strawed finish. With three 1899 Borchardt-Lugers showing strawed springs, all being refinished at the same time by the same technicians still errs toward post manufacture strawing.