Home page

Article created: Tuesday, June 19, 2007

Home page

Article created: Tuesday, June 19, 2007

|

Text Resize buttons |

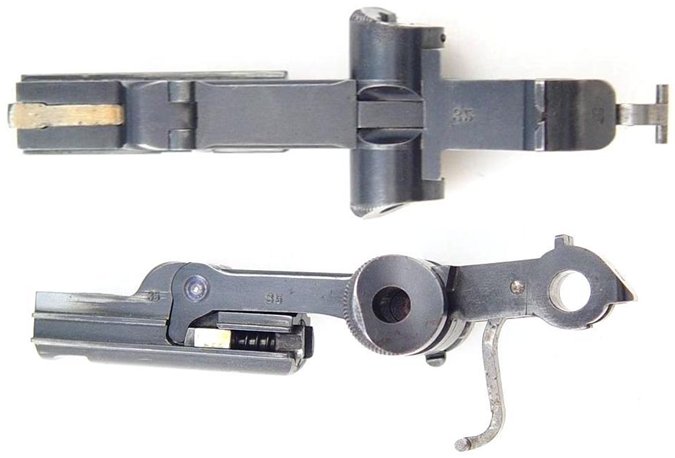

1899 Borchardt-Luger 351899 preproduction prototype Borchardt-Luger serial number 35 is fitted with an unserialized interim design production trigger. Delivered to the Dutch in March 1900, serial number 35 has been identified in two previous publications (The Dutch Luger and The Journal of the Historical Breechloading Smallarms Society) as a Dutch trials gun, and interestingly referred to a "production-style"7 trigger with the ergonomically redesigned pull surface. A detailed examination of the Borchardt-Luger 35 trigger revealed a slight step in the lower ledge top surface of the trigger slot that accepts the horizontal arm of the side plate lever. This slight step is common to both the 1899 original narrow, slab side triggers and the 1899/1900 interim prototype production triggers. The interim preproduction prototype status of the 35 trigger is also supported by other subtle machining differences that could not be mentioned here due to the proprietary nature of the information. Comparison of all three triggers (1899 original, 1900 interim and 1900 production) indicates an evolutionary progression of design. At first examination, the Borchardt-Luger 35 frame trigger guard spring detent appears to have been widened from its original 5 mm centered indent for the 3-½ turn, approximately 5 mm diameter trigger spring of the first installed original narrow, thin profile prototype trigger, to the approximately 1.25 mm right offset redesigned interim production trigger. Based on comparisons of the original centered 5 mm trigger spring detents of Borchardt-Lugers 22 and 40 against the expanded grooves of Borchardt-Lugers 23 and 30, the trigger spring indent of 35 was also widened to approximately 7 mm, about 2 mm on the right side of the original 5 mm centered indent to accommodate the 1.25 mm offset of the new trigger. Assuming the existence of an original 5 mm centered frame trigger guard spring detent in Borchardt-Luger 35, the expanded 7 mm interim width was established by the machinist by expanding the frame trigger guard centered 5 mm trigger spring indent right side border margin by approximately 2 mm, then machining out the detent or groove, although seeing the that entire 7 mm wide detent is white metal, suggesting the machining may have been a single operation and that there was no preexisting 5 mm centered groove. Since the widening of the BL35 frame trigger guard spring detent from 5 mm to 7 mm involved widening the right side of the existing groove only, means the left side of the groove was left undisturbed, or should have been left undisturbed, with the original 5mm width to the left side edge of the frame trigger guard maintained and should look like DWM tool room modified Borchardt-Lugers 23 and 30. However the very rough left side detent border of Borchardt-Luger 35 errs toward a hasty or rushed post manufacture, non DWM tool room modification. The unusually wide interim 7 mm frame trigger guard spring width detent suggests, possibly a slightly larger diameter trigger spring or larger wire diameter than the final 1900 production spring, of which a larger wire diameter would increase the stiffness of the new “interim” spring. The original weak 3-½ turn coil trigger spring used with the original narrow trigger is approximately 4-4.5 mm diameter with a wire diameter of 0.60 mm, The diameter of the spring is based on the 4.9 mm diameter of the completely enclosed narrow trigger spring hole. The final 1900 production spring diameter is 5 mm, but with a 5 turn coil spring and a larger wire diameter of 0.75 mm. The final frame trigger guard spring production detent width was reduced to 6 mm to accommodate the 5 mm diameter production trigger spring leaving a 1 mm clearance. However, given that the 1899 preproduction prototype serial number 35 frame and barrel with cut back receiver and added spacer lack a serial number, including the trigger, take down lever, side plate, wooden grips, magazine release button and the narrow grip safety, one could define the subject frame and barrel as not original to Borchardt-Luger 35 with certain machining peculiarities such as a post DWM tool room manufacture added 7 mm wide trigger spring recess indent, a frame lower thumb safety area without a polished bright upper periphery incised border and a “solid fill” forward gripstrap toe. The incomplete, non-serialized frame and barrel could, possibly have been field replacements, involving Luger himself, as he personally delivered Borchardt-Lugers 35 and 36 to the Dutch.24 With the exception of the Swiss V series conversions (which had their rear frame located serial numbers removed) all identified 1899 Borchardt-Luger preproduction prototype frames with BL40 being the highest serial number known above 35 and with several serial numbered examples below, all the small parts are serialized, so it is reasonable to assume that Borchardt-Luger 35 was originally manufactured with a serial numbered frame and small parts, possibly with an original narrow thin trigger. As to whether the original BL35 serialed configuration was delivered to the Dutch is pure speculation but the fact that the records show that BL35 was exposed to rather severe corrosive tests as admitted by the Dutch, suggests a possible frame replacement. Also when the BL35 frame trigger guard spring added, unblued indent or groove is compared against an unmodified 1899 Swiss Test/Acceptance frame trigger guard spring indent such as BL22 and 40, of which the detent or groove is blued, a reasonable conclusion would be that the original 5 mm frame trigger guard spring retention indents were machined prior to the frames being blued. Considering these facts it is possible that the “incomplete” serial number (35) frame was never fitted with the narrow thin trigger and in fact the frame was manufactured after the Swiss design and DWM manufacture of the interim production trigger or, alternately, was set aside for whatever reasons as an incomplete frame. Since Borchardt-Luger 40 survives with the square link interface toggle link assembly and the original narrow trigger, a reasonable assumption would be that all lower serial numbered 1899 Borchardt-Lugers were equally configured as originally manufactured, and that a completely serialized serial number 35 started out with a GL logo stamped, square link interface toggle link assembly (which it still retains) and the original narrow trigger (which it doesn’t.) If BL35 was delivered to the Dutch with a “redesigned standardized 1900 type” trigger as stated in the Dutch Luger Book25 then the original serialized 35 frame, fitted with the original narrow trigger was changed out by DWM, prior to delivery. Since there is no logical reason for such a switch, except the possibility that BL35 was extensively tested by DWM or parties unknown, prior to delivery to the Dutch, which is possible since the entire 1899 Borchardt-Luger Swiss test program was concluded by March 1900. Another possibility is that a replacement frame was provided to the Dutch, through Luger, with an improved interim production trigger. In support of the replacement status of the 35 frame, at the time of the March 1900 Dutch delivery of 1899 Borchardt-Lugers 35 and 36, certain Swiss trials guns had been returned from Switzerland to DWM, refitted with the interim prototype-production trigger and improved rounded interface toggle link assembly, and delivered to Britain for evaluation. With this in mind it is a difficult proposition to think that BL35 would be subsequently submitted to the Dutch in March 1900 with the interim production trigger, yet with the retro square link toggle link assembly. Modifications of the few 1899 Swiss Test/Acceptance field tested guns returned to the DWM tool room included fitting of the Swiss redesigned and DWM made interim production trigger and stronger spring, which involved widening of the frame rear trigger guard spring recess indent to accommodate the new trigger, which was certainly “spot” reblued in the widened area with the unmodified area of the recess retaining its original blue. The rather crude, possibly “field” machining of the 35 frame rear trigger guard recess for the trigger spring indent as compared to the very precise and exact tool room modifications, in the same area of 1899 Borchardt-Lugers serial numbers 23 and 30 as examples, further supports the later frame manufacture addition of the frame trigger guard spring recess. Interestingly, the tool room modification of serial numbers 23 and 30 the trigger spring recess cuts included the addition of the chamfer relief cuts, whereas serial number 35 lacks this machining operation. Certain other aspects of the serial number 35 frame are discussed in a British publication.7 Borchardt-Luger 35 is the only 1899 prototype frame identified that was fabricated without a trigger guard spring indent. However, it is not the only Luger frame manufactured without this feature. As late as 1906 early new model production there are rare instances of similar incomplete frames, one example being a 1906 early contract production navy Luger serial number 307. Serial number 307 is one of those rare instances of omission, not only of the spring recess indent but the absence of the left side frame chamfer, especially unusual since both the trigger guard spring recess indent or groove and the left side chamfer relief cut were part of the production drawings and additionally confirms that the trigger guard spring recess groove was a secondary machining operation. The absence of the mentioned secondary machining steps possibly explains the above claim of the Borchardt-Luger 35 frame being a replacement spare. Coincidently, both triggers of Borchardt-Luger 35 and 1906 navy Luger serial number 307 lack a serial number. In the case of 1906 navy Luger serial number 307 the rush to meet delivery schedule commitments and the new model machining difficulties are well documented and could conceivably account for the described omissions and other machining abnormalities not mentioned. Conversely, the lack of available 1899 Borchardt-Lugers (only a maximum of 40 fabricated with at least 20 going to the Swiss) to satisfy subsequent increased demand of foreign governments for submission of 1899 Borchardt-Lugers for evaluations and potential adoption in light of the Swiss military successes, in addition to the manufacturing time restraints could also, as stated above, account for the similar lack of minor, secondary machining steps and serial number omissions of the BL35 frame. A classic example being reworked, albeit improved, Swiss trials guns submitted to Britain rather than new pistols. The conceivable shortage of available 1899 Borchardt-Lugers in light of the heightened demand created problems for Luger and DWM and more than likely forced the fielding of limited, incomplete replacement parts inventory to keep test programs moving. Apparently substantial field failures or simple attrition were not anticipated, with the Borchardt-Luger 35 replacement frame being a prime example. None of the above critique is meant in any way to diminish the historical value or significance of 1899 Borchardt-Luger 35 and is merely an attempt to identify, explain or describe its unique characteristics. If anything, it further enhances its rare and distinctive position in the 1899 Borchardt-Luger preproduction prototype series.

Borchardt-Luger 35 toggle link assembly. |

Copyright © 2002-2008, Land of Borchardt, All rights reserved.