Jagdkarabiner “Parabellum”, Part Two - Presentation Carbines

1903 gold inlaid, chamber dated pre-production presentation Lugers 9109.C., 9111.C., 9112.C., 9116.C.

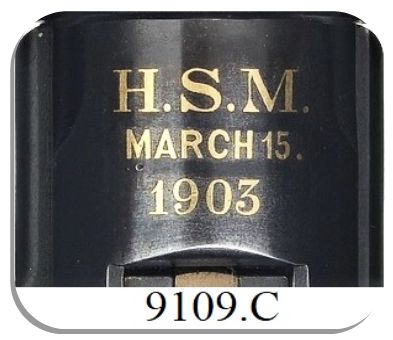

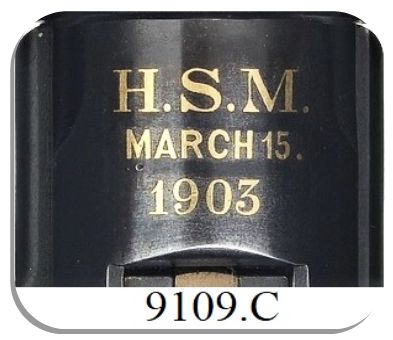

This article is mostly about GL pre-production presentation Luger carbine 9111.C. pre-production presentation Luger carbine 9111.C. , currently part of the Land of Borchardt , currently part of the Land of Borchardt Collection and three other 1903 gold inlaid, chamber dated Presentation Luger Carbines 9109.C Collection and three other 1903 gold inlaid, chamber dated Presentation Luger Carbines 9109.C ., 9112.C. ., 9112.C. , 9116.C , 9116.C . with 9109.C. being the most well-known, credited to Hiram S. Maxim as the recipient. There are other C-suffix presentation Luger carbines, however, the listed serial numbers were selected for comparison based on the 1903 chamber dates, with the probability of chronologically, more common features than differences. Although 9110.C . with 9109.C. being the most well-known, credited to Hiram S. Maxim as the recipient. There are other C-suffix presentation Luger carbines, however, the listed serial numbers were selected for comparison based on the 1903 chamber dates, with the probability of chronologically, more common features than differences. Although 9110.C . is not chamber dated, based on its serial number, it is in the mix. . is not chamber dated, based on its serial number, it is in the mix.

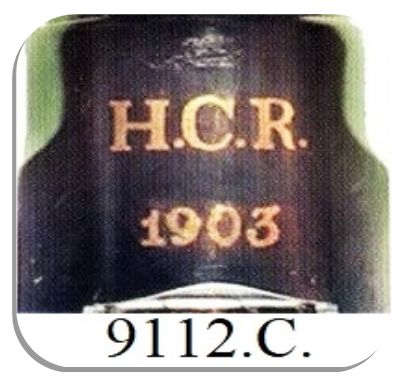

Since these special C-suffix presentation Luger carbines are assumed to be “presented” by Georg Luger to noted individuals, i.e. recipients such as Hiram S. Maxim and H.C.R., although it is not clear the relationship of Luger to H.C.R., another presentee or recipient, however, it is unusual that H.C.R. himself, based on the gold inlaid chamber markings of …FROM H.C.R. also has to be considered a presenter, who “presented” carbines to two other unknown personages or recipients, M.P.M. | FROM H.C.R. | 1903 (9111.C.) and J.L.M. | FROM H.C.R. | 1903 (9116.C.). and J.L.M. | FROM H.C.R. | 1903 (9116.C.). It is possible, assuming that H.C.R. was an American that Hans Tauscher, the United States DWM representative was somehow involved with the three known H.C.R. presentation Luger carbines. It is possible, assuming that H.C.R. was an American that Hans Tauscher, the United States DWM representative was somehow involved with the three known H.C.R. presentation Luger carbines.

The only scant information and pictures known about these presentation Luger carbines was gleaned from prior Luger books, other publications and auction descriptions. The only hands-on information available is the personal, detailed external and internal, closely examined features of presentation Luger carbine 9111.C. pictured in this article.

Unfortunately, the only information on 9112.C. is a sole picture of the gold inlaid H.C.R. | 1903![]() chamber stamping pictured in The Borchardt & Luger Automatic Pistols chamber stamping pictured in The Borchardt & Luger Automatic Pistols , a.k.a. TBLAP by †Görtz/Sturgess © 2010 & 2011, Volume 1, Chapter 3, page 246, Fig. 3-149. , a.k.a. TBLAP by †Görtz/Sturgess © 2010 & 2011, Volume 1, Chapter 3, page 246, Fig. 3-149. Although, while not referenced or noted at the time in TBLAP and the earlier © 2010 Pistole Parabellum publication Although, while not referenced or noted at the time in TBLAP and the earlier © 2010 Pistole Parabellum publication , a black and white picture of the top and left-side view of 9112.C. was pictured in the © 1969 Lugers At Random publication by †C. Kenyon, Jr. , a black and white picture of the top and left-side view of 9112.C. was pictured in the © 1969 Lugers At Random publication by †C. Kenyon, Jr. on page 81, on page 81, misidentified on the opposite page 80 description as 9113.C. misidentified on the opposite page 80 description as 9113.C. , which has never been identified. , which has never been identified.

The opposite page 80 Lugers at Random © 1969 General Notes description of 9112.C. additionally presents the first detailed, published description of the “machining” and most importantly, the machining “differences” of the first frame forging, knife-edge, push-button stock lugs and corresponding single-screw tang attaching irons interface: General Notes description of 9112.C. additionally presents the first detailed, published description of the “machining” and most importantly, the machining “differences” of the first frame forging, knife-edge, push-button stock lugs and corresponding single-screw tang attaching irons interface:

GENERAL NOTES: Manufactured by DWM under the personal supervision of Georg Luger, whose

hallmark, an intertwined GL appears on the back of the rear toggle link. The 1903 chamber dated, C-suffix presentation carbines have a unique stock lug of the type found on the Model 1900 Chilean carbines The 1903 chamber dated, C-suffix presentation carbines have a unique stock lug of the type found on the Model 1900 Chilean carbines and the presentation/prototype hunting carbines. Per †Kenyon this type of stock lug has a slight cam ramp and dwell in the right groove or channel of the lug and the presentation/prototype hunting carbines. Per †Kenyon this type of stock lug has a slight cam ramp and dwell in the right groove or channel of the lug . The “attaching iron” of the stock is machined accordingly and can NOT be fitted to a standard production stock lug, nor can a standard stock be fitted to the special lug of a presentation model (1900 or 1902). This example is inscribed H.C.R. | 1903 in GOLD INLAY above the chamber and is in very FACTORY NEW condition . The “attaching iron” of the stock is machined accordingly and can NOT be fitted to a standard production stock lug, nor can a standard stock be fitted to the special lug of a presentation model (1900 or 1902). This example is inscribed H.C.R. | 1903 in GOLD INLAY above the chamber and is in very FACTORY NEW condition . (Also, see General Notes on preceding page 80 . (Also, see General Notes on preceding page 80 .) .)

Per TBLAP, V1, C3, page 246 regarding the H.C.R. chamber stamping(s) states: Three known of the group, sns. 9111.C. (inscribed M.P.M. | FROM H.C.R. | 1903) Three known of the group, sns. 9111.C. (inscribed M.P.M. | FROM H.C.R. | 1903) ; 9112.C. (inscribed H.C.R.|1903) and 9116.C. J.L.M. | FROM H.C.R. | 1903) are linked to H.C.R., who has speculatively been identified as Henry C. Roan,[1] bookkeeper and partner of R.J. Reynolds in the eponymous tobacco company, but again, there is no evidence for this identification. ; 9112.C. (inscribed H.C.R.|1903) and 9116.C. J.L.M. | FROM H.C.R. | 1903) are linked to H.C.R., who has speculatively been identified as Henry C. Roan,[1] bookkeeper and partner of R.J. Reynolds in the eponymous tobacco company, but again, there is no evidence for this identification.

†Kenyon in the V44, #6 November 1998 Gun Report magazine, Lugers at Random column, again discusses the Presentation Carbine serial number range, including and describing 9102.C., 9103.C., 9106.C., 9109.C. and 9113.C. describing 9113.C., again misidentifying H.C.R. 1903 as 9113.C. when it should be 9112.C. †Kenyon specifically addresses the gold inlaid H.C.R. presentation carbines: Additional examples have been detail examined having gold inlay inscriptions †Kenyon specifically addresses the gold inlaid H.C.R. presentation carbines: Additional examples have been detail examined having gold inlay inscriptions being

being

- H.C.R. | 1903 (9112.C.)

, ,

- J.L.M. | FROMH.C.R. | 1903 (9116.C.)

, ,

- M.P.M. | FROMH.C.R. | 1903 (9111.C.)

and and

- J.P.G. | FROMH.C.R. | 1903 (91xx. C.)

---------------- page 2 ---------------

Number 4 being heretofore an unidentified by serial number presentation carbine. Note: There is no gold inlaid “TO” preceding text gold

inlaid chamber inscriptions.

9109.C. (inscribed H.S.M. | MARCH 15, | 1903

Rock Island Auction May 2019 Hiram S. Maxim Presentation Luger Carbine 9109.C. offering

EXTREMELY RARE AND WELL-DOCUMENTED HISTORIC "HIRAM MAXIM" PRESENTATION DWM MODEL 1902 LUGER CARBINE WITH GOLD INLAID CHAMBER FROM THE ICONIC RALPH SHATTUCK COLLECTION

Auction Date: May 4, 2019

Price Realized: $425,000

Estimated Price: $35,000 - $55,000

Description: This is a beautiful example of an original and very rare early production "Presentation Grade" DWM Model 1902 Luger carbine. This historic Luger carbine is from the personal collection of Ralph Shattuck and is pictured on pages 78 and 79 of the book "Lugers at Random", page 141 of " World of Lugers" by Costanzo This historic Luger carbine is from the personal collection of Ralph Shattuck and is pictured on pages 78 and 79 of the book "Lugers at Random", page 141 of " World of Lugers" by Costanzo and also in the book "Lugers of Ralph Shattuck" on page 16. and also in the book "Lugers of Ralph Shattuck" on page 16. This is a one-of-a-kind "Presentation Grade" Luger carbine manufactured by DWM for Hiram S. Maxim, the inventor of the Maxim machine gun. It is not a prototype nor one of the early transition Luger carbines, instead it has the rare early "special" serial number with the letter "C" suffix designation intended for special order Lugers manufactured as presentation pistols. The top of the chamber area is gold inlaid and reads: H.S.M. | MARCH 15, | 1903 This is a one-of-a-kind "Presentation Grade" Luger carbine manufactured by DWM for Hiram S. Maxim, the inventor of the Maxim machine gun. It is not a prototype nor one of the early transition Luger carbines, instead it has the rare early "special" serial number with the letter "C" suffix designation intended for special order Lugers manufactured as presentation pistols. The top of the chamber area is gold inlaid and reads: H.S.M. | MARCH 15, | 1903 . The DWM markings on the front toggle, the range markings on the rear sight and the intertwined GL initials of Georg Luger have also been highlighted with an old white colored highlighting material. Since this has the original intertwined GL initials on the rear toggle, Georg Luger most certainly supervised the actual production/manufacture of this Luger. It has all the early features such as an early flat breech bolt, dished toggles with toggle lock, grip safety and stock lug with an original DWM hold-open device. It is fitted with the 11¾-inch round, tapered barrel that is fitted with a ramp front sight base with a bead front sight and the classic "3-position" carbine rear sight. The top of the sight is marked "1, 2 and 3" for 100-300 meters. It has the original/correct hanger (tang) soldered[2] “on to the front of the frame”, correctly numbered 9109.C. on the underside. The last two-digits of the serial number (09) are stamped on the underside of the barrel, recoil lug, side plate, takedown lever, side of the breech bolt, and underside of the toggle train. It is fitted with matching checkered walnut grips that are numbered (“correctly” in pencil) on the back sides with "09". Since it is a carbine, it is fitted with the checkered walnut forend which is also numbered "09" on the inside and is correctly fitted with the small recoil accelerator inside. It is complete with an original tin-plated magazine with an unnumbered wooden base. This rare early carbine also comes complete with its correctly made “replacement” walnut stock with the early renumbered matching stock attaching iron. . The DWM markings on the front toggle, the range markings on the rear sight and the intertwined GL initials of Georg Luger have also been highlighted with an old white colored highlighting material. Since this has the original intertwined GL initials on the rear toggle, Georg Luger most certainly supervised the actual production/manufacture of this Luger. It has all the early features such as an early flat breech bolt, dished toggles with toggle lock, grip safety and stock lug with an original DWM hold-open device. It is fitted with the 11¾-inch round, tapered barrel that is fitted with a ramp front sight base with a bead front sight and the classic "3-position" carbine rear sight. The top of the sight is marked "1, 2 and 3" for 100-300 meters. It has the original/correct hanger (tang) soldered[2] “on to the front of the frame”, correctly numbered 9109.C. on the underside. The last two-digits of the serial number (09) are stamped on the underside of the barrel, recoil lug, side plate, takedown lever, side of the breech bolt, and underside of the toggle train. It is fitted with matching checkered walnut grips that are numbered (“correctly” in pencil) on the back sides with "09". Since it is a carbine, it is fitted with the checkered walnut forend which is also numbered "09" on the inside and is correctly fitted with the small recoil accelerator inside. It is complete with an original tin-plated magazine with an unnumbered wooden base. This rare early carbine also comes complete with its correctly made “replacement” walnut stock with the early renumbered matching stock attaching iron. This early attaching iron has the short upper and lower tang with a short, wide lever that is “identical[3]” to the early push-button attaching irons. The underside tang of the iron is matching numbered 9109. This early attaching iron has the short upper and lower tang with a short, wide lever that is “identical[3]” to the early push-button attaching irons. The underside tang of the iron is matching numbered 9109. The stock and forend have beautiful hand checkered panels on the sides. It has a rust blued metal finish with straw-colored smaller parts. The stock and forend have beautiful hand checkered panels on the sides. It has a rust blued metal finish with straw-colored smaller parts.

Short upper and lower single-screw tang, turn-lever hunting carbine attaching iron

A brief discussion is necessary regarding the single-screw tang, turn-lever attaching iron, first pattern Luger hunting carbine wooden stock prior to discussing the 9109.C. hunting carbine stock. Sturgess describes these stocks, identical to 9109.C. in the following manner in TBLAP, Chapter 3, page 256 titled: Production Carbines. Certain statements are highlighted and extracted, being specific to the subject and are: The first batch of production carbines produced for commercial sales bore serial numbers in the 21xxx range… The frame machining in the stock fitting area at the base of the rear gripstrap was now based on the final production pattern forging, with greater thickness of metal resulting in a distinct flat about 1 mm wide between the rear edge of the magazine wall and the rear external contour of the grip strap, rather than the near knife-edge of earlier stocked guns… The early stock fitting for the carbines in the low 21xxx serial range was still, however, of the single-screw pattern. Sturgess describes these stocks, identical to 9109.C. in the following manner in TBLAP, Chapter 3, page 256 titled: Production Carbines. Certain statements are highlighted and extracted, being specific to the subject and are: The first batch of production carbines produced for commercial sales bore serial numbers in the 21xxx range… The frame machining in the stock fitting area at the base of the rear gripstrap was now based on the final production pattern forging, with greater thickness of metal resulting in a distinct flat about 1 mm wide between the rear edge of the magazine wall and the rear external contour of the grip strap, rather than the near knife-edge of earlier stocked guns… The early stock fitting for the carbines in the low 21xxx serial range was still, however, of the single-screw pattern. This conflicts with the †Kenyon opinion expressed in the © 1969 Lugers at Random This conflicts with the †Kenyon opinion expressed in the © 1969 Lugers at Random on page 80 in General Notes describing the opposite page 81 picture of H.C.R 1903, serial number 9112.C. presentation carbine with unmodified, original first frame forging, knife-edge, push-button stock lug states that: The (single-screw tang, push-button) “attaching iron” of the stock is machined accordingly and can NOT be fitted to a standard production (final forging) stock lug, nor (conversely) can a standard, (two-screw, turn-lever) stock be fitted to the special (first forging, knife-edge) lug of a presentation model. on page 80 in General Notes describing the opposite page 81 picture of H.C.R 1903, serial number 9112.C. presentation carbine with unmodified, original first frame forging, knife-edge, push-button stock lug states that: The (single-screw tang, push-button) “attaching iron” of the stock is machined accordingly and can NOT be fitted to a standard production (final forging) stock lug, nor (conversely) can a standard, (two-screw, turn-lever) stock be fitted to the special (first forging, knife-edge) lug of a presentation model.

---------------- page 3 ---------------

Then, there are always exceptions to the †Kenyon rule as with the early 21300 final frame forging production series carbines as Sturgess states in TBLAP, V1, C3, page 256, that some of these early, first batch production carbines were fitted with spare, interim single-screw tang, turn-lever hunting carbine stocks were fitted to final frame forging production Luger carbines, examples being 21446 that some of these early, first batch production carbines were fitted with spare, interim single-screw tang, turn-lever hunting carbine stocks were fitted to final frame forging production Luger carbines, examples being 21446 , 21620 , 21620 , 21644 , 21644 , 21663 , 21663 and 21671 which, no doubt by DWM, prior to sale required modification of the attaching iron and stock lug. and 21671 which, no doubt by DWM, prior to sale required modification of the attaching iron and stock lug. Another example of an exception to the †Kenyon rule is the opposite mating situation, also described by †Kenyon, in this case, of a two-screw, production dimensioned attaching iron mated to a Chilean carbine 10008 with a first frame forging, knife-edge stock lug, modified to a turn-lever, ironically mated to a bizarre two-screw tang, push-button attaching iron, additionally with an unusual shaped hunting carbine wooden stock. Another example of an exception to the †Kenyon rule is the opposite mating situation, also described by †Kenyon, in this case, of a two-screw, production dimensioned attaching iron mated to a Chilean carbine 10008 with a first frame forging, knife-edge stock lug, modified to a turn-lever, ironically mated to a bizarre two-screw tang, push-button attaching iron, additionally with an unusual shaped hunting carbine wooden stock.

“THE GUN REPORT” V42, #9, Feb 1997 monthly Lugers at Random Q&A section †Kenyon describes the stocks of the early 1900 carbines and 175 m/m barrel examples as: The first series of 1902 carbines (21000 – 22100) utilizes a stock with a small “wrist” and a turn lever “attaching iron” also with a short tang and single screw attachment. This implies that the first 1,000 production carbines sport hunting carbine stocks with the single-screw tang, turn-lever attaching iron. Again, there are not enough examples identified in this range to support 1,000 production hunting carbines with the interim single-screw, turn-lever attaching iron stocks.

Interestingly, †Kenyon in the Feb 1997 Gun Report magazine Q&A section makes the curious closing remark being: For some reason collectors seem to find the single-screw stocks more desirable. Possibly in the 1990s that was the general consensus due to a lack of information, however, in the last 20 years or so, with much more new information discovered on the single-screw tang, push-button and turn-lever attaching iron hunting carbine stocks, finds that the reason for collector interest becomes abundantly clear, in that that they are exclusively associated with the extremely rare, small batch; Possibly in the 1990s that was the general consensus due to a lack of information, however, in the last 20 years or so, with much more new information discovered on the single-screw tang, push-button and turn-lever attaching iron hunting carbine stocks, finds that the reason for collector interest becomes abundantly clear, in that that they are exclusively associated with the extremely rare, small batch;

- early pre-production two-digit serial numbered hunting carbines with 1-3-5 adjustable tangent rear sights

and, and,

- presentation 9100. C series Luger hunting carbines,

and, and,

- to a lesser extent, some five-digit 21100 production serial number series hunting carbines,

all three variations with first frame forging knife edge push-button stock lugs, elevates them to the top tier of Luger rarities and exceedingly rare if they are part of matching rigs. all three variations with first frame forging knife edge push-button stock lugs, elevates them to the top tier of Luger rarities and exceedingly rare if they are part of matching rigs.

Regarding the early 21000 production Luger carbines with matching, three-digit serialized, second or final pattern production two-screw tang, push-button attaching iron hunting carbine stocks starting at approximately 21300 to 21700. In this range, Luger production carbines, mostly with mating, three-digit serialized, final pattern, two-screw, turn-lever attaching iron hunting carbine stocks are sprinkled with mating, pre-production, three-digit serialized, first pattern, single-screw tang, turn-lever attaching iron hunting carbine stocks as noted in the previous paragraph and the accompanying data base with red asterisks next to the serial numbers.

One can assume, as a rule of thumb, that of the five identified, represent about ten percent of the total or about fifty “mix and match” production carbines with pre-production first-pattern hunting carbine stocks. Interestingly, this suggests many more first-pattern, single-screw tang, turn-lever attaching iron hunting carbine stocks were made than expected. This is somewhat supported by Sturgess in TBLAP, V1 C3 page 257 where he states that: …seemingly all of the 23xxx and 24xxx blocks above approximately sn 23400 being standard production carbines with the later twin screw stock fitting. The statement seems to imply that all/most production Luger carbines below serial number 23400 sport the pre-production, first-pattern, single-screw tang, turn-lever attaching iron hunting carbine stocks. The statement seems to imply that all/most production Luger carbines below serial number 23400 sport the pre-production, first-pattern, single-screw tang, turn-lever attaching iron hunting carbine stocks.

However, the above TBLAP V1, C3, page 256 statement that hunting carbines below 21400 sport the pre-production, first-pattern, single-screw tang, turn-lever attaching iron hunting carbine stocks is not supportable as the carbines identified in this article with these features are in the 21600 serial number range, and in addition to the pre-production, first-pattern, single-screw tang, turn-lever attaching iron hunting carbine stocks are affixed not to final frame forgings, but to first frame (Chilean) forgings with knife-edge push-button stock lugs. Pictured as an example is hunting carbine 21644 which clearly shows in a bottom view of the single screw tang, turn-lever attaching iron affixed to a first frame forging, knife edge stock lug stock lug interface. which clearly shows in a bottom view of the single screw tang, turn-lever attaching iron affixed to a first frame forging, knife edge stock lug stock lug interface.

Per an LOB data base of identified production Luger carbine serial numbers, the highest serial number identified is 24906, therefore, according to Sturgess, based on only 1506 (24906-23400) Luger carbines that are mated/fitted with the final production pattern, two-screw tang, turn-lever hunting carbine stock. With a total estimated production of approximately 2500 production carbines leaves 2500 minus 1506 or 904 production, first frame forging Luger carbines mated/fitted with pre-production, first-pattern, single-screw tang attaching iron hunting carbine stocks. The low number of identified production Luger carbines with three-digit serial number stamped matching, identified first pattern, single-screw tang, turn-lever attaching iron hunting carbine stocks data base of identified production Luger carbine serial numbers, the highest serial number identified is 24906, therefore, according to Sturgess, based on only 1506 (24906-23400) Luger carbines that are mated/fitted with the final production pattern, two-screw tang, turn-lever hunting carbine stock. With a total estimated production of approximately 2500 production carbines leaves 2500 minus 1506 or 904 production, first frame forging Luger carbines mated/fitted with pre-production, first-pattern, single-screw tang attaching iron hunting carbine stocks. The low number of identified production Luger carbines with three-digit serial number stamped matching, identified first pattern, single-screw tang, turn-lever attaching iron hunting carbine stocks does not support the TBLAP V1 C3 page 257 Sturgess conclusions. does not support the TBLAP V1 C3 page 257 Sturgess conclusions.

The four-digit C-suffix serial number Presentation Carbines

When observing the C-suffix presentation carbines with their first pattern hunting carbine stocks attached, it appears that the eight identified pre-production presentation carbines

9102.C. ,

9103.C ,

9103.C .,

9106.C .,

9106.C .,

9109.C .,

9109.C .,

9110.C .,

9110.C .,

9111.C .,

9111.C .,

9112.C .,

9112.C . and

9116.C . and

9116.C ., that all except

9102.C. ., that all except

9102.C. ,

9106.C. ,

9106.C. and

9109.C. and

9109.C. sport the first, single-screw tang, push-button attaching iron, first-pattern hunting carbine stocks, sport the first, single-screw tang, push-button attaching iron, first-pattern hunting carbine stocks, despite their stock lugs being modified to accept the first pattern, single-screw tang, turn-lever attaching iron hunting carbine stock. despite their stock lugs being modified to accept the first pattern, single-screw tang, turn-lever attaching iron hunting carbine stock. It should be noted that while there is no identified hunting carbine stock for 9112.C. It should be noted that while there is no identified hunting carbine stock for 9112.C. [4], it appears that its’ push-button stock lug has not been modified to accept a turn-lever hunting carbine stock. As for 9116.C. [4], it appears that its’ push-button stock lug has not been modified to accept a turn-lever hunting carbine stock. As for 9116.C. with its production two-screw, turn-lever attaching iron hunting carbine stock, appears to be mated with a final frame forging production carbine. with its production two-screw, turn-lever attaching iron hunting carbine stock, appears to be mated with a final frame forging production carbine.

---------------- page 4 ---------------

Pictured is a table compilation of the known C-suffix pre-production presentation Luger carbines and their hunting carbine stocks. Note that a block of serial numbers, as suggested, were probably not set aside for the C-suffix pre-production presentation carbines and that the gaps may not be missing presentation carbines and are, more than likely, 1900 American Eagle Lugers based on the 9115 serial number American Eagle Luger offered by Simpson Ltd in 2016. Ergo, some of the numbers used in that block (range) for the presentation carbines were assigned by DWM to noted personages or by customer request. Note that a block of serial numbers, as suggested, were probably not set aside for the C-suffix pre-production presentation carbines and that the gaps may not be missing presentation carbines and are, more than likely, 1900 American Eagle Lugers based on the 9115 serial number American Eagle Luger offered by Simpson Ltd in 2016. Ergo, some of the numbers used in that block (range) for the presentation carbines were assigned by DWM to noted personages or by customer request.

That leaves the H.S.M. March, 1903 gold inlaid chamber marked 9109.C. presentation carbine, gold inlaid chamber marked 9109.C. presentation carbine, one of two identified C-suffix presentation carbines out of eight with the second, interim, single-screw tang, turn-lever attaching iron hunting carbine stock. Combined with the fact that 9109.C. first appeared in the March 1967 GUNS magazine, one of two identified C-suffix presentation carbines out of eight with the second, interim, single-screw tang, turn-lever attaching iron hunting carbine stock. Combined with the fact that 9109.C. first appeared in the March 1967 GUNS magazine, next in the © 1969 Lugers at Random next in the © 1969 Lugers at Random publication on page 79 and in the © 1977 World of Lugers publication on page 141 publication on page 79 and in the © 1977 World of Lugers publication on page 141 , both pictured without a stock. The March 1967 Guns magazine has an article by †Shattuck describing and picturing his 9109.C., Hiram S. Maxim presentation carbine on the cover. , both pictured without a stock. The March 1967 Guns magazine has an article by †Shattuck describing and picturing his 9109.C., Hiram S. Maxim presentation carbine on the cover. The H.S.M. carbine is featured on the cover and on pages 18 and 19 with a caption stating: The author’s Presentation Carbine, together with its accompanying stock, is in virtually mint condition. The H.S.M. carbine is featured on the cover and on pages 18 and 19 with a caption stating: The author’s Presentation Carbine, together with its accompanying stock, is in virtually mint condition. The left-side of The left-side of the a carbine and stock are pictured in black and white on page 20, pictured for comparison with the RIA 2015 auction identical left-side view and with a typical circa 1904 production carbine. Note the similar appearance of the striations or grain pattern/direction of the 1967 pictured hunting carbine stock and the production example vs the 2015 purportedly identical left-side color version.

The differences in appearance in the wood grain striation patterns in combination with some comparative dimensions of the distance from the bottom of the grip safety to the top of the attaching iron of the 1967 black and white production carbine and the color production example are identical being 9 mm in length, whereas the 2015 RIA picture of 9109.C., the distance is 14 mm, a difference of 5 mm which is the exact difference in the 35 mm height of the single screw, push-button, turn-lever Luger hunting carbine stock attaching irons vs the 40 mm height of the two-screw, turn-lever production Luger hunting carbine stock attaching iron.

In summary, the 1967 GUNS magazine, page 20 pictures are of two unidentified production carbines, one with and one without a stock and that neither are presentation carbine 9109.C., but of two unknown production Luger carbines, one fitted with an unidentified production Luger hunting carbine stock. It would be only speculation or conjecture as to why the 1967 GUNS magazine article by †Ralph Shattuck did not picture the mating stock with 9109.C., however, it is not speculation to therefore conclude that the current, single-screw tang, turn-lever Luger hunting carbine 9109 attaching iron numbered stock may not be original to 9109.C. and that it is possible that the original stock fitted to 9109.C. was a single-screw tang, push-button hunting carbine stock, which is not an unreasonable assumption seeing that the four of the eight C-suffix, first forging, knife-edge push-button stock lug frames with corresponding attaching iron presentation carbines pictured and discussed in this article sport a single-screw tang, push-button hunting carbine stock. There is the remote possibility that when the March 1967 GUNS magazine It would be only speculation or conjecture as to why the 1967 GUNS magazine article by †Ralph Shattuck did not picture the mating stock with 9109.C., however, it is not speculation to therefore conclude that the current, single-screw tang, turn-lever Luger hunting carbine 9109 attaching iron numbered stock may not be original to 9109.C. and that it is possible that the original stock fitted to 9109.C. was a single-screw tang, push-button hunting carbine stock, which is not an unreasonable assumption seeing that the four of the eight C-suffix, first forging, knife-edge push-button stock lug frames with corresponding attaching iron presentation carbines pictured and discussed in this article sport a single-screw tang, push-button hunting carbine stock. There is the remote possibility that when the March 1967 GUNS magazine article was written, for unknown reasons the original stock for 9109.C. was not available. In summary, the 1967 Guns magazine article on Presentation Luger Carbine 9109.C. was mostly promotional in nature and content, providing little information. article was written, for unknown reasons the original stock for 9109.C. was not available. In summary, the 1967 Guns magazine article on Presentation Luger Carbine 9109.C. was mostly promotional in nature and content, providing little information.

The low budget booklet published in 2000 titled: The Lugers of †Ralph Shattuck again featured his 9109.C. presentation carbine on page 16 using a color photograph of 9109.C. with a correct single-screw tang, attaching iron, however, despite the Luger hunting carbine stock resembling the RIA 2015 auction picture, albeit of a poor quality resolution, though with enough detail to determine 9109.C. was affixed with a single-screw tang, attaching iron Luger production hunting carbine stock. However, the photograph, while picturing the left-side of the carbine and stock, yet somehow in addition to misspelling “Maxim” (Maxim) several times in the text description also managed to additionally butcher the picture, showing the left-side view of 9109.C. and stock while somehow managing to show the attaching iron opposite right-side spindle end (circled) leaving unknown if the pictured stock is indeed correct. Pictured is an enhanced picture of the 2000 publication Lugers of Ralph Shattuck serial number 9109 left-side hunting carbine stock compared with the 2019 RIA auction picture of same. Pictured is an enhanced picture of the 2000 publication Lugers of Ralph Shattuck serial number 9109 left-side hunting carbine stock compared with the 2019 RIA auction picture of same.

Two close-up pictures of the first frame forging, knife-edge, push-button stock lug of 9109.C. clearly shows the intact reattached rear, turn-lever section of the stock lug showing the (1) reattached upper stock lug interface seam and the (2) upper, one of two, flush mount rivets. Pictured are several views labeled 1), 2) and 3) showing the deterioration of the reattached stock lug of the first frame forging, knife-edge, push-button stock lug of 9109.C. through the years 1967 – 2019. Pictured are several views labeled 1), 2) and 3) showing the deterioration of the reattached stock lug of the first frame forging, knife-edge, push-button stock lug of 9109.C. through the years 1967 – 2019. Note the final 2019 Rock Island Auction picture numbered 3) with the reattached portion of the push-button/turn-lever stock lug totally missing, exposing the upper and lower gripstrap securing pan-head rivets and shafts Note the final 2019 Rock Island Auction picture numbered 3) with the reattached portion of the push-button/turn-lever stock lug totally missing, exposing the upper and lower gripstrap securing pan-head rivets and shafts . .

9109.C. Auction Description Reviewed

The Hiram S. Maxim auction description is the most well-known of the C-suffix serial numbered 1903 chamber dated Presentation Luger Carbines. The auction description states that the attaching iron is of the early type, described by †Görtz/Sturgess in TBLAP as used with the first frame forging with knife-edge push-button stock lugs, apparently modified to accept the second pattern, interim design hunting carbine stock with single screw, turn-lever type attaching iron. as used with the first frame forging with knife-edge push-button stock lugs, apparently modified to accept the second pattern, interim design hunting carbine stock with single screw, turn-lever type attaching iron.

The auction description also states that the accompanying, “ correctly made replacement walnut stock” correctly made replacement walnut stock” second pattern, interim design hunting carbine stock with single-screw tang, turn-lever type attaching iron, that the attaching iron has been “renumbered” second pattern, interim design hunting carbine stock with single-screw tang, turn-lever type attaching iron, that the attaching iron has been “renumbered” to match the carbine forestock tang 9109.C. serial number stamping. The statement that the single-screw tang, turn-lever hunting carbine stock has been “renumbered” to “match” the Hiram S. Maxim carbine creates issues: to match the carbine forestock tang 9109.C. serial number stamping. The statement that the single-screw tang, turn-lever hunting carbine stock has been “renumbered” to “match” the Hiram S. Maxim carbine creates issues:

- was 9109.C. originally assembled with the first design, single-screw tang, push-button attaching iron hunting carbine wooden stock and was it numbered?,

- with RIA stating that the lower tang of the single-screw tang, turn-lever attaching iron was “renumbered” additionally implies or suggests that a number was removed, requiring the area to be reblued, prior to, or after adding 9109, yet there is no evidence to support the “renumbered” claim,

- since Sturgess states that the first frame forgings with knife-edge push-button stock lugs were used for this series of Presentation Carbines, of which the stock lugs were purportedly (all) converted to accept the second design, single screw attaching iron turn-lever hunting carbine wooden stock

at the time of assembly and that the bottom tang of the attaching iron of the current stock was stamped 9109 at that time. at the time of assembly and that the bottom tang of the attaching iron of the current stock was stamped 9109 at that time.

---------------- page 5 ---------------

It is well-known or established that the very early, two-digit circa 1901 prototype/production Luger carbines were mated exclusively with the first-pattern, single-screw tang, push-button attaching iron hunting carbine wooden stocks [5] it is, therefore, odd regarding the above scenario with 9109.C., as why change out a perfectly good, functioning first issue, single-screw tang, push-button attaching iron hunting carbine wooden stock. [5] it is, therefore, odd regarding the above scenario with 9109.C., as why change out a perfectly good, functioning first issue, single-screw tang, push-button attaching iron hunting carbine wooden stock.

Part of the answer may rest with the configuration of the first forging, knife-edge frames used for these C-suffix presentation carbines, as to whether they were originally fitted with the forestock tang or added, and if the second pattern, interim design single-screw tang, turn-lever attaching iron, Luger hunting carbine wooden stock, at the time, had already superseded the now, short-lived, obsolete first design, single-screw tang, push-button attaching iron Luger hunting carbine wooden stock, which was available at the time of assembly of these C-suffix, four-digit serial number presentation carbines. If the interim, second pattern design, turn-lever Luger hunting carbine wooden stock was available, which was available at the time of assembly of these C-suffix, four-digit serial number presentation carbines. If the interim, second pattern design, turn-lever Luger hunting carbine wooden stock was available, the first frame forging, knife-edge stock lug was, therefore, modified at original assembly to accept the interim second pattern design with the single-screw tang, turn-lever attaching iron, numbered at the time of assembly. the first frame forging, knife-edge stock lug was, therefore, modified at original assembly to accept the interim second pattern design with the single-screw tang, turn-lever attaching iron, numbered at the time of assembly.

The problem with the above scenario is that the auction description specifically states that the accompanying Hiram S. Maxim presentation hunting carbine stock, single-screw tang, turn-lever attaching iron has been “renumbered” to “match” the forestock tang of the Maxim Carbine. This wouldn’t be necessary if the stock was original to the carbine. Also complicating is the fact that the rear gripstrap, knife-edge stock lug of 9109.C. was purportedly, removed early on as part of a 1934 federal regulation regarding stock lugs and it is uncertain that the poorly reattached, removed portion of the stock lug is original to 9109.C. or later installed from part of a production turn-lever stock lug. and it is uncertain that the poorly reattached, removed portion of the stock lug is original to 9109.C. or later installed from part of a production turn-lever stock lug.

Additionally, it is certain that the C-suffix, first frame forgings with integral knife-edge push-button stock lugs needed additional machining to correctly fit a single-screw tang, push-button attaching iron. Specifically, it appears that a secondary machining step, not part of the first frame forgings, was required to the right-side attaching iron upper top portion of the guide channel as described by †Kenyon in Lugers at Random : This type of (push-button) stock lug has a slight cam ramp and dwell (detent) in the right groove of the lug to accommodate the attaching iron, spring loaded push-button locking arm. Pictured is a typical close-up view of a correctly milled push-button slot detent in the upper portion of the right-side stock lug curved channel. Note the smooth, recessed milled surface, void of any machining marks. : This type of (push-button) stock lug has a slight cam ramp and dwell (detent) in the right groove of the lug to accommodate the attaching iron, spring loaded push-button locking arm. Pictured is a typical close-up view of a correctly milled push-button slot detent in the upper portion of the right-side stock lug curved channel. Note the smooth, recessed milled surface, void of any machining marks.

Since it is certain the original frame forgings lacked this very small 2 mm wide x 6mm length dimensioned sloped detent , it was obviously added, being a secondary milling operation, , it was obviously added, being a secondary milling operation, which suggests that these C-suffix first forging frames used, were deliberately intended for use with the single-screw tang, push-button attaching hunting carbine stocks which suggests that these C-suffix first forging frames used, were deliberately intended for use with the single-screw tang, push-button attaching hunting carbine stocks and not the single-screw tang, turn lever attaching iron hunting carbine stocks, and not the single-screw tang, turn lever attaching iron hunting carbine stocks, which would not have required the secondary, push-button detent machining step. To further iterate on the secondary machining scenario, the C-suffix turn-lever modified first frame forging knife-edge stock lugs would lack the secondary, push-button required machining, yet four of the eight C-suffix presentation carbines identified in this article are fitted with the single-screw tang, push-button hunting carbine stocks. which would not have required the secondary, push-button detent machining step. To further iterate on the secondary machining scenario, the C-suffix turn-lever modified first frame forging knife-edge stock lugs would lack the secondary, push-button required machining, yet four of the eight C-suffix presentation carbines identified in this article are fitted with the single-screw tang, push-button hunting carbine stocks.

Furthermore, it is a general misunderstanding that by simply adding a dish or scoop to the rear surface of a push-button stock lug to accept a one or two-screw, turn-lever type attaching iron that both variations of the stock lug, the push-button and the turn-lever are interchangeable, they are not, and not because of the, albeit minor differences of the stock lugs. It is the hunting carbine attaching irons that are different with the one vs. two-screw versions being dimensionally different with the two-screw production attaching iron, specifically the height being larger or taller by 5 mm , compounded by the curved design of the interface, which creates a binding issue when attempting to fully insert/attach a two-screw attaching iron to a first frame forging, knife-edge stock lug. , compounded by the curved design of the interface, which creates a binding issue when attempting to fully insert/attach a two-screw attaching iron to a first frame forging, knife-edge stock lug. This is addressed in general terms by †Kenyon in Lugers at Random This is addressed in general terms by †Kenyon in Lugers at Random on page 80 General Notes, however, without any specific details. on page 80 General Notes, however, without any specific details.

The ill-fitting of the second pattern, single-screw tang, turn-lever, “renumbered to match” attaching iron Luger hunting carbine stock to the Hiram S. Maxim 9109.C. presentation carbine rear gripstrap, knife-edge, push-button stock lug is clearly noticeable on the Rock Island Auction provided view of the right-side carbine and stock compared against the © 2000, page 16, Lugers of Ralph Shattuck publication picture of 9109.C. Pictured is a close-up the RIA auction photo of the, in-profile right-side, rear gripstrap of 9109.C. stock lug compared against unmodified 10005 combination push-button/turn lever stock lug Pictured is a close-up the RIA auction photo of the, in-profile right-side, rear gripstrap of 9109.C. stock lug compared against unmodified 10005 combination push-button/turn lever stock lug and a three-view stock lug picture of 9109.C. taken in 2015 while in Las Vegas prior to its first auction. and a three-view stock lug picture of 9109.C. taken in 2015 while in Las Vegas prior to its first auction.

When comparing the “renumbered to match” 9109 attaching iron one can clearly see that a different stamping method of application is evident as compared to other pictured presentation carbine forestock tang stampings using 9116.C. tang stamping as an example and to other second design, single screw, turn-lever attaching iron stampings. It would be interesting to see the 9109.C. forestock tang stamping for comparison, and to other second design, single screw, turn-lever attaching iron stampings. It would be interesting to see the 9109.C. forestock tang stamping for comparison, i.e., similarity of stampings, unfortunately, it is not available. i.e., similarity of stampings, unfortunately, it is not available.

A partial top view of the lesser known, C-suffix pre-production Presentation Luger Carbine 9111.C. is first pictured in the ©1991 publication Luger: The Multi-National Pistol a.k.a. LTMNP by †C. Kenyon, Jr. on page 64. a.k.a. LTMNP by †C. Kenyon, Jr. on page 64. It is interesting that in the page 64 text information, †Kenyon states a range of 9101.C. – 9110.C., yet pictures a partial top view of 9111.C. This suggests that †Kenyon used an unidentified serial number file picture of 9111.C., because as late as 1991 very little was known of the presentation Luger carbine series including, apparently, the complete serial number range. It is interesting that in the page 64 text information, †Kenyon states a range of 9101.C. – 9110.C., yet pictures a partial top view of 9111.C. This suggests that †Kenyon used an unidentified serial number file picture of 9111.C., because as late as 1991 very little was known of the presentation Luger carbine series including, apparently, the complete serial number range.

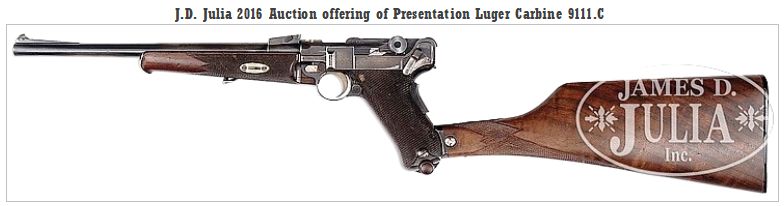

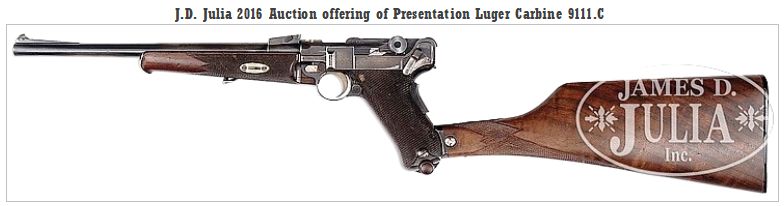

---------------- page 6 ---------------

The next information on pre-production presentation Luger carbine 9111.C. was 19 years later in the © 2010 & 2011TBLAP publication by †Gortz/Sturgess where 9111.C. was briefly discussed in volume I, Chapter 3, page 247 with no mention of a mating stock. No further specific, detailed information on 9111.C., complete with its unique single-screw tang, push-button attaching iron hunting carbine stock was not published until another 6 years later in an October 4, 2016 auction offering by Morphy’s Auction where 9111.C. was briefly discussed in volume I, Chapter 3, page 247 with no mention of a mating stock. No further specific, detailed information on 9111.C., complete with its unique single-screw tang, push-button attaching iron hunting carbine stock was not published until another 6 years later in an October 4, 2016 auction offering by Morphy’s Auction of presentation Luger carbine 9111.C. which included a detailed description of presentation Luger carbine 9111.C. which included a detailed description with a single, left-side profile picture of carbine and stock. with a single, left-side profile picture of carbine and stock. It is curious that all internet searched, indentified pictures of 9111.C. auctioned on October 4, 2016, purportedly by Morphy’s Auctions, have J.D. Julia superinposed logos It is curious that all internet searched, indentified pictures of 9111.C. auctioned on October 4, 2016, purportedly by Morphy’s Auctions, have J.D. Julia superinposed logos , even though Morphy Auctions didn’t merge with J.D. Julia , even though Morphy Auctions didn’t merge with J.D. Julia until December 2017. until December 2017.

The next appearance of pre-production presentation Luger carbine 9111.C. and mating single-screw tang, push-button attaching iron hunting carbine stock was at the January 2017 Las Vegas Antique Arms Gun Show being offered by Robert Simpson of Simpson Ltd. A discussion at Simpson’s table revolved around the lack of the full four-digit 9111 serial number on the single-screw tang, push-button attaching iron, hunting carbine wooden stock, normally located on the upper or lower tang.

Simpson had no answer, but a detailed inspection of the attaching iron, while detaching the single-screw tang, push-button stock from the 9111.C. first frame forging Luger carbine stock lug for release, required the depressing of the left-side attaching iron spring loaded, slotted push-button to release the opposite side “U” shaped hook from the right-side stock lug channel slot, allowing the stock to be removed from the Luger carbine first frame forging, knife-edge, push-button stock lug. As a result of depressing the left-side attaching iron spring-loaded push-button, forced the normally flush opposite side, retangular shaped, in profile portion of the push-button assembly to extend beyond the surrounding attaching iron surface.

During this process it was noticed that the last two-digits of the 91(11) serial number were stamped on top of the right-side, extended surface edge of the push-button assembly. Actually, with the spring-loaded button of the left-side push-button assemby depressed to its maximum reveals/exposes the opposite right side of only the top half of the numbers. This strongly supports that the application or stamping of the last two-digits of the 91(11).C. serial number was done by DWM prior to assembly of the single-screw tang, push-button attaching iron, Actually, with the spring-loaded button of the left-side push-button assemby depressed to its maximum reveals/exposes the opposite right side of only the top half of the numbers. This strongly supports that the application or stamping of the last two-digits of the 91(11).C. serial number was done by DWM prior to assembly of the single-screw tang, push-button attaching iron, in addition to the near identical numeric font size and style compared to some small part stampings of 9111.C. in addition to the near identical numeric font size and style compared to some small part stampings of 9111.C.

There could be several reasons for this hidden style stamping, possibly involving the Morphy (actually J.D. Julia) auction description statement that: the Wood on stock has been refinished and checkering has been re-cut. This rework may have required the removal of the attaching iron, inadvertently replacing the original, externally numbered, single-screw tang attaching iron This rework may have required the removal of the attaching iron, inadvertently replacing the original, externally numbered, single-screw tang attaching iron with an unnumbered “spare”, although this would not explain the DWM commercial, hidden style placement of the last two-digits of the serial number on the spring-loaded, push-button assembly, which, though highly unlikely, could have been added later. Regarding the auction description and later in the Simpson description of the stock being re-“checkered” simply “parrots” the J.D. Julia auction description[6], however, a refinished wooden stock is doubtful as a personal, detailed inspection of the 91(11) first pattern, single-screw tang, push-button hunting carbine wooden stock does not show or exhibit any evidence of being refinished or re-cut checkering. with an unnumbered “spare”, although this would not explain the DWM commercial, hidden style placement of the last two-digits of the serial number on the spring-loaded, push-button assembly, which, though highly unlikely, could have been added later. Regarding the auction description and later in the Simpson description of the stock being re-“checkered” simply “parrots” the J.D. Julia auction description[6], however, a refinished wooden stock is doubtful as a personal, detailed inspection of the 91(11) first pattern, single-screw tang, push-button hunting carbine wooden stock does not show or exhibit any evidence of being refinished or re-cut checkering.

Regarding the possibly aftermarket application of the last two-digits of the serial number being hidden would serve no practical purpose. Therefore, the hidden commercial style stamping of the last two-digits of the serial number should be considered original, making the single-screw tang push-button attaching iron hunting carbine wooden stock, by default, original to pre-production hybrid presentation carbine 9111.C., its two-digit serial number placement being a prerogative of the original DWM assembler, as are, possibly, the last two-digits of the serial number on the flaming bomb inspection stamped magazine wooden bottom.

The Old Switcheroo

After a review of the scholarly research of †Görtz/Sturgess in Pistole Parabellum ©2010, volume 3, chapter 19, page 1441, The Parabellum Magazine, figure 1371 regarding the evolution of the production Luger magazine machining revealed, that while the 9111.C. magazine wooden bottom 11 stamping is correct as is the magazine body, however, although while correct as an assembly, is not period correct for the 1901 made 9111.C. hybrid Presentation Carbine, based on the shape of the magazine exit lips, which indicate that the magazine was made in 1904 or later. ©2010, volume 3, chapter 19, page 1441, The Parabellum Magazine, figure 1371 regarding the evolution of the production Luger magazine machining revealed, that while the 9111.C. magazine wooden bottom 11 stamping is correct as is the magazine body, however, although while correct as an assembly, is not period correct for the 1901 made 9111.C. hybrid Presentation Carbine, based on the shape of the magazine exit lips, which indicate that the magazine was made in 1904 or later.

Also, the serial number 11 wooden bottom magazine is unusual for 9111.C. in as much as no C-suffix Presentation Carbines identified in this article has a wooden bottom serial numbered magazine, nor for that matter a GL logo wooden bottom magazine. Perhaps a previous owner of 9111.C. obtained the serial numbered magazine, not knowing of the subtleties of pre and post 1904 magazine machining, thought it appropriate.

The last seller, a dealer, as part of the description write-up of 9111.C. made the following comment, simply parroting the previous 2016 J. D. Julia auction description that the: Wood bottom mag has flaming bomb proof and added numbers that match, of which incidentally, the flaming bomb is a DWM factory inspection mark, not a proof. While indirectly saying the magazine may not be original to 9111.C. with numbers being “added” is also not totally accurate, with the authenticity being based solely on the “added” numbers and not on the significant fact that is, most importantly, it is the magazine body that is not correct. While indirectly saying the magazine may not be original to 9111.C. with numbers being “added” is also not totally accurate, with the authenticity being based solely on the “added” numbers and not on the significant fact that is, most importantly, it is the magazine body that is not correct.

---------------- page 7 ---------------

Here is where the story gets interesting, as also part of the LOB collection is another special Luger, being a 1913 Troops Trials pre-production prototype Artillery Luger with a two-digit serial number 11 with commercial style applied, hidden serial numbers. The plain, unnumbered wooden bottom and magazine body that came with the gun was always thought to be correct, however, based again on the †Görtz/Sturgess data collection is another special Luger, being a 1913 Troops Trials pre-production prototype Artillery Luger with a two-digit serial number 11 with commercial style applied, hidden serial numbers. The plain, unnumbered wooden bottom and magazine body that came with the gun was always thought to be correct, however, based again on the †Görtz/Sturgess data that the magazine is pre 1904 based on the shape or profile of the magazine body exit lips, being incorrect for a 1913 made, two-digit serial numbered Artillery Luger. Pictured for reference are the barrel underside and stop lug serial number stampings of 91(11) C. and 1913 prototype LP08 serial number 11. that the magazine is pre 1904 based on the shape or profile of the magazine body exit lips, being incorrect for a 1913 made, two-digit serial numbered Artillery Luger. Pictured for reference are the barrel underside and stop lug serial number stampings of 91(11) C. and 1913 prototype LP08 serial number 11.

So, it turns out that the post 1904 manufacture magazine with wooden bottom stamped serial number 11 is age or period appropriate for the 1913 prototype Artillery Luger serial number 11 and accordingly the pre 1904 magazine with unmarked, plain wooden bottom that came with prototype LP08 serial number 11 would be correct for 1901 Presentation Carbine 9111.C. This is not to say that this makes both magazines original to both Lugers, just that both magazines are otherwise now, period appropriate to their respective Lugers.

Since 1901 hybrid Presentation Carbine 9111.C. has a GL logo stamped rear link, one would think that a GL logo stamped wooden bottom pre-1904 magazine one would think that a GL logo stamped wooden bottom pre-1904 magazine would be more appropriate, based on other dual GL rear link and magazine GL wooden bottom examples being circa 1901 Chilean Carbine 10005 and circa 1904/5 New Model prototype 10051B. would be more appropriate, based on other dual GL rear link and magazine GL wooden bottom examples being circa 1901 Chilean Carbine 10005 and circa 1904/5 New Model prototype 10051B. One conclusion being the combination or occurrence of a GL logo stamped rear link and a GL logo stamped wooden bottom is totally arbitrary and capricious. One conclusion being the combination or occurrence of a GL logo stamped rear link and a GL logo stamped wooden bottom is totally arbitrary and capricious.

Alternately, it is well-known that GL logo stamped wooden bottom magazines are a collectible item in of themselves, as a few collectors have at least one of them in their collections, which begs the question of how they were acquired and based on the †Görtz/Sturgess magazine research, their authenticity? If one assumes these GL marked magazines are not a random Luger accessory, but unique to a particular Presentation or pre-production New Model prototype Luger, would go a long way in explaining why the GL logo stamped rear links of, for example, the 1903 gold inlaid chamber crested Presentation Luger Carbines in this article, that all have plain wooden bottom magazines. their authenticity? If one assumes these GL marked magazines are not a random Luger accessory, but unique to a particular Presentation or pre-production New Model prototype Luger, would go a long way in explaining why the GL logo stamped rear links of, for example, the 1903 gold inlaid chamber crested Presentation Luger Carbines in this article, that all have plain wooden bottom magazines.

Again, if one assumes GL logo stamped Presentation Luger Carbines and New Model Luger prototypes originally came, assuming with only one GL logo stamped wooden bottom magazine with no GL

marked spare, that a lot of pilfering has been going on throughout the last 100 years or so with the inclination to categorize this phenomenon as an early variation of the old “switcheroo”. Pictured are three, stand-alone GL magazines in the collection, not associated with any particular Luger identified as:

- pre-1904 magazine with production riveted, domed follower button,

- pre-1904 flat follower button magazine and,

- a very rare, pre-1904 flat follower button magazine with an HGL or Herr Georg Luger stamped wooden bottom believed to be one of the first GL marked magazines.

More on 1901 Hybrid Presentation Carbine 9111.C.

Interestingly, with the January 2017 Las Vegas Antique Arms Gun Show identity of the hidden placement of the last two-digits of the 9111.C. serial number on the Presentation Hunting Carbine stock attaching iron push-button component , incredibly missed, initially by J.D. Julia in October 2016 where they state in their catalog description regarding the hunting carbine stock that: Unnumbered push button stock has highly figured walnut and a checkered horn buttplate with engraved screws, , incredibly missed, initially by J.D. Julia in October 2016 where they state in their catalog description regarding the hunting carbine stock that: Unnumbered push button stock has highly figured walnut and a checkered horn buttplate with engraved screws, and later also missed by Simpson Ltd as of January 2017. and later also missed by Simpson Ltd as of January 2017.

However, with the hidden serial number discovery, thereby makes the stock matching to the 9111.C. Presentation Luger Carbine, or now a matching rig. One would have thought, that Simpson would have immediately added this information to his web site description of 9111.C., enhancing its salability, however, this was not done and possibly, in addition to the poor quality pictures copied from the October 2016 J.D. Julia auction 9111.C. offering, One would have thought, that Simpson would have immediately added this information to his web site description of 9111.C., enhancing its salability, however, this was not done and possibly, in addition to the poor quality pictures copied from the October 2016 J.D. Julia auction 9111.C. offering, contributed to 9111.C. with matching Push-Button Presentation Luger Hunting Carbine stock, languishing on the Simpson Ltd web site for about three-years, when it finally sold for an undisclosed, lower than stated, discounted amount in October 2021. contributed to 9111.C. with matching Push-Button Presentation Luger Hunting Carbine stock, languishing on the Simpson Ltd web site for about three-years, when it finally sold for an undisclosed, lower than stated, discounted amount in October 2021.

The first Frame Forging with Knife-Edge Push-Button Style Stock Lug

The first frame forging with knife-edge push-button style stock lug used for the subject, circa 1903 chamber dated C-suffix presentation carbines were most likely, as stated by †Görtz/Sturgess, spare frames originally made for the Chilean carbine series used with the first design, flat board stocks with the single-screw tang, push-button, attaching iron. Most likely the first frame forging, knife-edge, push-button stock lugs were later modified to accept the new, interim design hunting carbine wooden stock with single-screw tang, turn-lever attaching iron. Most likely the first frame forging, knife-edge, push-button stock lugs were later modified to accept the new, interim design hunting carbine wooden stock with single-screw tang, turn-lever attaching iron.

---------------- page 8 ---------------

The “Chilean” first forging frames used were were additionally modified by adding the “first design” hunting carbine forstock tang to the frame front and using the final design, wide grip safety, which, based on the apparent different angled or italicized type of application of the last two-digits of the serial number as compared to the other small parts standard, vertical stampings indicates that the original, narrow grip safety was changed-out, i.e. repaced with a wide grip safety Interestingly, the bottom edge of the Sear Bar is similiarly stamped, apparently at the same time of the replacement wide Grip Safety. and using the final design, wide grip safety, which, based on the apparent different angled or italicized type of application of the last two-digits of the serial number as compared to the other small parts standard, vertical stampings indicates that the original, narrow grip safety was changed-out, i.e. repaced with a wide grip safety Interestingly, the bottom edge of the Sear Bar is similiarly stamped, apparently at the same time of the replacement wide Grip Safety. [7] [7]

Assuming that the wide grip safey has a totally different, italicized looking, last two-digits serial number stamping suggests that the frame lacked an original serial number stamped narrow grip safety and that the wide grip safety was added, not being a replacement and, conversly, the similarly stamped Sear Bar, for reasons unknown, was also not part of the original first frame forging assembly. Pictured for comparision are a collage of the 9111.C. serialized, individual parts.

The Forestock And Forestock Tang

Pictured are three views of the wooden Forestocks of pre-production prototype, two-digit Luger Carbine 58, the subject Presentation hybrid Luger Carbine 9111.C. and the Forestock of final production frame Luger Carbine 23526. The internal cavity of 9111.C. and 23526 are basically identical with the now standard plunger assist mechanism, while the distinctly different cavity dimensions of Carbine Forestock 58, without the yet to be adopted plunger assist mechanism, are unique to the two-digit pre-production Luger Carbine Forestocks. Viewed externally, the hatching pattern of all three examples differ slightly with the 9111.C. bottom view shows the tip of the hatching pattern to extend further forward toward the nib end of the forestock termination. The internal cavity of 9111.C. and 23526 are basically identical with the now standard plunger assist mechanism, while the distinctly different cavity dimensions of Carbine Forestock 58, without the yet to be adopted plunger assist mechanism, are unique to the two-digit pre-production Luger Carbine Forestocks. Viewed externally, the hatching pattern of all three examples differ slightly with the 9111.C. bottom view shows the tip of the hatching pattern to extend further forward toward the nib end of the forestock termination.

The forstock tang installed on the 9111.C. frame front is identical to the one installed on 1901 pre-production-prototype Carbine 58. In this respect the 9111.C. first frame forging, knife-edge, push-button stock lug is dimensionally/structurally identical to Carbine 58. Click here to read about the Carbine 58 forestock tang. Cosmetically though, the first frame carbine forgings vs the final frame production carbine forgings are different where the DWM craftsmen, regarding Presentation Carbine 9111.C. first frame forging, took the extra effort to blend the interface transition of the forward curved gripstrap to the straight wall, flat trigger guard, similar to the apprroximately three years earlier, twenty Swiss Test Trials 1899 Borchardt Lugers. One can assume this extra step was done to all the C-suffix presentation carbines, however, without a personal examination of other examples it cannot be caterorically certain. Pictured together are the forward curved gripstrap, flat trigger guard blended interface of 1899 Borchardt Luger, 23, 1901 pre-production prototype carbine 58, 1904/5 production carbine 23526 and 1903 pre-production hybrid presentation carbine 9111.C. Pictured together for direct comparison are 9111.C. and 23526. Pictured together for direct comparison are 9111.C. and 23526.

A classic example is 9109.C. with the new, interim design hunting carbine wooden stock with single-screw, turn-lever attaching iron, per the auction description, (re) numbered to the carbine. Presentation Carbine 9116.C. is unusual, specifically in that it is mated with the final production design hunting carbine wooden stock with the larger size, two-screw, turn-lever attaching iron. Since the first frame forging knife-edge push-button stock lug was not designed to accept the the larger, final production size, two-screw attaching iron, both the 9116.C. push-button, knife-edge stock lug and two-screw tang, larger proportioned production, two-screw tang, turn-lever attaching iron and production stock lug needed modification to attach. Presentation Carbine 9116.C. is unusual, specifically in that it is mated with the final production design hunting carbine wooden stock with the larger size, two-screw, turn-lever attaching iron. Since the first frame forging knife-edge push-button stock lug was not designed to accept the the larger, final production size, two-screw attaching iron, both the 9116.C. push-button, knife-edge stock lug and two-screw tang, larger proportioned production, two-screw tang, turn-lever attaching iron and production stock lug needed modification to attach.

The final production two-screw securing tang, turn-lever attaching iron presentation hunting carbine stock mating to 9116.C. contradicts the comments made by †C. Kenyon, Jr. in Lugers at Random on page 80 General Notes where he states that: …nor can a standard stock be fitted to the special lug of a presentation model (1900 or 1902). on page 80 General Notes where he states that: …nor can a standard stock be fitted to the special lug of a presentation model (1900 or 1902). The conclusion being that 9116.C. presentation carbine frame forging is the final, production frame forging with “beefed-up” stock lug, which, if correct would additionally, contradict the †Görtz/Sturgess comments in Pistole Parabellum The conclusion being that 9116.C. presentation carbine frame forging is the final, production frame forging with “beefed-up” stock lug, which, if correct would additionally, contradict the †Görtz/Sturgess comments in Pistole Parabellum and TBLAP and TBLAP that “all” the four-digit C-suffix frames are of the knife-edge, first frame forgings. Although, in viewing the 9116.C. stock lug/attaching iron in profile, the connection appears to be of a knife-edge, first frame forging vs. a production frame carbine/attaching iron interface. that “all” the four-digit C-suffix frames are of the knife-edge, first frame forgings. Although, in viewing the 9116.C. stock lug/attaching iron in profile, the connection appears to be of a knife-edge, first frame forging vs. a production frame carbine/attaching iron interface.

This mating issue of 9116.C. is similar to 1901 presentation Luger carbine 10008, which is also mated to a very unusual, larger production dimensioned, 2-screw tang attaching iron, excepting that the attaching iron sports a larger diameter push-button vs. the expected turn-lever method of attachment, which is explained in detail in text and pictures in an associated article on this site titled: 10008 Chilean type carbine prototype presentation, pages 4 and 5. It is possible that the 9116.C. frame is production and not a first frame, knife edge, push-button forging. Unfortunately, there are no detailed, close-up pictures of the 9116.C. frame stock lug to verify what frame was used. Additionally, since the hunting carbine stock used was the final, two-screw tang attaching iron, turn-lever production design means, most likely, the production frames were also concurrently available. which is explained in detail in text and pictures in an associated article on this site titled: 10008 Chilean type carbine prototype presentation, pages 4 and 5. It is possible that the 9116.C. frame is production and not a first frame, knife edge, push-button forging. Unfortunately, there are no detailed, close-up pictures of the 9116.C. frame stock lug to verify what frame was used. Additionally, since the hunting carbine stock used was the final, two-screw tang attaching iron, turn-lever production design means, most likely, the production frames were also concurrently available.

---------------- page 9 ---------------

A Primer on the Push-Button Stock Lug and Single-Screw Tang Push-Button Attaching Iron Configuration

The highlighted, underlined text pictured was excerpted from the Sept-2004 Gun Report magazine was excerpted from the Sept-2004 Gun Report magazine monthly Lugers At Random Q&A column by †Charlie Kenyon, Jr. In his column where he discusses the Push-Button stocks, he is referring to the Chilean Luger Carbine 10000 – 10050 series, flat board-stocks with single-screw tang attaching irons. Although, to be accurate, the early pre-production Luger Hunting Carbine stocks were also fitted with the single-screw tang, Push-Button attaching irons, an example being Luger Hunting Carbine stock 35. monthly Lugers At Random Q&A column by †Charlie Kenyon, Jr. In his column where he discusses the Push-Button stocks, he is referring to the Chilean Luger Carbine 10000 – 10050 series, flat board-stocks with single-screw tang attaching irons. Although, to be accurate, the early pre-production Luger Hunting Carbine stocks were also fitted with the single-screw tang, Push-Button attaching irons, an example being Luger Hunting Carbine stock 35.

Kenyon states that the first frame forging, knife-edge stock lug and the single-screw tang, push-button stock attaching iron – had to be manufactured so that they could fit together with relative ease, resulting in some inherent weakness of side-play or wobble. This counters the accepted notion that the early production Push-Button stock lug/single-screw tang Attaching Iron configurations were custom, individually fitted, i.e. not interchangeable.

This left-to-right wobble as described by †Kenyon was initially attributed to much use and wear, however, the looseness was, apparently, according to †Kenyon, present at production. This looseness is encountered with two such single-screw tang, push-button stock matching rigs in the collection, the subject Presentation Hunting Carbine 9111.C. and Chilean Luger Carbine 10035 with flat board-stock and Chilean Luger Carbine 10035 with flat board-stock . .

Interestingly, the 9111.C. Push-Button Hunting Carbine stock, single-screw attaching Iron will easily connect to the knife-edge, Push-Button stock lug of GL Chilean presentation, multi-position, 2-4-6 adjustable tangent rear sight of 10005 and also to fixed rear sight BUG proofed Chilean Luger Carbine 10035 and also to fixed rear sight BUG proofed Chilean Luger Carbine 10035 and the 100(35) numbered flat board-stock, Push-Button stock attaching Iron also connects to the Presentation/hybrid 9111.C. knife-edge, Push-Button stock lug and the 100(35) numbered flat board-stock, Push-Button stock attaching Iron also connects to the Presentation/hybrid 9111.C. knife-edge, Push-Button stock lug and another interesting Push-Button Carbine combination. and another interesting Push-Button Carbine combination. Apparenly, the side-play or wobble did allow automatic interchangeability within the Push-Button series. It is not certain this interchangeability extends to the production, two-screw tang, Turn-Lever Hunting Carbine series. Apparenly, the side-play or wobble did allow automatic interchangeability within the Push-Button series. It is not certain this interchangeability extends to the production, two-screw tang, Turn-Lever Hunting Carbine series.

The additional †Kenyon comments that the side-to-side wobble issue was corrected in short order is an understatement as the attaching iron, single-screw tang, Turn-Lever redesign was not applied to the flat-board stock, that ship had sailed, as there are no examples of single-screw tang, turn-lever attaching irons affixed to flat board stocks. However, the interim Turn-Lever design, soon to be also quickly eclipsed, appear to be affixed, exclusively to the early 9100, C-suffix series Presentation Luger Hunting Carbines, 9102.C. as an example. This is somewhat supported by circa 1901 Chilean Luger carbine presentation, 2-4-6 multi-position, adjustable tangent rear sights of 10005 & 10010, and circa 1901 Presentation Luger Hunting Carbines 9110.C. This is somewhat supported by circa 1901 Chilean Luger carbine presentation, 2-4-6 multi-position, adjustable tangent rear sights of 10005 & 10010, and circa 1901 Presentation Luger Hunting Carbines 9110.C. and 9111.C. and 9111.C. with Push-Button stock lugs modified to accept the first interim turn-lever attaching irons, interestingly, mostly with single-screw, attaching iron tangs. with Push-Button stock lugs modified to accept the first interim turn-lever attaching irons, interestingly, mostly with single-screw, attaching iron tangs.

The above scenario creates yet another issue of what Luger carbine variation used the new, interim single-screw tang, turn-lever attaching Iron. Since the new turn-lever attaching Iron was affixed to Hunting Carbine stocks in the 9100 C-suffix, hybrid series Presentation Hunting Carbines, would be the logical recipients. However, the frames used for the Presentation Hunting Carbine series were “spare” first frame forgings with knife-edge, push-button stock lugs.

Apparently, the first frame forging, knife-edge Push-Button stock lugs of the short run (9102.C. – 9116.C.) Presentation Hunting Carbine series were modified at manufacture to accept the new, interim design, single-screw tang Turn-Lever Attaching Irons. The inference being that none of the Presentation Hunting Carbine series used Push-Button hunting Carbine stocks with the exception of 9110.C and recently identified 9111.C., and recently identified 9111.C., which is also affixed to a serialized, matching Push-Button Hunting Carbine stock, while ironicaly the 9111.C. Push-Button stock lug has been modified to accept the new interim single-screw tang, Turn-Lever hunting carbine stock. which is also affixed to a serialized, matching Push-Button Hunting Carbine stock, while ironicaly the 9111.C. Push-Button stock lug has been modified to accept the new interim single-screw tang, Turn-Lever hunting carbine stock.

The 9111.C. single-screw tang, push-button attaching iron hunting carbine stock