Circa 1904/5 transitional New Model GL logo 9 mm prototype S/N 10078B

Circa 1904/5 transitional New Model GL logo 9 mm prototype S/N 10078B is, as of this writing being offered, as of 3 August 2018 by an American Midwest firearms dealer Simpson Ltd , described as: , described as:

DWM 1904/1906 TRANSITION PROTOTYPE. SKU: C40757 $115,000.00. Date Added: Friday, 03 Aug, 2018

9 mm; GL marked on rear toggle, with Powell cartridge counter features. Thought to have been presented by George Luger to the inventor of the cartridge counter system for the Luger. Condition is 90*95% original blue, straw, bore and grips, with all original parts, finish and markings. Matching numbers. Provenance: Two articles written about this pistol, man at ARMS, volume five, number three, May/June 1983 and The GUN REPORT, volume 50, Number 9, February 2005 and The GUN REPORT, volume 50, Number 9, February 2005 . .

In the 1983 man at ARMS , © 1982 Providence, R.I. article titled: “Rare Lugers Still Emerge” , © 1982 Providence, R.I. article titled: “Rare Lugers Still Emerge” by Major Richard J. Keogh by Major Richard J. Keogh [1] 10078B is described as a transitional New Model 9 mm Luger with the following mechanical features: [1] 10078B is described as a transitional New Model 9 mm Luger with the following mechanical features:

The Old Model frame has been shortened from 131 mm to 129 mm and the Old Model, dual leaf riband mainspring has been replaced and reconfigured with a New Model coiled mainspring, with no other changes to the frame, except for a modification to the left side frame magazine channel upper web to accommodate a Cartridge Counter wooden grip and magazine.

Per the 1983 man at ARMS article the Old Model American Eagle chamber crested, long frame receiver has also been shortened from 131 mm to 129 mm, manufactured with a New Model chamber face, cut for the interim narrow ear, New Model extractor tip, article the Old Model American Eagle chamber crested, long frame receiver has also been shortened from 131 mm to 129 mm, manufactured with a New Model chamber face, cut for the interim narrow ear, New Model extractor tip, keeping the cut-back, Old to New Model receiver, but retaining the Old Model ejector and sear bar flat leaf spring/spring channel configuration/dimensions. keeping the cut-back, Old to New Model receiver, but retaining the Old Model ejector and sear bar flat leaf spring/spring channel configuration/dimensions.

The 1983 man at ARMS article description of the receiver chamber face configuration differs from a later 2005 Gun Report article description of the receiver chamber face configuration differs from a later 2005 Gun Report article on s/n 10078B by C. Kenyon where he states: The Old Model receiver chamber face has been modified to accept an interim narrow ear, New Model extractor and the (Old Model receiver chamber face) “notched” to accept the breechblock, narrow ear extractor of the New Model toggle assembly. article on s/n 10078B by C. Kenyon where he states: The Old Model receiver chamber face has been modified to accept an interim narrow ear, New Model extractor and the (Old Model receiver chamber face) “notched” to accept the breechblock, narrow ear extractor of the New Model toggle assembly. This differs with the 1983 man at ARMS This differs with the 1983 man at ARMS description, which implies that the receiver was “manufactured” with the New Model chamber face extractor cut(s). description, which implies that the receiver was “manufactured” with the New Model chamber face extractor cut(s).

A comment made in the 1983 man at ARMS article on page 22 regarding the receiver is: The absence of proofmarks would tend to substantiate the belief that this is an experimental or presentation piece, not part of a production run. This conclusion is generally accurate for most B-suffix plain chambered, transitional New Model Lugers, such as 10051B, 10069B and 10070B, however, not necessarily or completely accurate for 10078B, in as much as the receiver used is an Old Model, production roll die, chamber crested American Eagle. article on page 22 regarding the receiver is: The absence of proofmarks would tend to substantiate the belief that this is an experimental or presentation piece, not part of a production run. This conclusion is generally accurate for most B-suffix plain chambered, transitional New Model Lugers, such as 10051B, 10069B and 10070B, however, not necessarily or completely accurate for 10078B, in as much as the receiver used is an Old Model, production roll die, chamber crested American Eagle.

Additionally, the receivers of imported Old Model 120 mm or 4¾-inch barreled American Eagle Lugers are noted for the lack of commercial BUG proofs on the receiver left side, nor on any other components, including the barrel and toggle link assembly, with BUG proofs seen mostly on plain chamber commercial Lugers. Although, most imported Old Model American Eagle Lugers were GERMANY export stamped of the frame front, under the serial number, starting in the low 2000 serial number range, which may have been the case with the original 10078 frame serial number, which was removed when shortening the frame from 131 mm to 129 mm, then stamping/restamping the original 10078 frame serial number and adding the B-suffix letter.

An important Old Model added feature that should be present, when examining a transitional prototype receiver chamber face is discussed in TBLAP, VI, C3, page 228. Another change which was introduced, intermittently after approximately serial number 12000[2] of the commercial Old Model production pistols was a relief cut for the extractor in the top of the chamber face of the receiver ring. This was a simple slot, beveled down and forwards, approximately 6 mm wide x 0.8 mm deep, let into the curve of the edge between the inside, threaded bore and the chamber face of the receiver ring VI, C3, page 228. Another change which was introduced, intermittently after approximately serial number 12000[2] of the commercial Old Model production pistols was a relief cut for the extractor in the top of the chamber face of the receiver ring. This was a simple slot, beveled down and forwards, approximately 6 mm wide x 0.8 mm deep, let into the curve of the edge between the inside, threaded bore and the chamber face of the receiver ring to provide additional relief for the Old Model extractor above the normal extractor cut in the barrel. to provide additional relief for the Old Model extractor above the normal extractor cut in the barrel.

All Old to New Model, caliber 9 mm 10000B-series, transitional prototype receiver chamber face conversions examined to date have remnants of this now, non-functioning bevel on each side of the added New Model extractor cut, which includes 10051B, 10069B, 10070B, 10069B, 10070B, 10078B 10078B and the circa 1903, 30 caliber French Chargé Lugers. and the circa 1903, 30 caliber French Chargé Lugers.

Kenyon in the 2005 Gun Report article also, in this case, incorrectly states that the 10078B receiver Old Model ejector has been replaced with a New Model ejector, which was not done. This requires the right-side receiver fork ejector anchor slot to be extensively modified/relocated as illustrated in the New Model GL prototype 10051B right-side receiver fork inside wall, article also, in this case, incorrectly states that the 10078B receiver Old Model ejector has been replaced with a New Model ejector, which was not done. This requires the right-side receiver fork ejector anchor slot to be extensively modified/relocated as illustrated in the New Model GL prototype 10051B right-side receiver fork inside wall, however, an inspection of the actual 10078B Old Model, shortened receiver shows the original Old Model ejector with its original, unmodified anchor position. however, an inspection of the actual 10078B Old Model, shortened receiver shows the original Old Model ejector with its original, unmodified anchor position.

1

In the converted Old Model receivers of 10051B, 10069B and 10070B the receiver left side sear bar flat leaf spring was lengthened, which required extending rearward the receiver sear bar, flat leaf spring channel. Interestingly, the 10078B receiver retains the, as manufactured, Old Model shorter sear bar, flat leaf spring configuration. Pictured for comparison are the receiver sear bar, flat leaf spring configurations of 10051B and 10078B.

Although the transitional, New Model breechblock with narrow ear extractor was used in the very few 10000B transitional New Model Lugers and the approximately 25[3] transitional, late Old Model production short frame 1903 French Chargé Lugers was used in the very few 10000B transitional New Model Lugers and the approximately 25[3] transitional, late Old Model production short frame 1903 French Chargé Lugers with the late Old Model, short frame receiver, ring top rounded edge chamber faces, they were modified (by notching) as described by Kenyon of 10078B, to accept the New Model, narrow ear extractor. with the late Old Model, short frame receiver, ring top rounded edge chamber faces, they were modified (by notching) as described by Kenyon of 10078B, to accept the New Model, narrow ear extractor.

Actually, Kenyon was correct regarding the 10078B chamber face being post manufacture “notched”, which was done to accommodate the New Model, narrow ear extractor top side, angled protruding tip, which was verified by actual, multiple views of the 10078B toggle link assembly, generously provided by Simpson Ltd. Interestingly, the 10078B Old Model chamber face receiver ring appears, at first glance, to be stepped as in production. generously provided by Simpson Ltd. Interestingly, the 10078B Old Model chamber face receiver ring appears, at first glance, to be stepped as in production.

However, the appearance is a result of the concave shaped step (scoop) being applied to the top surface of a round receiver ring top, done to allow for clearance of the protruding New Model, narrow ear extractor tip vs. the same concave step being done to the final transitional New Model prototype, 10051B as an example, where the Old Model chamber receiver top was machined flat or elliptical, leaving less metal, resulting in a receiver ring step, showing remnants of the receiver ring rounded top edge, typical of the only known three, final New Model

prototypes 10051B, 10069B and 10070B typical of the only known three, final New Model

prototypes 10051B, 10069B and 10070B . The same New Model receiver step appearance is also evident in the 10110.C. New Model carbine prototype of the same Old Model chamber face, stepped receiver ring appearance of 10078B. . The same New Model receiver step appearance is also evident in the 10110.C. New Model carbine prototype of the same Old Model chamber face, stepped receiver ring appearance of 10078B. Actually, the 10110.C. carbine receiver chamber face extractor cut appears to be of production manufacture, using an Old Model 131 mm length receiver. Actually, the 10110.C. carbine receiver chamber face extractor cut appears to be of production manufacture, using an Old Model 131 mm length receiver.

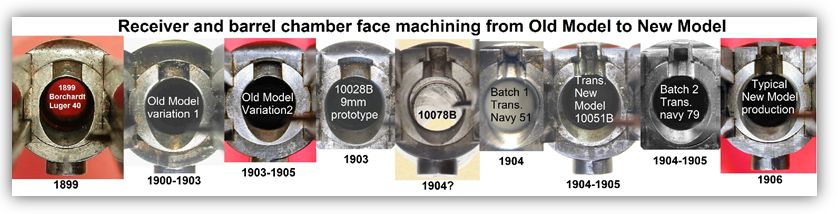

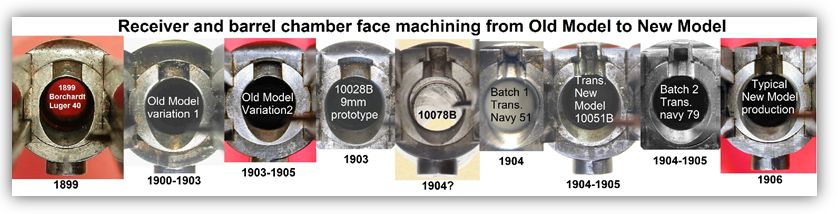

Per TBLAP it wasn’t until the 1904 transitional, long frame navy Lugers with their identical transitional, but navy proofed breechblocks with narrow ear extractors, it wasn’t until the 1904 transitional, long frame navy Lugers with their identical transitional, but navy proofed breechblocks with narrow ear extractors, were the transitional/hybrid Old Model, long frame receivers with the Old Model ejector and shorter sear bar, flat leaf spring finally “manufactured” with the New Model receiver ring top step edge, chamber face extractor cuts, and even then, there are a few, circa M1904 Transitional Navy stragglers with modified (notched) Old Model receiver ring rounded top edge chamber face extractor cuts, were the transitional/hybrid Old Model, long frame receivers with the Old Model ejector and shorter sear bar, flat leaf spring finally “manufactured” with the New Model receiver ring top step edge, chamber face extractor cuts, and even then, there are a few, circa M1904 Transitional Navy stragglers with modified (notched) Old Model receiver ring rounded top edge chamber face extractor cuts, similar to transitional New Model prototypes 10051B, 10069B and 10070B similar to transitional New Model prototypes 10051B, 10069B and 10070B . Pictured

is one example each of a transitional New Model receiver chamber face and circa 1903 French Chargé chamber face vs. a 1904 transitional navy Luger chamber face vs. typical production. . Pictured

is one example each of a transitional New Model receiver chamber face and circa 1903 French Chargé chamber face vs. a 1904 transitional navy Luger chamber face vs. typical production.

The Luger Book by J. Walters © 1986 states on page 236 in a paragraph titled R13 Receivers that: The new receivers (Gabelgehäuse neuer Art, or 2. Serie) are used in conjunction with the combination extractor/loaded chamber indicator, the stepped rear edge of the receiver-ring being grooved vertically for the extractor blade. They are found on the experimental transitional pistols of 1904 and all New Model Parabellums. by J. Walters © 1986 states on page 236 in a paragraph titled R13 Receivers that: The new receivers (Gabelgehäuse neuer Art, or 2. Serie) are used in conjunction with the combination extractor/loaded chamber indicator, the stepped rear edge of the receiver-ring being grooved vertically for the extractor blade. They are found on the experimental transitional pistols of 1904 and all New Model Parabellums.

TBLAP, V1 C3, page 228, Fig. 3-132 caption, section D states that: P.04 Naval Trials Transitional pistol sn. 51, however, has a new made New Model receiver without Old Model relief cut, though pistols with later serial numbers of this batch of Transitional Navy trials pistols have converted Old Model receivers with the relief cut, similar to the French Trial Transitional pistols. V1 C3, page 228, Fig. 3-132 caption, section D states that: P.04 Naval Trials Transitional pistol sn. 51, however, has a new made New Model receiver without Old Model relief cut, though pistols with later serial numbers of this batch of Transitional Navy trials pistols have converted Old Model receivers with the relief cut, similar to the French Trial Transitional pistols.

Although, in the TBLAP page 291, Fig. 3-192 text caption, while discussing/justifying certain aspects or features of the

transitional Navy Luger, states that there are two separate manufacturing batches of the transitional navy Lugers: ….this [ ] characteristic is seen

in genuine examples with serial numbers below approximately sn. 75, but is absent in higher numbered examples, which is consistent with these pistols having been made and delivered in two batches in July - August 1904, several minor changes in machining being noted in genuine examples with

higher serial numbers. page 291, Fig. 3-192 text caption, while discussing/justifying certain aspects or features of the

transitional Navy Luger, states that there are two separate manufacturing batches of the transitional navy Lugers: ….this [ ] characteristic is seen

in genuine examples with serial numbers below approximately sn. 75, but is absent in higher numbered examples, which is consistent with these pistols having been made and delivered in two batches in July - August 1904, several minor changes in machining being noted in genuine examples with

higher serial numbers.

2

The existence of two batches is somewhat verified, as a significant machining feature, although mentioned in TBLAP interestingly, also relating to the Old Model vs. New Model extractor cut and is of the same modification(s), is to the New Model barrel face, other than the change in the upper barrel face receiver cut to accommodate the lower, angled protrusion, concave sides of the New Model

extractor, being convex support added to each side of the New Model barrel extractor cut. interestingly, also relating to the Old Model vs. New Model extractor cut and is of the same modification(s), is to the New Model barrel face, other than the change in the upper barrel face receiver cut to accommodate the lower, angled protrusion, concave sides of the New Model

extractor, being convex support added to each side of the New Model barrel extractor cut.

Interestingly, the barrel face drawing, while showing the New Model receiver angled extractor cuts is pictured with the Old Model barrel face, smaller, standard original feed ramp. Secondly, the April 4, 1904 delivery of 50 circa 1904 Cartridge Counter Lugers to the U.S. Army, the 4-inch FAT barrel chamber face retains the Old Model barrel face, smaller feed ramp.

The second change has been mentioned in this article, but heretofore, not in association with the “two” batch scenario presented by TBLAP . The August/September 1904 first batch delivery of transitional navy Lugers with 150 mm pre-production navy FAT barrels below serial number 75, examples being serial numbers 36 and 51, the barrel, lower receiver face has the Old Model entrance feed ramp. . The August/September 1904 first batch delivery of transitional navy Lugers with 150 mm pre-production navy FAT barrels below serial number 75, examples being serial numbers 36 and 51, the barrel, lower receiver face has the Old Model entrance feed ramp.

The transitional navy Luger barrels above serial number 75, examples being serial numbers 79 and 136 and 136 have the New Model, enlarged entrance feed ramps, identical to the early 1905 made, final New Model 4-inch 9 mm barrel prototype Lugers 10051B, 10069B, 10070B, including the Old Model transitional receiver face extractor cuts. This additional feature further supports the TBLAP have the New Model, enlarged entrance feed ramps, identical to the early 1905 made, final New Model 4-inch 9 mm barrel prototype Lugers 10051B, 10069B, 10070B, including the Old Model transitional receiver face extractor cuts. This additional feature further supports the TBLAP notion of two distinct, separate batches. Coincidently, transitional navy Luger 136 is the only identified transitional navy Luger with an identical 136 serial numbered production Navy Luger. notion of two distinct, separate batches. Coincidently, transitional navy Luger 136 is the only identified transitional navy Luger with an identical 136 serial numbered production Navy Luger.

Per the TBLAP statement that the final transitional New Model prototypes 10051B, 10069B, 10070B with the barrel face enlarged feed ramp were made early 1905 suggests, at least a 4-month gap before the second batch delivery of transitional Navy Lugers, also with enlarged barrel chamber feed ramps. The 4-month delivery gap seems implausible based on the introduction of the enlarged barrel face feed ramp, which certainly preceded the three transitional New Model prototype Lugers mentioned, is first seen on B-suffix Cal 9 mm Lugers 10028B and 10030B with unmodified Old Model receivers and barrels with early to mid-1903 manufacturing dates[4], prior to the transitional navy first batch deliveries. statement that the final transitional New Model prototypes 10051B, 10069B, 10070B with the barrel face enlarged feed ramp were made early 1905 suggests, at least a 4-month gap before the second batch delivery of transitional Navy Lugers, also with enlarged barrel chamber feed ramps. The 4-month delivery gap seems implausible based on the introduction of the enlarged barrel face feed ramp, which certainly preceded the three transitional New Model prototype Lugers mentioned, is first seen on B-suffix Cal 9 mm Lugers 10028B and 10030B with unmodified Old Model receivers and barrels with early to mid-1903 manufacturing dates[4], prior to the transitional navy first batch deliveries.

TBLAP, V1 C3, page 228, Fig. 3-132 caption, section E additionally states that: - 9 mm New Model prototype sn. 10070B V1 C3, page 228, Fig. 3-132 caption, section E additionally states that: - 9 mm New Model prototype sn. 10070B also has a converted Old Model receiver, with extractor relief cut, adapted for the New Model extractor – note also the enlarged feed ramp compared to the Old Model and Transitional pistols. What, surprisingly, not mentioned, which is more significant is that the enlarged barrel feed ramp was introduced in the first Old Model, transitional 9 mm 4¾-inch FAT barrel prototypes, also has a converted Old Model receiver, with extractor relief cut, adapted for the New Model extractor – note also the enlarged feed ramp compared to the Old Model and Transitional pistols. What, surprisingly, not mentioned, which is more significant is that the enlarged barrel feed ramp was introduced in the first Old Model, transitional 9 mm 4¾-inch FAT barrel prototypes, with the earliest published serial number pistol being 10023B with the earliest published serial number pistol being 10023B with a 150mm or 5.9-inch 9 mm barrel, similar to the transitional navy Luger barrels (barrel feed ramp variation unknown) with 10028B with a 150mm or 5.9-inch 9 mm barrel, similar to the transitional navy Luger barrels (barrel feed ramp variation unknown) with 10028B , being the next identified 9 mm prototype with the enlarged barrel feed ramp, currently part of the LOB , being the next identified 9 mm prototype with the enlarged barrel feed ramp, currently part of the LOB collection, followed by 10030B. collection, followed by 10030B.

Since these first B-suffix 9 mm prototype pistols were made before, or possibly concurrent, to the first batch of transitional Navy Lugers, as defined by TBLAP , V1, C3, page 291, Fig. 3-192 text caption, it is curious that the first batch navy examples being 36 , V1, C3, page 291, Fig. 3-192 text caption, it is curious that the first batch navy examples being 36 and 51 were assembled with 150mm FAT barrels with the Old Model feed ramps, with purportedly, new manufactured receivers with production extractor cuts, while in the short time span after the first batch, the second batch of transitional navy Lugers, above serial number 75, were assembled with Old Model receivers with the same “Old Model” 150mm FAT barrels, except with the new, enlarged feed ramps, examples being 79 and 51 were assembled with 150mm FAT barrels with the Old Model feed ramps, with purportedly, new manufactured receivers with production extractor cuts, while in the short time span after the first batch, the second batch of transitional navy Lugers, above serial number 75, were assembled with Old Model receivers with the same “Old Model” 150mm FAT barrels, except with the new, enlarged feed ramps, examples being 79 and 136, and 136, both pistols being authenticated by Dr. G. L. Sturgess, specifically transitional navy 79 being addressed in a letter of authenticity both pistols being authenticated by Dr. G. L. Sturgess, specifically transitional navy 79 being addressed in a letter of authenticity . Pictured for comparison are the receiver chamber face extractor cuts and the barrel feed ramps of serial numbers of the first batch transitional navy Lugers 36, 51 and the second batch 79 and 136 transitional navy examples and a typical production example. . Pictured for comparison are the receiver chamber face extractor cuts and the barrel feed ramps of serial numbers of the first batch transitional navy Lugers 36, 51 and the second batch 79 and 136 transitional navy examples and a typical production example.

The implications of both The Luger Book and later in TBLAP and later in TBLAP that the first

batch transitional navy Luger receiver chamber faces are of the first “production” manufacture is not completely accurate, despite the fact of the straight wall receiver face and the lack of the Old Model bevel lip, the balance of the changes to the receiver face, being the inverted, three-sided, П shaped extractor cut appear to be of the production configuration, however, they are not production, but are of a pre-production DWM tool room, manually, hand applied interim nature. that the first

batch transitional navy Luger receiver chamber faces are of the first “production” manufacture is not completely accurate, despite the fact of the straight wall receiver face and the lack of the Old Model bevel lip, the balance of the changes to the receiver face, being the inverted, three-sided, П shaped extractor cut appear to be of the production configuration, however, they are not production, but are of a pre-production DWM tool room, manually, hand applied interim nature.

3

Pictured, labeled and marked-up for clarity are the receiver chamber face extractor cuts of transitional navy P04 Lugers 36, 51 and a typical production example. Also pictured, unmarked are the receiver chamber face extractor cuts and feed ramps of transitional navy Lugers 36, 51, 79, 136 and a production New Model receiver chamber face extractor cut example. Also pictured, unmarked are the receiver chamber face extractor cuts and feed ramps of transitional navy Lugers 36, 51, 79, 136 and a production New Model receiver chamber face extractor cut example.

Additionally, pictured below are the receiver barrel interface entrance feed ramps from an evolutionally point of view, which coincidently, are totally unrelated to any chronological serial number sequence, nor related to Old or New Model receiver face extractor machining.

This difference is easily noted by comparing the receiver chamber face extractor cuts of transitional navy

Luger serial numbers 36 and 51 compared against a typical production receiver face extractor cuts. Note, that in the typical production example the top surface of the inverted, three-sided, П shaped, blued cut is near flush with the top of the receiver surface, whereas, in 36 and 51 the white metal, unblued, rough surface, three-sided, inverted, П shaped extractor cut is decidedly lower, and shaped differently from the production example, and to each other. Note, that in the typical production example the top surface of the inverted, three-sided, П shaped, blued cut is near flush with the top of the receiver surface, whereas, in 36 and 51 the white metal, unblued, rough surface, three-sided, inverted, П shaped extractor cut is decidedly lower, and shaped differently from the production example, and to each other.

That the first batch transitional navy Luger receiver face is straight wall, with no rounded top surface does not involve any machining effort, simply using an, as manufactured, Old Model receiver before any receiver face machining is done, including the receiver bevel, and adding the New Model chamber top receiver step, although, importantly, what is decidedly more complicated, is adding the multi-faceted extractor cut to the upper receiver face. Note, the receiver chamber face, three-sided inverted, П shaped and angled extractor cuts were done before the barrel was installed.

Interestingly, the New Model drawing for the receiver and receiver “face” was done in the same, circa 1904/5 time frame manufacture of the transitional Navy Lugers, although, apparently the production set-up jigs were not done or available or simply not used, in as much as the transitional long frame navy receivers used were Old Model with the original ejector and short Sear Bar flat leaf spring and receiver channel, ergo, contrary to preexisting published assertions, the P04 transitional navy receiver face extractor cuts, examples being 36 and 51, are of an interim nature, and as such, the transitional Navy Luger receiver extractor cuts could be still considered hybrid as stated in TBLAP was done in the same, circa 1904/5 time frame manufacture of the transitional Navy Lugers, although, apparently the production set-up jigs were not done or available or simply not used, in as much as the transitional long frame navy receivers used were Old Model with the original ejector and short Sear Bar flat leaf spring and receiver channel, ergo, contrary to preexisting published assertions, the P04 transitional navy receiver face extractor cuts, examples being 36 and 51, are of an interim nature, and as such, the transitional Navy Luger receiver extractor cuts could be still considered hybrid as stated in TBLAP . .

Another modification, done to all the Old Model receivers mentioned, in addition to the receiver chamber face modifications for the New Model extractor, was to change the top of the Old Model receiver circumference from round or circular to elliptical, i.e. flattened, as noted earlier, in order to gain better visibility of the New Model extractor when loaded. This was not done to the 10078B receiver chamber top surface, which exhibits the Old Model circular surface. One obvious reason for not changing the 10078B receiver chamber top surface is that it would result in the partial removal of the American Eagle receiver chamber crest. One obvious reason for not changing the 10078B receiver chamber top surface is that it would result in the partial removal of the American Eagle receiver chamber crest.

Pictured are the tops of serial numbers 10051B, 10078B and a parts hybrid, similar to 10078B. Additionally, the fact that the 10078B American Eagle chamber crested receiver retains its round or circular surface, indicates that the receiver was not manufactured with the New Model stepped receiver ring and straight wall chamber face, but was post manufacture notched, as were transitional navy Lugers 36 and 51, to accept the new Model transitional breechblock, narrow ear extractor protruding tip. Additionally, the fact that the 10078B American Eagle chamber crested receiver retains its round or circular surface, indicates that the receiver was not manufactured with the New Model stepped receiver ring and straight wall chamber face, but was post manufacture notched, as were transitional navy Lugers 36 and 51, to accept the new Model transitional breechblock, narrow ear extractor protruding tip.

It is generally accepted that some of the 10000B-suffix Lugers were made for DWM internal tests and or demonstration purposes, for example, the three, only known, modified Old to New Model transitional Lugers with extensive, multiple modifications being 10051B, 10069B 10069B , 10070B , 10070B . However, most B-series Lugers were made to demonstrate some form of singular mechanical improvement or change. In the case of 10078B, setting aside the Cartridge Counter wooden grip, based on the unmodified American Eagle chamber crest, the intent errs more toward presentation than evolutionary prototype yet, interestingly, the New Model, P.08 style, 9 mm barrel is the first and only interim prototype example, in all aspects, identical to the New Model barrels used on 10051B, 10069B and 10070B, with the notable, “out of sequence” exception that the 10078B barrel face maintains the Old Model barrel feed ramp, . However, most B-series Lugers were made to demonstrate some form of singular mechanical improvement or change. In the case of 10078B, setting aside the Cartridge Counter wooden grip, based on the unmodified American Eagle chamber crest, the intent errs more toward presentation than evolutionary prototype yet, interestingly, the New Model, P.08 style, 9 mm barrel is the first and only interim prototype example, in all aspects, identical to the New Model barrels used on 10051B, 10069B and 10070B, with the notable, “out of sequence” exception that the 10078B barrel face maintains the Old Model barrel feed ramp, whereas, the 10051B, 10069B and 10070B barrel feed ramps are of the final, enlarged design whereas, the 10051B, 10069B and 10070B barrel feed ramps are of the final, enlarged design as stated earlier, ironically, are the first Old Model 9 mm prototypes, examples being 10028B and 10030B. as stated earlier, ironically, are the first Old Model 9 mm prototypes, examples being 10028B and 10030B.

4

The 10078B toggle link assembly was assembled with a standard Old Model DWM middle link, a New Model transitional breechblock with a narrow ear extractor, hand stamped “Loaded” and a New Model rear link with transitional, square faced, 60-degree hatching pattern toggle knobs with rounded toggle knob edges, similar to the mostly, final transitional New Model rear links, with one significant difference. was assembled with a standard Old Model DWM middle link, a New Model transitional breechblock with a narrow ear extractor, hand stamped “Loaded” and a New Model rear link with transitional, square faced, 60-degree hatching pattern toggle knobs with rounded toggle knob edges, similar to the mostly, final transitional New Model rear links, with one significant difference.

The 10078B GL logo stamped rear link maintains the Old Model characteristic, flush mount to receiver fork surface dimension and Old Model underside machining and Old Model coupling link vs. the later transitional New Model rear links, which are thicker and sit approximately 1 mm above the receiver forks top surface, and with New Model underside machining and New Model coupling link.

100(52)B[5]

Pictured is a similar, transitional rear toggle link with transitional New Model rounded edge, square face toggle knobs, rear link, serial number 100(52)B with identical Old Model dimensions and underside machining, using the Old Model coupling link. Also pictured is the final transitional version of the New Model toggle link assembly, serial number 10051B.

Also pictured is the final transitional version of the New Model toggle link assembly, serial number 10051B.

The 10051B and “100(52)B” are discussed in great detail in The Borchardt & Luger Automatic Pistols , a.k.a. TBLAP , a.k.a. TBLAP © 2010 & 2011 by ƚGörtz/Sturgess in Volume II, Chapter 10, Serial Numbers, on pages 633 & 634. © 2010 & 2011 by ƚGörtz/Sturgess in Volume II, Chapter 10, Serial Numbers, on pages 633 & 634.

This identically dimensioned serial number 100(52)B transitional rear link with rounded edge, square face toggle knobs with unique, single or one-piece, right side installed toggle knob claw, as part of a toggle link assembly consisting of a transitional 1904 navy serial number 2 middle link and navy proofed breechblock with narrow ear, hand stamped Geladen extractor [6] was fitted to a New Model short frame, chamber crested American Eagle receiver and 9 mm barrel. The New Model short frame, chamber crested American Eagle receiver and 9 mm barrel was successfully fitted to a

late Old Model Cartridge Counter, short frame with a dual leaf riband mainspring, [6] was fitted to a New Model short frame, chamber crested American Eagle receiver and 9 mm barrel. The New Model short frame, chamber crested American Eagle receiver and 9 mm barrel was successfully fitted to a

late Old Model Cartridge Counter, short frame with a dual leaf riband mainspring, which resulted in a configuration remarkedly similar to 10078B. which resulted in a configuration remarkedly similar to 10078B.

This same above exercise was attempted, using the same receiver/barrel/toggle link assembly, except replacing the late Old Model Cartridge Counter short frame with the transitional New Model short frame, serial number 10051B, converted from an Old Model, dual leaf riband mainspring to a true New Model coil mainspring and coupling link. The coupling was unsuccessful, suggesting a possibly, different New Model recoil conversion of the 10078B frame from the “later” 10000B final transitional New Model recoil spring conversions of 10051B, 10069B and 10070B , or simply a minor coupling link variation due to the one-off small batch, tool room assembly. , or simply a minor coupling link variation due to the one-off small batch, tool room assembly.

The unsuccessful mating may be also be attributed to a comment by Sturgess in TBLAP , VII, C10, page 634, Fig.10-39 text caption where he states that: the 100(52)B mainspring (coupling) link is a transitional pattern resembling the long, New Model type more than the short Old Model pattern, suggesting the 100(52)B rear link might work with the actual 10078B frame. , VII, C10, page 634, Fig.10-39 text caption where he states that: the 100(52)B mainspring (coupling) link is a transitional pattern resembling the long, New Model type more than the short Old Model pattern, suggesting the 100(52)B rear link might work with the actual 10078B frame.

10110.C.

10110.C., featured in a 1974 Guns & Ammo article is a transitional New Model 9 mm carbine presentation prototype article is a transitional New Model 9 mm carbine presentation prototype with a toggle link assembly similar to 10078B, of which the 10110.C. carbine also has a toggle link assembly, somewhat similar to the rear links of 100(52)B and 1904 transitional navy Luger S/N 79. with a toggle link assembly similar to 10078B, of which the 10110.C. carbine also has a toggle link assembly, somewhat similar to the rear links of 100(52)B and 1904 transitional navy Luger S/N 79. The underside rear links of 100(52)B and 79, both with one-piece toggle lock claws, except 10110.C., sharing similar machining, including near identical toggle knob underside edge knurling terminations and no 15-degree chamfer, straight wall channel edges. The underside rear links of 100(52)B and 79, both with one-piece toggle lock claws, except 10110.C., sharing similar machining, including near identical toggle knob underside edge knurling terminations and no 15-degree chamfer, straight wall channel edges. Click here for more Guns & Ammo 10110.C. detail pictures. Click here for more Guns & Ammo 10110.C. detail pictures.

5

The most significant difference in the toggle knob machining of 100(52)B and 79 vs. 10078B is that both were machined for and have a one-piece toggle lock claw, however, the 10110.C. machining is incomplete, as it has the inside wall 45-degree bevel, needed to clear the right-side frame rail anchor claw hook at full battery, however, it lacks the vertical cut or slot in the right-side edge toggle knob for the toggle lock claw. Per the 1974 Guns & Ammo article the 10110.C., right-side toggle knob locking claw has been removed as part of the original carbine assembly and the right-side frame rail toggle lock claw hook channel has been filled. article the 10110.C., right-side toggle knob locking claw has been removed as part of the original carbine assembly and the right-side frame rail toggle lock claw hook channel has been filled. The only currently available view of the 10110.C. toggle link assembly is of the underside, which shows only the bottom, purportedly “filled” exit point of the “removed” lower claw extension. The only currently available view of the 10110.C. toggle link assembly is of the underside, which shows only the bottom, purportedly “filled” exit point of the “removed” lower claw extension.

Since there is currently available no clear, straight-on, hi-res picture of the right-side toggle knob, only an angled, low resolution view, the claim of the toggle lock claw removal and the toggle knob

locking claw channel or slot being filled cannot be verified. The claim of the claw being removed and the vertical channel filled is put forth in the 1974 Guns & Ammo the claim of the toggle lock claw removal and the toggle knob

locking claw channel or slot being filled cannot be verified. The claim of the claw being removed and the vertical channel filled is put forth in the 1974 Guns & Ammo article, on page 67 article, on page 67 and later in The Borchardt & Luger Automatic Pistols and later in The Borchardt & Luger Automatic Pistols on page 257 on page 257 and in the page

258 Fig. 3-163 text caption, and in the page

258 Fig. 3-163 text caption, although, while mentioning the 10110.C. right-side toggle knob configuration, does not specifically state it originally had a one-piece toggle lock claw that was removed and the toggle knob channel filled. although, while mentioning the 10110.C. right-side toggle knob configuration, does not specifically state it originally had a one-piece toggle lock claw that was removed and the toggle knob channel filled.

The above assertions of the 10078B right side toggle knob, one-piece locking claw being removed and the channel being refilled and re-hatched, the edges re-fluted and the toggle knob locking claw anchor refilled is mostly resolved by close-up pictures of the right-side toggle knob surface and underside surface. To do all the changes described would require some form of re-bluing, which is not evident, furthermore, filling the toggle knob locking claw vertical, straight-line wall channel, one would expect to see evidence of seams, similar to the right side frame rail locking claw, hook solder fill. To do all the changes described would require some form of re-bluing, which is not evident, furthermore, filling the toggle knob locking claw vertical, straight-line wall channel, one would expect to see evidence of seams, similar to the right side frame rail locking claw, hook solder fill.

Pictured for comparison are the right-side toggle knobs of 10051B, 100(52)B and 10078B. As a matter of note, the breechblocks with narrow ear extractors discussed herein are New Model prototypes 10051B As a matter of note, the breechblocks with narrow ear extractors discussed herein are New Model prototypes 10051B , 10078B , 10078B , 10110.C. and transitional Navy prototype examples serial numbers 2 , 10110.C. and transitional Navy prototype examples serial numbers 2 and 79 and 79 . .

Additionally, the rear links of 100(52)B, 10078B and 10110.C. are different from 10051B, 10069B, 10070B rear links, in that they lack a subtle change, being that a 15-degree chamfer/angle, or 0.5 mm per the production drawing, was added to the toggle knob underside channel walls that fit/seat over the receiver forks at full battery, which continued into all future production Luger toggle knob underside channels. This was done to minimize any potential misalignment or galling, i.e. to guide the proper seating of the toggle knob channels on the receiver forks, resulting from the stronger, New Model coil mainspring system.

As stated above, the 100(52)B hybrid rear link toggle knob underside channel straight walls lack the 15-degree chamfer as do the M1903 French Chargé and 1904 transitional navy toggle knob underside channel walls, which suggests the 100(52)B rear link and circa 1903 French Chargé Lugers precede the transitional New Model 9 mm prototype Lugers. Pictured,

side-by-side are the undersides of new prototype manufacture, transitional toggle knobs of 10051B and 100(52)B, labeled to emphasize the differences, which suggests the 100(52)B rear link and circa 1903 French Chargé Lugers precede the transitional New Model 9 mm prototype Lugers. Pictured,

side-by-side are the undersides of new prototype manufacture, transitional toggle knobs of 10051B and 100(52)B, labeled to emphasize the differences, prior to the final production rear link toggle knob design. The 10078B toggle knob underside receiver fork channels are straight wall sides, similar to the three-surviving extant, final New Model 9 mm prototypes 10051B, 10069B, 10070B. prior to the final production rear link toggle knob design. The 10078B toggle knob underside receiver fork channels are straight wall sides, similar to the three-surviving extant, final New Model 9 mm prototypes 10051B, 10069B, 10070B.

The 10110.C. frame conversion is similar to 10078B, in that both frames were modified to New Model coil type mainsprings and the 10110.C. frame with its’ narrow or stepped trigger guard, is near identical to 10051B, 10069B and 10070B with New Model wide trigger, with the following exception, being the length of the 10010.C. carbine frame, which maintained the original 131 mm Old Model dimension length, with the only apparent reason being the extra 2mm materiel

or thickness in front of the take-down lever of the Old Model 131 mm length frame, allowing for sturdier attachment of the forestock tang, identical to the Old Model carbine.

The work involved in the conversion of an Old to New Model frame with New Model coil type mainspring is extensive, and unusual for 10110.C., in as much as the receiver used, appears to be a production, plain chambered, New Model, long frame receiver with New Model

ejector and sear bar leaf spring configuration, and a production, indented receiver ring chamber face, machined, at manufacture, to accept the New Model breechblock extractor tip, fitted with a retro Old/New Model toggle link assembly. fitted with a retro Old/New Model toggle link assembly.

6

These production, New Model, long frame receivers were first used on the Navy contract Lugers, circa 1905/06 as were available New Model 131 mm Swiss contract production frames, coincidently, replicating the 10110.C. frame machining. Regarding the receiver, TBLAP V1, C3, page 257 in the description of 10110.C., curiously, makes no mention of the receiver configuration, only to state that: The bolt (breechblock) and toggle are of production New Model pattern. V1, C3, page 257 in the description of 10110.C., curiously, makes no mention of the receiver configuration, only to state that: The bolt (breechblock) and toggle are of production New Model pattern.

TBLAP , VII, C3, page 257 Sturgess suggests the following regarding the protype features and the serial number assignment of 10110.C. It has a modified Old Model frame, as the other 100xxB New Model prototype pistols, with soldered in spring stays for the New Model coil main spring; machining for the main spring bell crank pivot pin; a soldered in block re-machined to form the trigger mounting recess, to modify the frame for the longer New Model trigger pivot block and the toggle latch in the frame right side rail replaced by a filler block. The bolt (breechblock) and toggle are of production New Model pattern, the corner radius of the checkered toggle finger grips being approximately 2 mm, rather than the more rounded 3 mm radius of the known New Model prototype pistols 10051B , VII, C3, page 257 Sturgess suggests the following regarding the protype features and the serial number assignment of 10110.C. It has a modified Old Model frame, as the other 100xxB New Model prototype pistols, with soldered in spring stays for the New Model coil main spring; machining for the main spring bell crank pivot pin; a soldered in block re-machined to form the trigger mounting recess, to modify the frame for the longer New Model trigger pivot block and the toggle latch in the frame right side rail replaced by a filler block. The bolt (breechblock) and toggle are of production New Model pattern, the corner radius of the checkered toggle finger grips being approximately 2 mm, rather than the more rounded 3 mm radius of the known New Model prototype pistols 10051B , 10069B , 10069B and 10070B. and 10070B.

Curiously, however, the underside of the right toggle finger grip of 10110.C., despite being externally of New Model pattern, has the wide 45º chamfer of an Old Model toggle, to provide clearance for a (nonexistent) frame hook for the (non-existent) toggle latch. 10110.C. also has no helper spring in the fore-end, the stronger coil main spring alone being sufficient to cope with the heavier recoiling parts. It would seem that this carbine probably has a serial number belonging to the 10xxxB prototype range (i.e. 10110B), with the "B" suffix changed to "C" to indicate Carabiner, as discussed above.

10130B

10130B is a Dutch test trials New Model transitional 9 mm Luger, although, mostly converted from an Old Model Luger frame, it was left out of the 10051B, 10069B and 10070B grouping because of some distinctive, advanced features. The most significant feature is the frame, while being similarly converted to a New Model coil mainspring from the Old Model Riband, flat leaf mainspring, the frame used was a late Old Model production 129 mm short frame, first used on the Cartridge Counter Lugers. Since the frame didn’t need shortening, the only other change was to the Old Model,

wide trigger guard and narrow trigger to the New Model narrow trigger guard and New Model wider trigger. This change to the trigger guard and frame-front contour is very apparent when 10130B is compared with 10051B. although, mostly converted from an Old Model Luger frame, it was left out of the 10051B, 10069B and 10070B grouping because of some distinctive, advanced features. The most significant feature is the frame, while being similarly converted to a New Model coil mainspring from the Old Model Riband, flat leaf mainspring, the frame used was a late Old Model production 129 mm short frame, first used on the Cartridge Counter Lugers. Since the frame didn’t need shortening, the only other change was to the Old Model,

wide trigger guard and narrow trigger to the New Model narrow trigger guard and New Model wider trigger. This change to the trigger guard and frame-front contour is very apparent when 10130B is compared with 10051B.

The other significant difference is the rear link used in 10130B, as it resembles the production link in the

following features, in that the toggle knob edges are more squared off in appearance, as in production, compared to the approximately 3-degree toggle knob rounded edges of 10051B, 10069B and 10070B. Additionally, the edges of the integral rear “T” section of the rear link are not beveled or softened like 10051B, 10069B and 10070B but are sharp like production. Additionally, the outside cam edges of the frame are not rounded or softened like 10051B, 10069B and 10070B, which is to be expected, as the frame used was a late Old Model, short frame production example. Additionally, the outside cam edges of the frame are not rounded or softened like 10051B, 10069B and 10070B, which is to be expected, as the frame used was a late Old Model, short frame production example.

As there are no available pictures of the receiver chamber face, it can be assumed the extractor cut is of the transitional New Model style, although it is possible that the circa 1905 delivered 10130B Dutch test trials Luger receiver chamber face is of a stepped, straight wall, as manufactured New Model production receiver, although it is possible that the circa 1905 delivered 10130B Dutch test trials Luger receiver chamber face is of a stepped, straight wall, as manufactured New Model production receiver, similar to the circa 1904 transitional navy Luger receiver interim chamber face extractor machining. Additionally, since the receiver used has the New Model, shortened Sear Bar spring and slot and New Model ejector, although it is not certain if the receiver used was a converted Old Model or as a New Model production receiver with Sear Bar and Ejector, which, if known would determine the type of receiver chamber face machining, transitional or production. similar to the circa 1904 transitional navy Luger receiver interim chamber face extractor machining. Additionally, since the receiver used has the New Model, shortened Sear Bar spring and slot and New Model ejector, although it is not certain if the receiver used was a converted Old Model or as a New Model production receiver with Sear Bar and Ejector, which, if known would determine the type of receiver chamber face machining, transitional or production.

8

As Sturgess suggests, that although the suffix letter “C” of 10110.C. was assigned, in this instance, to a carbine, the serial number could just as well have been assigned a B-suffix. Since the 10110.C. receiver appears to be manufactured as a New Model stepped ring, straight wall production chamber face as 10130B. The Dutch transitional prototype New Model Lugers are discussed in TBLAP , V1, C3, pages 297 – 298 in a section titled: The Hollandsch Model 101xxB New Model prototypes. In that section the above 10130B scenario is discussed with some assertions and conclusions similar to the above postulations. , V1, C3, pages 297 – 298 in a section titled: The Hollandsch Model 101xxB New Model prototypes. In that section the above 10130B scenario is discussed with some assertions and conclusions similar to the above postulations.

| | | |

| |

The Hollandsch Model 101xxB New Model prototypes

The last and major sub-group of 10xxxB prototypes are the ten 9 mm Dutch 1905 trials New Model pistols, ordered by the Dutch in December 1904 as "Dutch Model" pistols with the mainspring, breechblock & extractor etc. “altered following the newest arrangements” which were delivered to the Dutch Army for evaluation in August 1905, as the final delivery of their contract for 174 troop trials pistols. The balance of 164 pistols were all Old Models, 109 with 7.65/100 mm barrel delivered in March and July 1905 and 55 with 9/100 mm barrel delivered with the New Model prototypes in August. One example of the “Dutch Model”, sn 10130B, survives and sn 10127 is recorded in the trials report as being a Dutch Model, but was almost certainly in fact sn. 10127B. These pistols have been held by Dutch authors to be the origin of the New Model, and in particular the coil mainspring, which, it has been claimed, was designed "at the Dutch arsenal". Clearly these particular prototypes are, however, regardless of the simplistic view of their higher serial numbers demonstrating them chronologically to have been produced after the prototypes described above, of considerably later pattern and closer in some respects to the production New Model than the surviving earlier prototype examples already described, 10051B/69B/70B. and sn 10127 is recorded in the trials report as being a Dutch Model, but was almost certainly in fact sn. 10127B. These pistols have been held by Dutch authors to be the origin of the New Model, and in particular the coil mainspring, which, it has been claimed, was designed "at the Dutch arsenal". Clearly these particular prototypes are, however, regardless of the simplistic view of their higher serial numbers demonstrating them chronologically to have been produced after the prototypes described above, of considerably later pattern and closer in some respects to the production New Model than the surviving earlier prototype examples already described, 10051B/69B/70B.

These Dutch trials prototypes have the smaller, production pattern New Model toggle finger grip edge radius of 2 mm, rather than the more rounded 3 mm radius of the earlier prototypes, and the edges of the upper surface of the rear link behind the finger grips are only lightly broken to ~ 0.25 mm radius, like production New Model toggle links, rather than having the exaggerated 0.75 mm radius as do the earlier prototypes. The frames, although modified from Old Model components in the same fashion as the earlier prototypes, have the finalized short frame frontal profile, with the squared off horizontal flat before the trigger guard leaving a 2.6 mm thick web under the take down lever axle. The extractor is of the short ear (6.5 mm o/a width) prototype pattern with GELADEN stamped on the left side only. This pattern is interchangeable with that of prototype 10051B, The frames, although modified from Old Model components in the same fashion as the earlier prototypes, have the finalized short frame frontal profile, with the squared off horizontal flat before the trigger guard leaving a 2.6 mm thick web under the take down lever axle. The extractor is of the short ear (6.5 mm o/a width) prototype pattern with GELADEN stamped on the left side only. This pattern is interchangeable with that of prototype 10051B, but not the unique long/thick ear experimental pattern of 10069B & 70B: indeed, 10051B's (short ear) extractor is GELADEN marked and serial numbered 27 on its underside and may well have been exchanged for that originally fitted to 10127B. but not the unique long/thick ear experimental pattern of 10069B & 70B: indeed, 10051B's (short ear) extractor is GELADEN marked and serial numbered 27 on its underside and may well have been exchanged for that originally fitted to 10127B.

| |

| | | |

Back to 10078B and the “case” for a Case

If it is determined that the mechanical features of 10078B, is in all aspects a transitional/hybrid New Model Luger, that preceded the final 10051B, 10069B and 10070B transitional New Model Lugers, then it would be anachronistically inconsistent.

Additionally, with the 10000B series Lugers, other aspects or characteristics of authenticity are based on the examination of font style, size and placement of the serial numbers, which are unique to many of the B-series New Model variation prototype Lugers.

An example being the (1.5 mm) two-digit serial number placement of the transitional narrow ear extractor breechblocks, mostly located in the left side, lower channel recess. The breechblock serial number placement of 100(78)B is located higher, to the right of the extractor retention axle pin, typical of production. Additionally, the serial number font size of the transitional New Model 9 mm barrel, five-digit serial numbers is typically slightly smaller and tightly grouped than the frame B-suffix serial number applied to the cut-back frame, examples being 10051B, 10069B, 10070B. Additionally, the serial number font size of the transitional New Model 9 mm barrel, five-digit serial numbers is typically slightly smaller and tightly grouped than the frame B-suffix serial number applied to the cut-back frame, examples being 10051B, 10069B, 10070B.

9

Regarding the presentation status of 10078B, Kenyon in the 2005 Gun Report article states that the 10078B is a cased Graham h. Powell presentation. Kenyon pictures 10078B in a case, (Photo 5) which does appear authentic, along with a separate picture of a case cover (Photo 4) with a Graham h. Powell oval silver escutcheon, article states that the 10078B is a cased Graham h. Powell presentation. Kenyon pictures 10078B in a case, (Photo 5) which does appear authentic, along with a separate picture of a case cover (Photo 4) with a Graham h. Powell oval silver escutcheon, unfortunately, that particular case cover and escutcheon unfortunately, that particular case cover and escutcheon is associated with the only known, genuine and authenticated Graham h. Powell presentation Old Model 4¾-inch barrel 30 Cal, gold inlaid G.H.P. chamber crested Luger. is associated with the only known, genuine and authenticated Graham h. Powell presentation Old Model 4¾-inch barrel 30 Cal, gold inlaid G.H.P. chamber crested Luger.

Which, coincidently, is also featured in Kenyon’s 1991 publication Luger: The Multi-National Pistol on pages 50 and 51, described by Kenyon as a Graham h. Powell cased presentation, on pages 50 and 51, described by Kenyon as a Graham h. Powell cased presentation, where, in actuality is pictured a cased presentation Luger, though not of Graham h. Powell, but belonging to a Colonel Theodore A. Bingham where, in actuality is pictured a cased presentation Luger, though not of Graham h. Powell, but belonging to a Colonel Theodore A. Bingham [7] and where, interestingly, on the opposite page 50 he pictures the unidentified 10078B frame only, probably extracted/cropped from the 1983 man at ARMS [7] and where, interestingly, on the opposite page 50 he pictures the unidentified 10078B frame only, probably extracted/cropped from the 1983 man at ARMS article, stating simply: Side view of Powell Cartridge Indicator Device (note four cartridges loaded), inexplicably, with no mention of serial number or explanation. article, stating simply: Side view of Powell Cartridge Indicator Device (note four cartridges loaded), inexplicably, with no mention of serial number or explanation.

Based solely on the commonality of the style and application of the gold inlaid chamber crests of both the Theodore A. Bingham (TAB) and Graham h. Powell (GHP) examples, that the chamber crests of both 4¾-inch 30 Cal, cased presentation Lugers were made by the same craftsman and that they were presented in the same, circa 1900 – 1901 time-frame. that the chamber crests of both 4¾-inch 30 Cal, cased presentation Lugers were made by the same craftsman and that they were presented in the same, circa 1900 – 1901 time-frame.

| | | |

| |

Extraordinary "Col. Theodore Bingham" Cased and Gold Inlaid Presentation "First Available" DWM Model 1900 Commercial Luger Pistol Serial Number 2001.

Description: This is a beautiful, totally

original example of a very rare and very early, one of a kind, presentation DWM

Model 1900 Commercial Luger pistol that was presented to Colonel Theodore A. Bingham who was

Superintendent of Buildings and Grounds in the District of Columbia at that

time. It is theorized that this wonderful Luger was presented to him

on behalf of the DWM factory by Hans Tauscher, the noted German spy, saboteur,

and sales agent for the DWM Company. Tauscher started working for the DWM

factory as a sales agent in the U.S. in 1897/98 in New York and also appears to

have been in the States earlier in that decade. He continued to work as a sales

agent for the DWM factory and the German government in the U.S. until he was

charged with of being part of a spy ring under the control of Captain von

Papen. He was not convicted but was sent back to Europe. He returned to the

U.S. before WWII. Von Papen was instrumental in getting Adolf Hitler appointed

as Reich Chancellor and eventually became a general in the German Army during

WWII. Theodore A. Bingham graduated from the West Point Military Academy in

1879 and received a commission as second lieutenant. Between 1879 and 1890, he

served in various capacities as an engineering officer and as a military attaché

in Berlin and Rome. He served as superintendent of the public buildings and

grounds at Washington, D.C. from 1897 to 1901 with the rank of colonel. Later,

from 1906 to 1909, he was the New York City Police Commissioner. The position

of Superintendent of Buildings and Grounds in Washington, D.C. may seem to be a

relatively simple appointment today, but at that time Tauscher may have

befriended him using this presentation Luger to become acquainted with many

high ranking military contacts in Washington. This naturally would have helped

him when the testing of the .45 ACP pistol was conducted in 1907. A full tour

of all the buildings and grounds may have also helped him if he planned to

carry out some kind of saboteur work later on behalf of the German government.

While not documentation is available to substantiate this latter intent, it is

easy to jump to these potentially damning conjectures! The pistol itself is an

extremely early example that is in all probability the very first DWM Model

1900 Luger manufactured as serial numbers are reported to have begun at 2001 after the 2,000-gun Swiss 1900 Luger contract was filled.

Obviously, this a very special and very rare early Luger pistol even without

the historical connections. The pistol is from the famed Ralph Shattuck

Collection and is a beautiful and all original. It has the large intertwined

gold inlaid initials "TAB" (Theodore A. Bingham) roll marked over the

chamber It is theorized that this wonderful Luger was presented to him

on behalf of the DWM factory by Hans Tauscher, the noted German spy, saboteur,

and sales agent for the DWM Company. Tauscher started working for the DWM

factory as a sales agent in the U.S. in 1897/98 in New York and also appears to

have been in the States earlier in that decade. He continued to work as a sales

agent for the DWM factory and the German government in the U.S. until he was

charged with of being part of a spy ring under the control of Captain von

Papen. He was not convicted but was sent back to Europe. He returned to the

U.S. before WWII. Von Papen was instrumental in getting Adolf Hitler appointed

as Reich Chancellor and eventually became a general in the German Army during

WWII. Theodore A. Bingham graduated from the West Point Military Academy in

1879 and received a commission as second lieutenant. Between 1879 and 1890, he

served in various capacities as an engineering officer and as a military attaché

in Berlin and Rome. He served as superintendent of the public buildings and

grounds at Washington, D.C. from 1897 to 1901 with the rank of colonel. Later,

from 1906 to 1909, he was the New York City Police Commissioner. The position

of Superintendent of Buildings and Grounds in Washington, D.C. may seem to be a

relatively simple appointment today, but at that time Tauscher may have

befriended him using this presentation Luger to become acquainted with many

high ranking military contacts in Washington. This naturally would have helped

him when the testing of the .45 ACP pistol was conducted in 1907. A full tour

of all the buildings and grounds may have also helped him if he planned to

carry out some kind of saboteur work later on behalf of the German government.

While not documentation is available to substantiate this latter intent, it is

easy to jump to these potentially damning conjectures! The pistol itself is an

extremely early example that is in all probability the very first DWM Model

1900 Luger manufactured as serial numbers are reported to have begun at 2001 after the 2,000-gun Swiss 1900 Luger contract was filled.

Obviously, this a very special and very rare early Luger pistol even without

the historical connections. The pistol is from the famed Ralph Shattuck

Collection and is a beautiful and all original. It has the large intertwined

gold inlaid initials "TAB" (Theodore A. Bingham) roll marked over the

chamber area and the standard DWM markings on the front toggle. This

pistol has the early features such as the early long frame with flat recoil

spring, dished toggles with toggle lock, recessed breechblock, 4¾-inch

tapered barrel, grip safety, and first type safety with the bright polished

lower safety area. Interestingly, this pistol has the early second type safety

lever with the slightly higher raised thumb area that is checkered and not

serrated, and the left side of the barrel has a small Swiss Cross firing proof;

both of these features were used on the first Swiss contract Lugers and clearly

indicate that DWM reused left over contract parts in following commercial

contracts. It has the correct commercial style serial number placement with serial number "2001"

stamped on the front of the frame and underside of the barrel area and the standard DWM markings on the front toggle. This

pistol has the early features such as the early long frame with flat recoil

spring, dished toggles with toggle lock, recessed breechblock, 4¾-inch

tapered barrel, grip safety, and first type safety with the bright polished

lower safety area. Interestingly, this pistol has the early second type safety

lever with the slightly higher raised thumb area that is checkered and not

serrated, and the left side of the barrel has a small Swiss Cross firing proof;

both of these features were used on the first Swiss contract Lugers and clearly

indicate that DWM reused left over contract parts in following commercial

contracts. It has the correct commercial style serial number placement with serial number "2001"

stamped on the front of the frame and underside of the barrel and

the last two digits on the trigger, side plate, breechblock and toggle train.

The takedown lever has the serial number stamped on the right side, raised dome

area, like the later U.S. Test Eagle Lugers. This wonderful and historic Luger

is complete with the original DWM factory black leatherette storage/carrying

case. On top of the lid is a

small oval 1¾-inch x 2¼-inch silver name plate that is marked

"Colonel/Theodore/A. Bingham". and

the last two digits on the trigger, side plate, breechblock and toggle train.

The takedown lever has the serial number stamped on the right side, raised dome

area, like the later U.S. Test Eagle Lugers. This wonderful and historic Luger

is complete with the original DWM factory black leatherette storage/carrying

case. On top of the lid is a

small oval 1¾-inch x 2¼-inch silver name plate that is marked

"Colonel/Theodore/A. Bingham". The case contains two

original wooden base commercial magazines, a brass cleaning rod with the steel

oiler/handle, a takedown pin-punch and two smaller tins; one for lubrication

grease and the other one a small oiler, both with leather covers. The Luger has

a beautiful rust blued finish, straw colored smaller parts, and checkered

walnut grips. The case contains two

original wooden base commercial magazines, a brass cleaning rod with the steel

oiler/handle, a takedown pin-punch and two smaller tins; one for lubrication

grease and the other one a small oiler, both with leather covers. The Luger has

a beautiful rust blued finish, straw colored smaller parts, and checkered

walnut grips.

Condition: Excellent plus with 99% of the bright original blue finish overall with just a hint of edge wear and a small spot of blue loss on the very lower front grip strap edge. The smaller parts retain 95% plus of their vivid original straw colors with slightly less on the trigger and a little more on the takedown lever. The grips are also in excellent plus condition with nice distinct checkering overall and the left side showing a few minor nicks in the checkered diamonds at the top rear edge. The case is in fine condition overall with a nice black leatherette cover on the outside showing light wear around the edges and most of the slightly faded original green felt interior lining complete with a little separation at the top. The felt needs to be cleaned or vacuumed as it has been in storage for a considerable number of years. Really a fabulous, super rare all original early DWM Model 1900 Presentation Luger pistol with great historical significance!

| |

| | | |

Also, the no GERMANY export stamped 6054 serial number of the cased GHP Luger, being so close to the 1900 U.S. Test Eagle Luger serial number range, is not a coincidence, but supports the notion of credibility or authenticity of the only verified Powell cased presentation Luger.[8] It is interesting to note that a table of identified M1900 U.S. Army Test Eagle Lugers in U.S. Military Automatic Pistols 1894 – 1920 © 1993 by E. Scott Meadows on page 384 identifies the lowest known example, being serial number 6009. © 1993 by E. Scott Meadows on page 384 identifies the lowest known example, being serial number 6009.

Regarding the Colonel Theodore A. Bingham (TAB) cased presentation Luger, serial number 2001, being the first commercial Luger after the 2,000-gun Swiss 1900 Luger contract was filled, is not the only cased M1900 Luger with a very low 2000 range serial number as DWM serial number 2125, American Eagle chamber crested Luger with an identically fitted case as the TAB and GHP presentation cases, exists as part of the Land of Borchardt collection, pictured with a computer-generated LOB oval, silver escutcheon on the case cover.

TBLAP VII, C19, presentation case comments: Although the standard green baize lined wood framed cases, externally finished with fine grained black calf-skin and nickel-plated fittings, were equipped with an oval German silver blank escutcheon on the lid, they were not presentation cases, the escutcheon being normal European trade practice then, and for many years before and after, to allow the owner to mark his property with his name or initials. Later DWM supplied cases may be found without this oval escutcheon which, however, seems universal on original Loewe cases.

The LOB pictured case is identical, internally and externally to the Graham h. Powell and Theodore A. Bingham presentation cased Lugers and additionally the Colonel Theodore A. Bingham case pictured case is identical, internally and externally to the Graham h. Powell and Theodore A. Bingham presentation cased Lugers and additionally the Colonel Theodore A. Bingham case is fitted with a M1900 Luger with a four-digit serial number 2001 is fitted with a M1900 Luger with a four-digit serial number 2001 and the LOB case and the LOB case is fitted with a very early M1900 American Eagle Luger in the same low four-digit serial number range, being 2125. is fitted with a very early M1900 American Eagle Luger in the same low four-digit serial number range, being 2125. The only difference in these three cases, which were constructed and fitted in the same 1900 – 1901 time-frame, is that the LOB case cover lacks an oval, silver escutcheon. The only difference in these three cases, which were constructed and fitted in the same 1900 – 1901 time-frame, is that the LOB case cover lacks an oval, silver escutcheon.

Contrary to Kenyon’s 2005 Gun Report article assertions of 10078B as a Graham h. Powell cased presentation, the 1983 man at ARMS article assertions of 10078B as a Graham h. Powell cased presentation, the 1983 man at ARMS article author on page 22 states otherwise, that the stand-alone, 4-inch barrel, 9 mm 10078B New Model transitional Luger says that: At that time the pistol surfaced in the late 1970’s it was encased in a soft leather glove, not a holster. The glove appears to be factory original. Additionally, it was accompanied, only with three Cartridge Counter magazines, and to reiterate, with no mention of a case. Although, as to how 10078B survived for more than a century, together with “two detached” Cartridge Counter magazines, unless they were in the “soft leather glove”, is amazing. article author on page 22 states otherwise, that the stand-alone, 4-inch barrel, 9 mm 10078B New Model transitional Luger says that: At that time the pistol surfaced in the late 1970’s it was encased in a soft leather glove, not a holster. The glove appears to be factory original. Additionally, it was accompanied, only with three Cartridge Counter magazines, and to reiterate, with no mention of a case. Although, as to how 10078B survived for more than a century, together with “two detached” Cartridge Counter magazines, unless they were in the “soft leather glove”, is amazing.

Interestingly, the mention of three, in this instance, Cartridge Counter magazines, is what one would expect to find with an early cased Luger, one in the grip and two spares in the case. Since 10078B, twenty-two years later in 2005 is pictured in a case, for reasons unknown, a case was not mentioned, i.e. missing in 1983, reappearing in the 2005 Gun Report article, in a photograph, conveniently picturing the cropped case and contents with a “separate” picture of the wrong cover, despite the Graham h. Powell inscribed oval silver escutcheon. article, in a photograph, conveniently picturing the cropped case and contents with a “separate” picture of the wrong cover, despite the Graham h. Powell inscribed oval silver escutcheon.

Additionally, the Kenyon article picture of the cropped case containing 10078B shows that the case, when closed, is secured with two unlockable clasps only and lacks a keyed lock, which is present on the three pictured lockable cases, being the circa 1907 Graham h. Powell presentation case, the Theodore A. Bingham presentation case, and the non-presentation case LOB example. which is present on the three pictured lockable cases, being the circa 1907 Graham h. Powell presentation case, the Theodore A. Bingham presentation case, and the non-presentation case LOB example. The lack of a keyed lock and a slightly different compartment partition configuration and accessories placement of the 10078B case vs. the three cited, identically configured/constructed 1900 – 1901 DWM factory supplied cases suggests, at a minimum the 10078B case is not DWM factory supplied and of a later time period, different, possible non-European manufacture. The lack of a keyed lock and a slightly different compartment partition configuration and accessories placement of the 10078B case vs. the three cited, identically configured/constructed 1900 – 1901 DWM factory supplied cases suggests, at a minimum the 10078B case is not DWM factory supplied and of a later time period, different, possible non-European manufacture.

Furthermore, based on extrapolated dimensions of the loading tool/screwdriver accessory in the 10078B case is of the first pattern. This is based on information presented in TBLAP, Volume III, Accessories, Fig. 19-193 presentation screwdrivers This is based on information presented in TBLAP, Volume III, Accessories, Fig. 19-193 presentation screwdrivers and descriptive text on pages 1315-1316 that the 10078B 50 mm in length loading tool/screwdriver is not the first pattern, 54.5 mm length loading tool/screwdriver associated or found in all noted, early 1900 – 1901 DWM factory supplied presentation cases. and descriptive text on pages 1315-1316 that the 10078B 50 mm in length loading tool/screwdriver is not the first pattern, 54.5 mm length loading tool/screwdriver associated or found in all noted, early 1900 – 1901 DWM factory supplied presentation cases.