buttons

Jagdkarabiner „Parabellum“

|

|

Abnehmen des Vorderschaftes. – Zunächst den Schieber mit dem Fingernagel soweit tunlich von links nach rechts eindrücken, dann rechts bis zum Anschlag herausziehen, worauf der Vorderschaft von seiner Verbindungsschiene am Griffstück nach abwärts entfernt wird. Alles weitere Zerlegen geschieht nach Vorschrift der Beschreibung der Pistole „Parabellum“ von Seite 27 an. b) Zusammensetzen

Geschieht in umgekehrter Folge des Zerlegens, von Seite 29 der Beschreibung an; ferner das Anbringen des Vorderschaftes durch passendes Andrücken von unten, sodann feststellen durch Eindrücken des Schiebers von rechts nach links. |

English

|

Dismantling of the Fore-end. – To take off the front forearm one must press in the slide with a fingernail from left to right as much as necessary, while then holding in the firing position, after this the front forearm is removed from its connecting rail. The further dismantling is carried out according to the description of the “Parabellum” pistol starting on page 27. b) Assembling

Follow in reverse order the stripping of page 29 of the instructions; in addition, the attachment of the fore-end through appropriate pressing in from underneath, so that it can be fixed by pushing through the slider from right-to-left. |

Another testament of German attention to detail is an interesting change or modification to the production forestock with the addition of an elongated slot or channel in the wood where it cradles the frame/trigger guard underside. The slot accommodates the frame take-down lever locking bolt retention spring round termination protrusion, immediately below

the take-down lever locking bolt forward axle on the bottom of the frame.

The slot accommodates the frame take-down lever locking bolt retention spring round termination protrusion, immediately below

the take-down lever locking bolt forward axle on the bottom of the frame. This elongated slot was added to allow front-to-rear tolerance for proper seating, i.e. minimize any interference and allow proper seating of the forestock to the frame/trigger guard underside as a result of less than a perfectly aligned reattachment of the forestock. This elongated channel is missing in the Carbine 58 preproduction prototype forestock where there exists a forced seating indent impressed by the take-down lever tension spring frame underside protrusion.

This elongated slot was added to allow front-to-rear tolerance for proper seating, i.e. minimize any interference and allow proper seating of the forestock to the frame/trigger guard underside as a result of less than a perfectly aligned reattachment of the forestock. This elongated channel is missing in the Carbine 58 preproduction prototype forestock where there exists a forced seating indent impressed by the take-down lever tension spring frame underside protrusion. In addition to all production carbine Luger forestocks, this channel is present in the transitional carbine forestocks of 9102C, 9103C, 77.

In addition to all production carbine Luger forestocks, this channel is present in the transitional carbine forestocks of 9102C, 9103C, 77. The presence of these elongated slots or channels further suggests these transitional carbines came after the two-digit preproduction prototype carbines.

The presence of these elongated slots or channels further suggests these transitional carbines came after the two-digit preproduction prototype carbines.

The Luger Carbine Forestock Underside Cavity

For the sake of simplicity, ignoring the serial number sequence, which in this case is no indicator, the design evolution of the production forestock, specifically the interior cavity consists of three stages, identified by surviving examples, including the first preproduction prototype hunting carbines with the 11¾-inch, slim tapered barrel and unique forestock sliding retaining wedge configuration.

The first pictured Carbine 58 with rear link mounted, 5-position 1-3-5 adjustable tangent leaf sight, forestock example represents one of the first preproduction prototype example extant carbine forestocks made by DWM. While the forward section of the underside cavity has a curious, purpose unknown rectangular cut-out, there is no plunger assist device. The underside cavity walls conform to the first carbine slim tapered barrel

with rear link mounted, 5-position 1-3-5 adjustable tangent leaf sight, forestock example represents one of the first preproduction prototype example extant carbine forestocks made by DWM. While the forward section of the underside cavity has a curious, purpose unknown rectangular cut-out, there is no plunger assist device. The underside cavity walls conform to the first carbine slim tapered barrel , similar to the 4¾-inch, old model style 1900 slim tapered barrel with production type sight band/block/blade configuration, except being 11¾-inches long.

, similar to the 4¾-inch, old model style 1900 slim tapered barrel with production type sight band/block/blade configuration, except being 11¾-inches long.

The second pictured carbine 77 forestock example features the addition of the plunger recoil assist device with the interior cavity walls contoured to fit the interim production thick wall carbine barrel, without the 4-position, 100-300M rear barrel mounted adjustable sight, but with the final ramped front sight block and blade.

forestock example features the addition of the plunger recoil assist device with the interior cavity walls contoured to fit the interim production thick wall carbine barrel, without the 4-position, 100-300M rear barrel mounted adjustable sight, but with the final ramped front sight block and blade. This hybrid configuration is used with the rear link mounted, 5-position 1-3-5 adjustable tangent leaf sight.

This hybrid configuration is used with the rear link mounted, 5-position 1-3-5 adjustable tangent leaf sight.

The third pictured is carbine 9103.C. with the first production type, thicker wall barrel, but with simple front sight block and blade without a sight band. Since the 9103.C. carbine with the production type thicker barrel, except for the absence of a rear mounted, 4-position 100-300M sight is identical to the final production barrel, the 9103.C. forestock underside cavity

Since the 9103.C. carbine with the production type thicker barrel, except for the absence of a rear mounted, 4-position 100-300M sight is identical to the final production barrel, the 9103.C. forestock underside cavity , is also identical to the first pictured carbine 77 example

, is also identical to the first pictured carbine 77 example .

.

The fourth pictured carbine 9102.C. example also features the added plunger recoil assist device with interior cavity contour conforming to the final design carbine thick wall tapered barrel with the ramped front sight block and blade and with the final production, 4-position, 100-300M adjustable rear barrel mounted sight. Since the 4-position sight integral block is sleeved to the barrel, it has a slightly larger tapered diameter

also features the added plunger recoil assist device with interior cavity contour conforming to the final design carbine thick wall tapered barrel with the ramped front sight block and blade and with the final production, 4-position, 100-300M adjustable rear barrel mounted sight. Since the 4-position sight integral block is sleeved to the barrel, it has a slightly larger tapered diameter , therefore, the forestock interior cavity had to be slightly widened at the barrel/receiver interface to accommodate the wider tapered diameter rear sight, barrel sleeved configuration

, therefore, the forestock interior cavity had to be slightly widened at the barrel/receiver interface to accommodate the wider tapered diameter rear sight, barrel sleeved configuration .

.

The fifth pictured is a 2-sided view of a circa 1902 production Luger hunting carbine with the final production forestock underside cavity configuration

with the final production forestock underside cavity configuration .

.

The Forestock Tang

Another change for production was to the rectangular opening slot in the frame extension tang, which was enlarged from the preproduction Carbine 58

tang slot of 10.2mm in length x 2.3mm in height to 14mm in length x 2.7mm in height. The actual new horizontal opening tang length is 11.5mm as the wider dimension of 14mm is measured at the edge opening because of the chamfering of each end of the opening on both sides. This was done to act as a guide, probably in conjunction with the above stated modification, if the wedge and forestock were not perfectly aligned with the tang slot while inserting the wedge. Pictured are the preproduction prototype tang vs. the production tang .

.

Another subtle, but interesting difference between the preproduction prototype and production tang, is the location of the “jig” or anchor screw that goes through the tang and the front of the frame. In the preproduction tang the screw entrance is located just forward of the take-down lever locking bolt spring, screwed in at a rearward angle, terminating in the front area of the frame take-down lever locking bolt spindle circular wall. This is the shortest section of the frame, being only 4 mm thick, allowing little support. The location of the tang, slightly longer screw in the production carbine frame entrance location was moved lower and to the rear of the take-down lever locking bolt spring with the screw terminating in the rear frame lug well, rear and lower of the take-down lever locking bolt circular wall, thereby slightly increasing the depth of the screw and subsequent increased anchor strength. Pictured is the exit or termination of the tang securing screw in the preproduction frame forward lug well take down lever spindle wall as compared to

the typical production tang/frame screw exit location shown in a left side profile cross section X-ray.

as compared to

the typical production tang/frame screw exit location shown in a left side profile cross section X-ray.

The Barrel

The standard M1900 production Lugers with the 4¾-inch 30 Cal, slim tapered barrels used an old model dual Riband recoil spring, while the 7-inch Chilean 2-4-6, six-position rear sight required the addition of a stronger Riband mainspring leaf and, one would think, most certainly that the preproduction prototype 1-3-5, five-position graduated rear link sight carbine with 11¾-inch barrel would also require a stronger recoil spring, however, it uses a standard thickness M1900 dual leaf Riband recoil spring.

The standard production M1900 4¾-inch barrel/receiver weighs 9.3 ounces or 264 grams, the 7-inch Chilean barrel/receiver weighs 10.6 ounces or 300 grams and is 14% heavier than the standard 4¾-inch barrel receiver. The 11¾-inch slim tapered barrel/receiver of the subject preproduction prototype Carbine 58

weighs 15 ounces or 424 grams and is 61% heavier than the standard 4¾-inch barrel receiver. The final production 11¾-inch barrel/receiver weighs a whopping 20.1 ounces or 570 grams and is 116% heavier than the standard 4¾-inch barrel/receiver. Coincidently, the Carbine 58 barrel/receiver weight is 91% heavier than the 7-inch Chilean 2-4-6 carbine barrel/receiver, which to compensate for the longer, heavier Chilean barrel DWM installed a stronger Riband recoil spring leaf in conjunction with a heaver load cartridge. Pictured are the various length old model 30 Cal slim tapered barrels/receivers with weights and dimensions.

It should be noted that in TBLAP Volume I, Chapter 3 – Development of the Parabellum Pistol, page 243 states that the weight of the recoiling assembly of the barrel/receiver/bolt and toggle with

multi-position sight of the prototype carbine is 615 g. In this article the barrel/receiver weight of Carbine 58 was, minus the toggle link assembly and rear axle pin, to be exactly 424 g.

page 243 states that the weight of the recoiling assembly of the barrel/receiver/bolt and toggle with

multi-position sight of the prototype carbine is 615 g. In this article the barrel/receiver weight of Carbine 58 was, minus the toggle link assembly and rear axle pin, to be exactly 424 g. The Carbine 58, 1-3-5 graduated

toggle link assembly

The Carbine 58, 1-3-5 graduated

toggle link assembly with rear axle pin weighs exactly 176 g for a total assembly weight of 600 g, 15 g less than stated in TBLAP. It is also interesting that the weight of the GL presentation Chilean “type” GL Presentation Carbine 10005, 2-4-6 graduated toggle link assembly with rear axle pin weighs exactly 178 g, being 2 g heavier.

with rear axle pin weighs exactly 176 g for a total assembly weight of 600 g, 15 g less than stated in TBLAP. It is also interesting that the weight of the GL presentation Chilean “type” GL Presentation Carbine 10005, 2-4-6 graduated toggle link assembly with rear axle pin weighs exactly 178 g, being 2 g heavier.

One would think, as stated above that the preproduction prototype two-digit serial number hunting carbines, especially the very early, identified by serial number carbines (serial numbers 35 and 58) without the forestock installed plunger assist device certainly required, at a minimum, a stronger Riband main spring and most importantly a hotter cartridge. It is well established that the commercially offered production Luger hunting carbine with its massive barrel required the packaging of special hotter load ammunition sold to the public. It has also been established that special ammunition was required for the Chilean Carbine 2-4-6, six-position rear link integral sight Luger, although no DWM ammunition packaging for the small batch manufacture Chilean carbine Lugers has ever been identified, which is to be expected for a limited prototype series as was the very limited first preproduction prototype 11¾-inch slim tapered barrel carbines.

Sturgess comments in TBLAP, Volume I, Chapter 3 – Development of the Parabellum Pistol, page 222, on early recoil springs and carbine ammunition: Shortly after this change the first stocked pistols with 175 mm long barrel and variable range sight, as described below, were developed for Chilean Army trials and, since specifically adapted to fire ammunition with a heavier charge (to be later marketed as the well-known blackened case carbine load, DWM 471A), they, as described in the factory literature, were fitted with yet stronger springs. These were of unequal leaf thickness, the main, front leaf with the hook at its upper end being approximately 1.15 mm thick in the body, tapering to 0.75 mm thick at the top, the rear, subsidiary leaf having a uniform thickness of 0.75 mm. The early (two-digit) prototype and transitional carbines retained the original thin spring leaves. However, the production carbines in the main have the equal, thicker 0.85 mm leaves.

Regarding the above Sturgess statement in TBLAP that the early preproduction prototype and transitional carbines retained the original thin Riband recoil springs is interesting and maybe correct for some of the transitional carbines with the forestock added recoil spring loaded plunger assist device, although not transitional carbine 77 as it definitely utilized a larger, one of two leaf flat mainsprings, which is very interesting as the Carbine 77 forestock incorporates the additional spring plunger assist

which is very interesting as the Carbine 77 forestock incorporates the additional spring plunger assist . However, the use of M1900 production equal thickness flat mainsprings, if true for the only five known preproduction prototype carbines with slim tapered barrels, in chronological order, the first being carbine 35

. However, the use of M1900 production equal thickness flat mainsprings, if true for the only five known preproduction prototype carbines with slim tapered barrels, in chronological order, the first being carbine 35 pictured in a 2002 Gun Report article

pictured in a 2002 Gun Report article and Carbine 58, first pictured in 1959 Luger Variations

and Carbine 58, first pictured in 1959 Luger Variations and the third being carbine 9103C pictured in 1971 German Pistols and Revolvers 1871-1945

and the third being carbine 9103C pictured in 1971 German Pistols and Revolvers 1871-1945 and the fourth in 2010-2011 TBLAP Fig. 3-142,

and the fourth in 2010-2011 TBLAP Fig. 3-142, with the fourth example unidentified and without any other information, also purportedly, without the forestock assist recoil plunger, all four would perform poorly, even with a heavier charge cartridge. If they indeed all had original, equal thickness thin recoil springs, additionally suggests that the early preproduction two-digit serial numbered preproduction prototype carbines, including carbines 35 and 58 may have been manufactured before the 10000 serial number series Chilean Carbine second issue thumb safety prototypes. The possibility that the preproduction prototype hunting carbines preceded the 10000 serial number Chilean series is reinforced by the use of a first issue thumb safety with the TBLAP Fig. 3-142 unidentified preproduction prototype Luger carbine rig and Carbine 35.

with the fourth example unidentified and without any other information, also purportedly, without the forestock assist recoil plunger, all four would perform poorly, even with a heavier charge cartridge. If they indeed all had original, equal thickness thin recoil springs, additionally suggests that the early preproduction two-digit serial numbered preproduction prototype carbines, including carbines 35 and 58 may have been manufactured before the 10000 serial number series Chilean Carbine second issue thumb safety prototypes. The possibility that the preproduction prototype hunting carbines preceded the 10000 serial number Chilean series is reinforced by the use of a first issue thumb safety with the TBLAP Fig. 3-142 unidentified preproduction prototype Luger carbine rig and Carbine 35.

Additionally, regarding the use of the standard dual Riband recoil spring used in the preproduction prototype carbine, a reasonable conclusion is that the carbine, as stated earlier, was introduced before the Chilean trials carbines created for the Chilean military. The designer(s) of the Luger hunting carbine, very soon came to the conclusion that due to the extended length and added weight of the carbine barrel, that in order to solve the problem of weak return to battery after full recoil, it was necessary to add a forestock spring loaded plunger assist, while curiously keeping the M1900 standard dual Riband recoil springs.

It is not completely certain if a hotter load cartridge was used with the first hunting carbines, with or without the added forestock spring loaded plunger assist. It is also probable that the frame used on the first preproduction prototype carbines, specifically with the 11¾-inch long slim tapered barrels, used a standard M1900 frame with the push-button stock-lug machined into the lower rear gripstrap, leaving a knife edge, while the later Chilean frames with the push-button type stock-lugs utilized a completely new forging, also with a knife edge.

Interestingly, the Chilean military carbines with their 7-inch (175mm) slim tapered barrels, almost 5-inches shorter and lighter than the preproduction prototype carbine, still necessitated the use of a heaver mainspring, along with a hotter cartridge. Since the Chilean trials carbines lacked a forestock to add a spring loaded plunger assist, the problem of a weak return to battery was solved by adding the stronger recoil leaf spring. For more information on the Chilean prototypes click here.

The subject circa 1901 preproduction prototype Luger Carbine 58 was developed and manufactured as a hunting carbine for eventual commercial sale. This preceded the later introduction of the production carbine and one would assume that it also required special ammunition that was not yet available to the public. Therefore, this dismisses any possibility that Carbine 58 was originally assembled and deliberately not proofed by DWM for commercial sales or a special order per customer request, and as such should be classified as an “in-house” experimental preproduction prototype carbine. This is not to say that Carbine 58 was not eventually excessed by DWM, being sold commercially, possibly after the introduction of the production carbine when the higher load carbine ammunition was generally available.

A perfect example of one such “in-house” preproduction prototype Luger hunting carbine is the one owned by President Theodore Roosevelt, a cased presentation carbine, acquired by Theodore Roosevelt [5] after becoming President in September 1901. A surviving two-page letter dated July 2, 1902 from Frank H. Phipps, Lieut. Colonel, Ordnance Dept. directed to the Chief of Ordnance (Crozier) describing the status of the President’s carbine recently sent to the Springfield Armory

[5] after becoming President in September 1901. A surviving two-page letter dated July 2, 1902 from Frank H. Phipps, Lieut. Colonel, Ordnance Dept. directed to the Chief of Ordnance (Crozier) describing the status of the President’s carbine recently sent to the Springfield Armory to be examined and tested for changes to be made in the sight. It was determined after the Springfield Armory test firing the carbine with the 30 Cal Luger (M1900 Test Eagle) ammunition on hand - did not produce enough recoil to make the carbine work automatically. The army, after much effort and delay, managed to get 50 rounds of carbine ammunition from Tauscher and resumed the test firing to correct the sighting issues, however, before the sighting issues were resolved the 50 rounds of carbine ammunition were soon expended.

to be examined and tested for changes to be made in the sight. It was determined after the Springfield Armory test firing the carbine with the 30 Cal Luger (M1900 Test Eagle) ammunition on hand - did not produce enough recoil to make the carbine work automatically. The army, after much effort and delay, managed to get 50 rounds of carbine ammunition from Tauscher and resumed the test firing to correct the sighting issues, however, before the sighting issues were resolved the 50 rounds of carbine ammunition were soon expended.

The army then approached the Union Metallic Cartridge Company, asking if it made any. Frank H. Phipps then states in the letter: If it does not, I do not know of any place in this country where they can be bought. Additionally, stating that although the cartridges for this carbine are of about the same length, the cartridges for this carbine has a powder charge weighing 1.45 grains more than that of the regular pistol cartridges, and the cartridge shell is crimped more into the bullet.

Production carbine round | Standard 1900 round |

|

|  |

The conclusions here is that President Roosevelt acquired in late 1901 a preproduction prototype cased Luger hunting carbine with a limited amount of unidentified preproduction carbine ammunition. This ammunition was expended by early 1902, and the DWM carbine domestic packaged ammunition, only recently introduced in Germany, concurrently with the production Luger hunting carbine was not yet available in the United States. However, as of July 1902 the production carbine, nor the special ammunition was still not yet readily available in the United States. Since Tauscher did provide the army with 50 rounds of unidentified packaging carbine ammunition, it is quite probable that he was somehow involved with the Theodore Roosevelt cased preproduction prototype carbine original transaction. In a later July 23, 1902 dated letter from Crozier to the President states: returning to you your Luger automatic pistol-carbine, I have the honor to inform you that I have this day sent you by express a leather holster belonging to the arm.

However, as of July 1902 the production carbine, nor the special ammunition was still not yet readily available in the United States. Since Tauscher did provide the army with 50 rounds of unidentified packaging carbine ammunition, it is quite probable that he was somehow involved with the Theodore Roosevelt cased preproduction prototype carbine original transaction. In a later July 23, 1902 dated letter from Crozier to the President states: returning to you your Luger automatic pistol-carbine, I have the honor to inform you that I have this day sent you by express a leather holster belonging to the arm. This holster has never been identified.

This holster has never been identified.

Even though the President Theodore Roosevelt carbine has long since disappeared, last seen in a circa 1913 photograph with his son Kermit while in S. America, there is the possibility that the serial number may yet be identified as the original case survives in the Sagamore Hill Museum Collection.[6] One item in the case is the original wooden stock with push-button attaching iron, possibly with a two-digit serial number, of which, 58 comes to mind, the only surviving extant example, identical to the Roosevelt carbine as originally configured, conveniently being located in the United States with a provenance dating back to the 1950s, a time of little import activity of Lugers.

there is the possibility that the serial number may yet be identified as the original case survives in the Sagamore Hill Museum Collection.[6] One item in the case is the original wooden stock with push-button attaching iron, possibly with a two-digit serial number, of which, 58 comes to mind, the only surviving extant example, identical to the Roosevelt carbine as originally configured, conveniently being located in the United States with a provenance dating back to the 1950s, a time of little import activity of Lugers.

The above theory was put together before it was known from a subsequent conversation with Charles Kenyon, Jr. that he had visited the Sagamore Hill Museum and personally viewed the President Roosevelt Luger hunting carbine presentation case and wooden stock with push-button attaching iron and noted no serial number. Combined with the fact that the Teddy Roosevelt Luger carbine, if ever located will have a modified front and rear sight, done at the Springfield Armory in 1902.

It is amazing that President Theodore Roosevelt, how he learned of and managed to aquire a preproduction prototype Luger carbine, only one of a handful made with the slim tapered barrel, barely weeks or months after it was made. The fact that it was cased, suggest it was a (presentation) gift, is a testament to the business acumen of DWM. The association of Tauscher with the U.S. Army, and General Crozier, Chief of Ordnance and of Crozier to T. Roosevelt[7], identified by documented correspondence between Roosevelt’s Springfield Armory proxy Frank H. Phipps, and Brigadier General Crozier, is an insight as to how Roosevelt acquired his preproduction prototype Luger hunting carbine.

Kenyon in his June 2002 Gun Report article titled Sorting out the Luger Carbines-Part II further elaborates on the above comments: Your editor is inclined to believe that the unique and limited group of two-digit serial carbines were probably assembled in the D.W.M. R&D model or design prototype shop around late 1901 or very early 1902. This would be about concurrent with the 10000 commercial serial series Lugers. These carbines may have been a first run or, if you will, a prototype design for a proposed introduction of a (hunting) carbine configuration Luger. Your editor also is inclined to believe that these few examples (up to 100 with minor variations in configuration) were probably retained in archives or finished goods for some lengthy time and subsequently sold off during a general clearing out of old stock, perhaps as late as 1920.

A classic example of Kenyon’s theory regarding the 1920 time frame excessing of these carbines with 1-3-5, five-position graduated rear sights and push-button stock lugs is a Chilean “type” carbine Luger with a graduated 2-4-6 rear sight and combination push-button/turn lever stock lug is GL Chilean “type” presentation Luger, serial number 10005 with a receiver and barrel stamped with 1920s type vertical crown N nitro proofs. Again, using Kenyon's supposition of these early carbines as “in-house” prototypes, especially the very first with the slim tapered barrels makes sense. The President T. Roosevelt cased carbine is the only exception being presented to President Roosevelt in late 1901, early 1902, coincidently in the same time frame as the US Army receipt of 1000 Test Eagle Lugers, was meant to influence the outcome.

Again, using Kenyon's supposition of these early carbines as “in-house” prototypes, especially the very first with the slim tapered barrels makes sense. The President T. Roosevelt cased carbine is the only exception being presented to President Roosevelt in late 1901, early 1902, coincidently in the same time frame as the US Army receipt of 1000 Test Eagle Lugers, was meant to influence the outcome.

The fact that the President Roosevelt carbine didn’t shoot well, requiring extensive modifications to the front and rear sights is testimony to the fact that these very first carbines were made exclusively for DWM “in-house” testing only, not yet ready for sale to the general public, it is therefore, despite the intention of the DWM “gift” TR cased presentation carbine, it is doubtful it had a positive effect of the U.S. Army Luger trials. There were other preproduction cased transitional presentation carbines, serial 77 as an example, however, except for the graduated 1-3-5,

five-position rear link sight and new preproduction frame forging push-button stock lug, the balance of the gun is of production configuration.

it is doubtful it had a positive effect of the U.S. Army Luger trials. There were other preproduction cased transitional presentation carbines, serial 77 as an example, however, except for the graduated 1-3-5,

five-position rear link sight and new preproduction frame forging push-button stock lug, the balance of the gun is of production configuration.

Since Carbine 58 lacks a Germany export stamp, whereas the only other graduated rear link sight Chilean “type” prototype carbine GL presentation Luger 10005 , mentioned above, exported to this country, did not escape the otherwise mandatory Germany export stamp, indicates Carbine 58 may have entered the country much earlier, along with the President Roosevelt cased presentation carbine, under the same conditions of the U.S. Army Test Eagle Lugers, which also lack Germany export stamps.

, mentioned above, exported to this country, did not escape the otherwise mandatory Germany export stamp, indicates Carbine 58 may have entered the country much earlier, along with the President Roosevelt cased presentation carbine, under the same conditions of the U.S. Army Test Eagle Lugers, which also lack Germany export stamps.

The Preproduction Prototype Carbine 1-3-5, five-position graduated tangent leaf rear link sight

TBLAP page 250 The development and rapid obsolescence of the delicate multi-range sight mounted on the rear toggle after a handful of carbines and pistols indicates that this feature was soon found wanting in testing or in service, possibly due to jarring on recoil, possibly due to general fragility, since many sections in the moving leaf are less than 1 mm thick and the component is tempered spring-hard, making it prone to cracking. There is also the practical consideration that, when extended to maximum range (600 m), the leaf of the sight comes unnervingly close to the web of the hand when the toggle recoils to its fully open position, especially when the stock is fitted to either carbine or pistol. It is hardly likely that having tried this design on the carbine and found it unsatisfactory, it would then be used on the pistol, or vice versa, without any substantive redesign or reinforcement. Since this is the case, the only difference being the number of range stops and the graduations, it must be concluded that these two versions of the sight were produced near simultaneously, with their weapons.

In TBLAP, page 250 cited above, Sturgess accurately describes the reasons for the rapid abandonment of the graduated rear sights of both the Luger hunting carbine and the small batch of Chilean military carbine pistols with the statement that: …it must be concluded that these two versions of the sight were produced near simultaneously, with their weapons.

Even though both versions function or operate identically does not mean they are mechanically identical. The key here is the statement …these two versions of the sight were produced near simultaneously, with their weapons. A close examination of the Carbine 58 graduated 1-3-5, five-position tangent leaf rear sight, specifically the underside of the adjustable underside bifurcated elevator leaf tangent slide reveals that it is of a different, more complex construction than the Chilean 2-4-6, six-position rear tangent leaf sight in the same area.

Per subsequent correspondence with Charles Kenyon, Jr., world famous and noted Luger author and collector, who is intimately familiar with Carbine 58 and specifically the graduated 1-3-5, five-position and 2-4-6, six-position Chilean military carbine rear link sights, with Carbine 58 being featured in

© 1969 Lugers At Random and again

in © 1991 Luger: The Multi-National Pistol,

and again

in © 1991 Luger: The Multi-National Pistol, the following conclusions were reached with the aid of sketches made by and generously provided by Kenyon.

the following conclusions were reached with the aid of sketches made by and generously provided by Kenyon.

The differences of configuration of the Chilean 2-4-6 military carbine rear link adjustable sights and all 1-3-5 hunting carbine rear link adjustable sights, including Carbine 58 involve only the retention method of the sliding adjustable elevator or sliding tangent leaf, with the most mechanically complicated being the 1-3-5 hunting carbine. The Carbine 58 sliding, bifurcated

underside tangent elevator leaf has a groove or slot milled in the left integral underside, or lengthwise to the bottom of the leaf. This slot engages a curious horseshoe type link, of which the bottom horizontal shaft acts to retain the rear link underside anchored coupling “S” link and keeps the leaf retained when assembled, while the upper horizontal shaft is notched in the middle where the upper edge tip extension engages the underside milled recess tangent sight retaining slot, which stops the sliding tangent sight at maximum extension. Click here to see Sketch 1.

This slot engages a curious horseshoe type link, of which the bottom horizontal shaft acts to retain the rear link underside anchored coupling “S” link and keeps the leaf retained when assembled, while the upper horizontal shaft is notched in the middle where the upper edge tip extension engages the underside milled recess tangent sight retaining slot, which stops the sliding tangent sight at maximum extension. Click here to see Sketch 1.

The 2-4-6, six-position tangent sight leaf uses a “simpler” method utilizing a “J” type link with lower, longer section shaft used to anchor the “S” shaped coupling link to the rear link underside. The end of the upper, shorter length of the ”J” type link engages a milled out channel in the left underside edge of the sliding tangent leaf sight. The right side underside of the bifurcated sliding tangent leaf is the moving scissor arm portion, of which the spring loaded pivot point is anchored at the rear of the tangent leaf with a vertical pin.

The adjustment activation is accomplished by pressing in on the left and right side serrated rear grasping surfaces, immediately forward of the vertical pivot anchor pin, of the sliding tangent elevator leaf with the thumb and opposing finger, disengaging the forward end of the arm in a counter clockwise direction, away from the graduated elevation slots located in the right side upper edge of the right side channel guide of the lower integral part of the sight, thereby allowing resetting of elevation. The method of adjustment described is identical in operation to both the 1-3-5 and 2-4-6 graduated sliding tangent leaf sights. Click here to see Sketch 2

In the page 2 sketch, Kenyon states: Note: This concept utilizes a much more simple manufacture sight leaf (a minimum of two less, separate machining steps) and “J” spring link pin (notch eliminated). Since it is a universal process, I believe this design evolved – rapidly – from the earlier, more complex configuration. The use of the term simple in relation to German engineering is a relative term, as simpler means only slightly less complex.

Sturgess did disassemble the 2-4-6, six-position graduated tangent leaf rear sight of GL presentation Luger 10005 pictured in © 2010 Pistole Parabellum, Volume I, page 196, figure 204 and © 2010 & 2011 TBLAP,

Volume I, page 196, figure 204 and © 2010 & 2011 TBLAP, Volume I, page 249, Fig. 3-152, currently of the Land of Borchardt collection and was obviously aware of its internal construction, but since he did not have a preproduction prototype Luger hunting carbine with a 1-3-5, five-position graduated rear tangent leaf sight in his collection, he was not aware of the internal mechanical differences. If he was, surely he would have discussed the differences and their implications, yet without specifics, states that the hunting carbine sports the first pattern tangent (meaning externally viewed 1-3-5 hunting carbine vs. 2-4-6 Chilean carbine graduated sight increments) rear sight in the Fig. 3-145 text caption.

Volume I, page 249, Fig. 3-152, currently of the Land of Borchardt collection and was obviously aware of its internal construction, but since he did not have a preproduction prototype Luger hunting carbine with a 1-3-5, five-position graduated rear tangent leaf sight in his collection, he was not aware of the internal mechanical differences. If he was, surely he would have discussed the differences and their implications, yet without specifics, states that the hunting carbine sports the first pattern tangent (meaning externally viewed 1-3-5 hunting carbine vs. 2-4-6 Chilean carbine graduated sight increments) rear sight in the Fig. 3-145 text caption. Details below.

Details below.

TBLAP, Volume I, Chapter 3, page 241, Fig. 3-145 pictures several full color, high resolution detailed views of 9103C preproduction Luger carbine of the MoD Pattern Room collection. It is not certain if Sturgess personally took the pictures of, or examined the rear link graduated 1-3-5 tangent leaf underside at full extension. The Fig. 3-145 caption states: Details of transitional presentation carbine sn. 9103C, having the first pattern tangent rear sight, graduated 1-3-5, as the prototype carbines,…However, nowhere in the associated text describing 9103C does Sturgess elaborate as to how he came to the conclusion that the hunting carbine as having the first pattern tangent rear sight which seems to imply that the hunting carbine came before the 10000 series seven-inch (175mm) barrel Chilean 2-4-6 graduated tangent rear leaf sight carbines.

It is not certain if Sturgess personally took the pictures of, or examined the rear link graduated 1-3-5 tangent leaf underside at full extension. The Fig. 3-145 caption states: Details of transitional presentation carbine sn. 9103C, having the first pattern tangent rear sight, graduated 1-3-5, as the prototype carbines,…However, nowhere in the associated text describing 9103C does Sturgess elaborate as to how he came to the conclusion that the hunting carbine as having the first pattern tangent rear sight which seems to imply that the hunting carbine came before the 10000 series seven-inch (175mm) barrel Chilean 2-4-6 graduated tangent rear leaf sight carbines.

Alternately, Kenyon did disassemble the 1-3-5, five-position graduated tangent leaf rear sight of either Carbine 35, identified as part of his collection in 2002, or preproduction prototype Luger hunting Carbine 58 pictured in ©1991 LTMNP, page 54.

or preproduction prototype Luger hunting Carbine 58 pictured in ©1991 LTMNP, page 54. The sketches generously provided by Kenyon demonstrates since, at least 1991, that he was keenly aware of the detailed internal mechanical differences of both rear link graduated tangent leaf sight variations, having disassembled both variations, probably the 10010 GL presentation “Chilean” variation seven inch barrel 2-4-6, six-position rear link graduated tangent leaf sight, also pictured on the same page 54 of ©1991 LTMNP.

The sketches generously provided by Kenyon demonstrates since, at least 1991, that he was keenly aware of the detailed internal mechanical differences of both rear link graduated tangent leaf sight variations, having disassembled both variations, probably the 10010 GL presentation “Chilean” variation seven inch barrel 2-4-6, six-position rear link graduated tangent leaf sight, also pictured on the same page 54 of ©1991 LTMNP.

Kenyon has examined at least one other (Carbine 35) 1-3-5, five-position graduated tangent leaf sights of two-digit serial number preproduction prototype Luger hunting carbines and at least two 10000 series serial number “Chilean” 2-4-6, six-position rear link graduated tangent leaf sights it can be stated, therefore, that the internal rear link graduated tangent sight differences of Carbine (35) 58 and 10005 GL presentation Chilean “type” Luger are not coincidental or aberrations, but are representative or typical of two distinctive rear sight variations, identified or based specifically by the evolutionary internal aspects, not the external differences, which show differences, but not of an evolutionary or progressive nature. With the internal mechanics explained, using the Kenyon sketches and associated text descriptions, the collector simply has to adjust the rear tangent leaf to its maximum extension and observe the underside to identify the variation.

it can be stated, therefore, that the internal rear link graduated tangent sight differences of Carbine (35) 58 and 10005 GL presentation Chilean “type” Luger are not coincidental or aberrations, but are representative or typical of two distinctive rear sight variations, identified or based specifically by the evolutionary internal aspects, not the external differences, which show differences, but not of an evolutionary or progressive nature. With the internal mechanics explained, using the Kenyon sketches and associated text descriptions, the collector simply has to adjust the rear tangent leaf to its maximum extension and observe the underside to identify the variation.

In light of the above information regarding the evolution of the 1-3-5 and 2-4-6 prototype graduated sliding tangent leaf rear sights, it is difficult to reconcile the Sturgess assertions that the Chilean guns were made first, closely followed by the Luger hunting carbines, while simultaneously claiming the hunting carbine has the first pattern tangent rear sight.

TBLAP defined preproduction prototype carbines with push-button stock lug categories:

Group a): The prototype Chilean trial model pistols with graduated 2-4-6, six-position rear link sights.

Group b): The prototype hunting carbines with graduated 1-3-5, five-position rear link sights.

Group c): 175 mm barrel pistols with fixed rear sights.

TBLAP, Chapter 3, page 249 – Development of the Parabellum Pistol Possibly DWM also made a decision to speculatively develop the carbines of group b), rather than just to produce the handful of prototype Chilean pistol-carbines: the known survival rate of pistols from group c) is around 12 ex 50, i.e. some 24%. The four or so survivors of group b)

is around 12 ex 50, i.e. some 24%. The four or so survivors of group b) , with a similar or probably higher survival rate, imply no more than 10 - 12 of these prototype carbines were made despite their spread of serial numbers. This alone would not have justified special frame forgings with an attachment lug, since welded or brazed modifications, like the carbine fore-end support, would have sufficed for a few prototype examples, as it did for the main spring seating modifications of Old Model frames to make the first New Model prototypes.

, with a similar or probably higher survival rate, imply no more than 10 - 12 of these prototype carbines were made despite their spread of serial numbers. This alone would not have justified special frame forgings with an attachment lug, since welded or brazed modifications, like the carbine fore-end support, would have sufficed for a few prototype examples, as it did for the main spring seating modifications of Old Model frames to make the first New Model prototypes.

Note the TBLAP Group b) category curiously, contains mostly the surviving transitional carbines, citing four examples being 77, 9102C, 9103C and the Fig. 3-142 “unidentified serial number S. American” carbine and does not address or acknowledge three of the five identified in this article, except for the Fig. 3-142 unidentified S. American carbine, which are the first true preproduction prototype, two-digit serial number carbines with the 11¾-inch slim tapered barrels, including carbines 35 and 58, of which Carbine 58 is the only known surviving extant example of five identified carbines in this category. The early preproduction prototype carbines with the slim tapered barrel identified in TBLAP are the

category curiously, contains mostly the surviving transitional carbines, citing four examples being 77, 9102C, 9103C and the Fig. 3-142 “unidentified serial number S. American” carbine and does not address or acknowledge three of the five identified in this article, except for the Fig. 3-142 unidentified S. American carbine, which are the first true preproduction prototype, two-digit serial number carbines with the 11¾-inch slim tapered barrels, including carbines 35 and 58, of which Carbine 58 is the only known surviving extant example of five identified carbines in this category. The early preproduction prototype carbines with the slim tapered barrel identified in TBLAP are the

- Fig. 3-142 pictured, albeit unidentified “S. American” carbine,

- the Georg Luger group photo carbine

,

,

-

the President Theodore Roosevelt cased presentation carbine

. Not included in the Group b) “four or so survivors category” is the,

. Not included in the Group b) “four or so survivors category” is the,

-

Charles Kenyon, Jr. Collection Carbine 35

and,

and,

-

the Land of Borchardt Collection Carbine 58

leaving only the transitional/presentation push-button carbines 77, 9102C, 9103C and 9110C.

leaving only the transitional/presentation push-button carbines 77, 9102C, 9103C and 9110C.

9110C identified as a production configuration presentation carbine, except with a new push-button frame forging combination push-button/turn lever stock lug and matching, numbered stock. Note the rear gripstrap stock lug wooden grips terminate flush to the gripstrap edges (arrowed), typical to other noted push-button hunting carbines and Chilean push-button carbines, indicative to the commonality of the early push-button frame forgings.

typical to other noted push-button hunting carbines and Chilean push-button carbines, indicative to the commonality of the early push-button frame forgings.

1901 transitional hybrid prototype push-button/turn lever Carbine 60

1901 transitional hybrid hunting Carbine 60 with combination push-button/turn lever stock lug has been recently located, together with a circa 1901 no attaching iron serial number push-button hunting carbine stock.

together with a circa 1901 no attaching iron serial number push-button hunting carbine stock. Pictured are close-up views of the no serial number Carbine 60 stock push-button attaching iron.

Pictured are close-up views of the no serial number Carbine 60 stock push-button attaching iron. Hunting Carbine 60 has an unusual 1-3-5 rear link graduated, tangent leaf sight as it has an extra, unnumbered position and corresponding right side indent, at maximum extension, making it a six-position graduated, tangent leaf rear sight or "1-3-5-". Additionally, the numeric font sight numbers 1-3-5- are a larger 3.5mm in height vs. Carbine 58 numeric 1-3-5 smaller numeric font height of 2.5mm.

Hunting Carbine 60 has an unusual 1-3-5 rear link graduated, tangent leaf sight as it has an extra, unnumbered position and corresponding right side indent, at maximum extension, making it a six-position graduated, tangent leaf rear sight or "1-3-5-". Additionally, the numeric font sight numbers 1-3-5- are a larger 3.5mm in height vs. Carbine 58 numeric 1-3-5 smaller numeric font height of 2.5mm.

The most unusual difference observed of the Carbine 60 1-3-5-, six-position rear link sight is internal, based

on the underside configuration at maximum extension which is identical to the less complex Chilean 2-4-6 rear sight defined earlier. The visual effect of the added sixth-position as compared with preproduction prototype hunting Carbine 58 as viewed from above and in profile is striking, as with Carbine 58 and 60 tangent leafs at maximum extension, the Carbine 60 tangent leaf is noticeably higher and longer than Carbine 58.

which is identical to the less complex Chilean 2-4-6 rear sight defined earlier. The visual effect of the added sixth-position as compared with preproduction prototype hunting Carbine 58 as viewed from above and in profile is striking, as with Carbine 58 and 60 tangent leafs at maximum extension, the Carbine 60 tangent leaf is noticeably higher and longer than Carbine 58. Additionally, from a machining point of view or observation the six indents, although equally spaced, vary in length with indents 2 and 3 being longer than the indents of 1, 4, 5 and 6, giving the appearance of misalignment, inconsistent with expected DWM tool room machining precision, as compared with the straight-line alignment of the five-indents of Carbine 58 and others, another example being carbine 77.

Additionally, from a machining point of view or observation the six indents, although equally spaced, vary in length with indents 2 and 3 being longer than the indents of 1, 4, 5 and 6, giving the appearance of misalignment, inconsistent with expected DWM tool room machining precision, as compared with the straight-line alignment of the five-indents of Carbine 58 and others, another example being carbine 77. Interestingly, with the addition of a 600m or sixth-position to the rear sight is

that no other changes or adjustments were made to the production barrel configuration front fixed sight

Interestingly, with the addition of a 600m or sixth-position to the rear sight is

that no other changes or adjustments were made to the production barrel configuration front fixed sight or the tangent leaf V notch rear sight.

or the tangent leaf V notch rear sight.

Per earlier discussions in this article regarding the hunting carbine 1-3-5, five-position and the Chilean trials carbine 2-4-6, six-position rear link tangent leaf adjustable sights as described and explained by C. Kenyon, Jr., it was stated that the graduated tangent leaf rear link sights represented an evolution of assembly, i.e. complex (hunting carbine) to less complex (Chilean carbine). The graduated rear link adjustable tangent slide configuration of hunting Carbine 60, being apparently identical to the internal configuration of the less complex Chilean military carbine conflicts with the C. Kenyon explanation of the evolution of the graduated adjustable rear tangent leaf sights, both internally and being a hunting carbine with a six-position 1-3-5- rear sight vs. the recognized five-position 1-3-5 of which several hunting carbine and Chilean military carbine examples pictured herein.

conflicts with the C. Kenyon explanation of the evolution of the graduated adjustable rear tangent leaf sights, both internally and being a hunting carbine with a six-position 1-3-5- rear sight vs. the recognized five-position 1-3-5 of which several hunting carbine and Chilean military carbine examples pictured herein.

A brief detail of Carbine 60

Carbine 60 Forestock

The carbine 60 forestock interior cavity, at first glance, appears correct, except a closer inspection reveals that the forestock was originally made for the final production carbine thick wall barrel, where the area needed to be widened to accommodate the larger diameter rear barrel, tapered sleeve mounted, 4-position 100-300M adjustable sight.

at first glance, appears correct, except a closer inspection reveals that the forestock was originally made for the final production carbine thick wall barrel, where the area needed to be widened to accommodate the larger diameter rear barrel, tapered sleeve mounted, 4-position 100-300M adjustable sight.

Note the two different grain patterns at the interface between the existing forestock and the added pieces. These observations can be seen in close-up, multiple marked-up views of the carbine 60 forestock cavity as compared to an original, unmodified forestock underside cavity of carbine 77 with an identical barrel to carbine 60.

The rear and middle toggle links are not serialized, nor is the rear frame, except for the forestock tang. The receiver stop lug, barrel, trigger, breechblock and frame extension, (pictured) grips and second issue wide grip safety (not pictured) are serial number stamped. As stated, except for the trigger and the frame forestock tang extension, the frame proper is unnumbered, which would be expected being a circa 1902 or later production carbine frame. The barrel, frame, frame tang extension, the wooden forestock and wedge are production. Only the combination push-button/turn lever stock lug and rear sight appear to be of 1901 preproduction prototype carbine configuration. The production style forestock sliding wedge is unusually hand scribed on the underside with the (60) serial number. This is the first noted instance of a serial number marked production carbine forestock wedge, with the exception of transitional/hybrid Carbine 77 forestock wedge, which is stamped, not scribed

As stated, except for the trigger and the frame forestock tang extension, the frame proper is unnumbered, which would be expected being a circa 1902 or later production carbine frame. The barrel, frame, frame tang extension, the wooden forestock and wedge are production. Only the combination push-button/turn lever stock lug and rear sight appear to be of 1901 preproduction prototype carbine configuration. The production style forestock sliding wedge is unusually hand scribed on the underside with the (60) serial number. This is the first noted instance of a serial number marked production carbine forestock wedge, with the exception of transitional/hybrid Carbine 77 forestock wedge, which is stamped, not scribed .

.

Regarding the push-button stock lug of Carbine 60, dimensions of the front-to-rear Carbine 60 rear gripstrap in profile were taken (˜48.2mm) and compared against a circa 1902 production carbine frame gripstrap (˜48.2mm) and a 1901 Chilean carbine frame push-button gripstrap. The 48.2mm front-to-rear gripstrap dimensions indicate that the frame of Carbine 60, despite the second issue thumb safety, is identical to the circa 1902 or later production carbine frame and that the integral stock lug was originally machined to accept a production turn lever attaching iron, and that the right side stock lug channel appears to be post manufacture modified by adding a detent to accept a preproduction push-button attaching iron spring loaded catch, whereas the Chilean military trials carbine frame gripstrap dimension is correct, being of smaller, ˜44.4mm front to rear length, and should be otherwise dimensionally identical to Carbine 60. Additionally, when the circa 1902 production carbine frame forging stock lug was introduced, the lower rear gripstrap was “beefed-up”, extending length of the stock lug beyond the standard production wooden grips lower edge rear profile, which is apparent when viewing the Carbine 60 with circa 1902/3 production carbines, P.04 and P.08 turn lever stock lugs/wooden grip border interfaces.

The 48.2mm front-to-rear gripstrap dimensions indicate that the frame of Carbine 60, despite the second issue thumb safety, is identical to the circa 1902 or later production carbine frame and that the integral stock lug was originally machined to accept a production turn lever attaching iron, and that the right side stock lug channel appears to be post manufacture modified by adding a detent to accept a preproduction push-button attaching iron spring loaded catch, whereas the Chilean military trials carbine frame gripstrap dimension is correct, being of smaller, ˜44.4mm front to rear length, and should be otherwise dimensionally identical to Carbine 60. Additionally, when the circa 1902 production carbine frame forging stock lug was introduced, the lower rear gripstrap was “beefed-up”, extending length of the stock lug beyond the standard production wooden grips lower edge rear profile, which is apparent when viewing the Carbine 60 with circa 1902/3 production carbines, P.04 and P.08 turn lever stock lugs/wooden grip border interfaces. Click here

Click here to see Carbine 60 push-button stock lug/production carbine stock lug overlay animation.

to see Carbine 60 push-button stock lug/production carbine stock lug overlay animation.

Details of connecting the push-button wooden stock to the Luger hunting carbine and Chilean military carbine

The hunting carbine and Chilean military trials carbine frame forging push-button stock lug right side channel, at the upper end of the channel, is located a short rectangular shaped, sloped slot to accept the corresponding angled attaching iron push-button catch that, while depressing or pushing the spring loaded attaching iron button, allowing the attaching iron channel to slide up the mating stock lug left and right side channels, stops when the attaching, spring loaded angled catch engages the right side channel upper detent, thereby locking the stock lug and attaching iron in place.

In actuality, it is not necessary to depress the attaching iron push-button to connect to the stop lug, as the intent of the angle or slope of the attaching iron spring loaded catch was forced to depress flush to the right-side channel wall at entrance, continuing to slide up the right-side stock lug channel until the spring loaded attaching iron catch engages the detent. This is evident when examining the wear to the right-side stock lug channel. However, due to the strong spring pressure of the attaching iron push-button catch, it is recommended to completely depress the attaching iron button while connecting to the stock lug, until the catch is fully seated in the right side upper channel detent.

Carbine 60 Push-Button/Turn Lever stock lug machining details

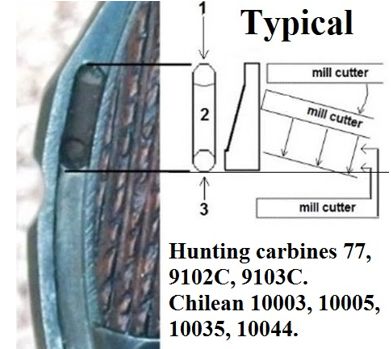

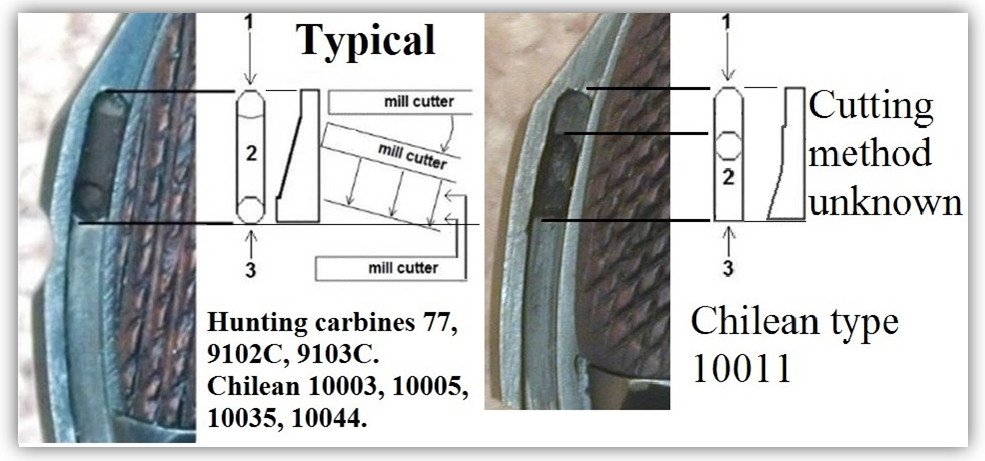

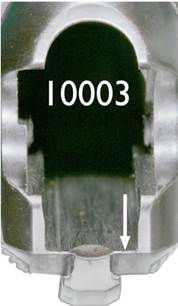

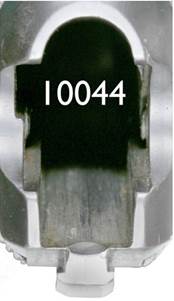

The right side stock lug curved channel rectangular shaped, angled cut detent was machined into the rear frame stock lug upper channel of all preproduction prototype and prototype/transitional Luger hunting carbine frame and Chilean carbine frame forging push-button stock lugs by a mill cutter, resulting in a small, mostly flat surface at each end of the short 9mm detent with an angled, smooth finish in between the two flats at each end of the detent. Shown are 10005, 10035, 10044 Chilean carbine and 9102C, 9103C Luger hunting carbine push-button stock lug right side channel detents that exhibit these features. As previously noted, these first Luger hunting carbines and the one time only Chilean push-button stock lug frame forgings have shorter front-to-rear gripstrap dimensions from the slightly longer, final circa 1902/3 production frame Luger hunting carbine forgings with the final turn lever type stock lugs.

As previously noted, these first Luger hunting carbines and the one time only Chilean push-button stock lug frame forgings have shorter front-to-rear gripstrap dimensions from the slightly longer, final circa 1902/3 production frame Luger hunting carbine forgings with the final turn lever type stock lugs.

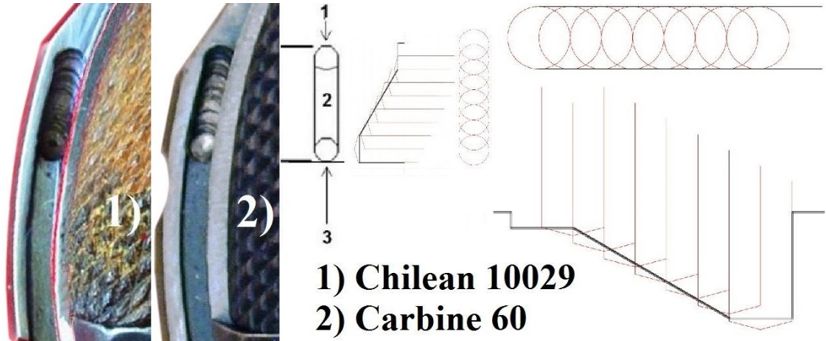

Detent machining method/details of typical push-button stock lugs of hunting carbines and Chilean military carbines vs. hunting Carbine 60 and Chilean military carbine 10029

a) The milling of the slot and push-button detent for typical push-button stock lugs of hunting carbines and Chilean military carbines was performed by the factory as follows. A jig was used to hold the frame in place so that the 2mm flat bottomed mill could be positioned over location 1, the upper end of the groove. The mill was plunged 0.5mm into the stock lug and traversed along the full length of the lug, cutting the groove as the mill progressed along the curvature of the stock lug. The factory then used a jig which rotated the frame to allow the 2mm end mill to follow the curvature of the stock attachment groove and was set with its rotational axis inclined at an angle to the axis of the milling cutter. This cut was made from position 1 to position 3 as shown in the figure. The frame was again set in the first jig with the frame flat and a single finishing cut at position 3 was used to bring the recess to the correct depth and square up the end thus accounting for the smooth, circular mark at the bottom of the detent.

A jig was used to hold the frame in place so that the 2mm flat bottomed mill could be positioned over location 1, the upper end of the groove. The mill was plunged 0.5mm into the stock lug and traversed along the full length of the lug, cutting the groove as the mill progressed along the curvature of the stock lug. The factory then used a jig which rotated the frame to allow the 2mm end mill to follow the curvature of the stock attachment groove and was set with its rotational axis inclined at an angle to the axis of the milling cutter. This cut was made from position 1 to position 3 as shown in the figure. The frame was again set in the first jig with the frame flat and a single finishing cut at position 3 was used to bring the recess to the correct depth and square up the end thus accounting for the smooth, circular mark at the bottom of the detent.

b)The milling of the detent in hunting Carbine 60 and Chilean military carbine 10029 was made without access to such a jig used by the factory. It would have been possible to use a rotary table propped up at one side to simulate the factory jig, but this was not done. The angled cut in the detent was simulated very poorly by making a series of progressively deeper vertical cuts into the original stock lug groove or channel, hence the rough bottom of the recess as shown in the figure. The frame was fixtured against a rail to allow horizontal movement of the frame during the drilling process. Since the spacing of the cuts are not equal at the bottom of the angle cut indicates that the horizontal movement was done without the aid of any encoder feedback, but purely by manual translation in roughly half mm increments.

It would have been possible to use a rotary table propped up at one side to simulate the factory jig, but this was not done. The angled cut in the detent was simulated very poorly by making a series of progressively deeper vertical cuts into the original stock lug groove or channel, hence the rough bottom of the recess as shown in the figure. The frame was fixtured against a rail to allow horizontal movement of the frame during the drilling process. Since the spacing of the cuts are not equal at the bottom of the angle cut indicates that the horizontal movement was done without the aid of any encoder feedback, but purely by manual translation in roughly half mm increments.

Presentation transitional prototype hunting carbine 77 frame forging with push-button stock lug has been personally examined and the right side stock lug channel upper push-button detent was also done with a mill cutter in the manner described in paragraph a) above,

being identical, except for the magazine well knife-edge rear wall

in the manner described in paragraph a) above,

being identical, except for the magazine well knife-edge rear wall , to the Chilean examples 10005, 10035 and 10044 and Luger hunting carbines 9102C, 9103C and

9110C.

, to the Chilean examples 10005, 10035 and 10044 and Luger hunting carbines 9102C, 9103C and

9110C. Additionally, Carbine 60 is pictured with Carbine 77 with close-up inserts of the lower left side grip and integral stock lugs showing Carbine 77 to be of the first frame forging with push-button stock lug while Carbine 60 appears to be the circa 1902/3 production frame forging with turn lever stock lug.

Additionally, Carbine 60 is pictured with Carbine 77 with close-up inserts of the lower left side grip and integral stock lugs showing Carbine 77 to be of the first frame forging with push-button stock lug while Carbine 60 appears to be the circa 1902/3 production frame forging with turn lever stock lug.

Pictured are a Luger hunting carbine push-button stock lug/attaching iron mating vs. a final circa 1903/4 production navy carbine turn lever stock lug/board-stock attaching iron mating.

Pictured are a Luger hunting carbine push-button stock lug/attaching iron mating vs. a final circa 1903/4 production navy carbine turn lever stock lug/board-stock attaching iron mating.

Furthermore, based on the production length front-to-rear gripstrap, the Carbine 60 frame appears to be a circa 1902 or later production forging with the final turn lever stock lug. This is not the first example of a production frame forging turn lever stock lug modified to a push-button stock lug as a fake “Chilean push-button” carbine, serial number 10029 so modified has been (unsuccessfully) offered by a major Luger dealer for several years as an original Chilean military trials push-button stock lug, fixed rear sight carbine. Despite Carbine 60 having the correct second issue thumb safety lever does not necessarily automatically imbue authenticity as fake Chilean trials carbine 10029 also sports a second issue thumb safety installed in a circa 1917 P.08 modified frame.

This is not the first example of a production frame forging turn lever stock lug modified to a push-button stock lug as a fake “Chilean push-button” carbine, serial number 10029 so modified has been (unsuccessfully) offered by a major Luger dealer for several years as an original Chilean military trials push-button stock lug, fixed rear sight carbine. Despite Carbine 60 having the correct second issue thumb safety lever does not necessarily automatically imbue authenticity as fake Chilean trials carbine 10029 also sports a second issue thumb safety installed in a circa 1917 P.08 modified frame.

In the case of 10029, the stock lug detent was added as described above in paragraph b) to a circa 1917 manufactured P.08 frame forging with turn lever stock lug, of which the stock lug of the 1902 carbine, the 1904 navy and the P.08 are essentially identical. The final observation strongly suggests that the Carbine 60 frame is a circa 1902 or later carbine frame forging with an, as manufactured, turn lever stock lug. When the circa 1902 production forging carbine stock lug was introduced, the lower rear gripstrap was “beefed-up”, extending the stock lug beyond the 1900 production rear wooden gripstrap lower edge profile, which is apparent when viewing the Carbine 60 and production turn lever stock lug/wooden grip border interface. This feature is missing in the several identified first 1901 frame forgings with push-button integral stock lugs of both the circa 1901 Chilean and Luger hunting carbines with the M1900 production wooden grip lower rear profile.

This feature is missing in the several identified first 1901 frame forgings with push-button integral stock lugs of both the circa 1901 Chilean and Luger hunting carbines with the M1900 production wooden grip lower rear profile.

Pictured are the left and right side stock lug guide channels of hunting Carbine 60, Chilean military carbine 10029 and a typical production P.08 turn lever stock lug. Pay particular attention to the basically identical left and right side rear termination profile of the wooden grips of all three examples, which are typical production. Also, note the machining commonality of the right side, post manufacture added stock lug

channel push-button detents of Carbine 60 and Chilean military trials carbine 10029. It is interesting to note that the push-button detent was added to Carbine 60, originally manufactured with an existing turn lever stock lug, while in the case of 10029 the right side channel push-button detent was added to a P08 frame, right side stock lug channel, which ironically, required the “filling” of the turn lever indent. Several genuine, authenticated circa 1901 transitional push-button stock lugs were later modified to accept a production turn lever attaching iron by adding the “scoop-out” to the rear of the frame stock lug.

Several genuine, authenticated circa 1901 transitional push-button stock lugs were later modified to accept a production turn lever attaching iron by adding the “scoop-out” to the rear of the frame stock lug.

As to whether Carbine 60 is authentic is up to the reader, although in a hypothetical, predictable defense of hunting carbine 60, supporters or proponents of the authenticity of Carbine 60 will state that: due to the transitional nature of these preproduction prototype Luger carbines, differences are to be expected since there are too few examples to examine in detail, one cannot categorically state that any specific differences imply aftermarket manufacture modifications. However, with the chronological out-of-sequence differences observed of the Carbine 60 graduated adjustable tangent rear leaf sight in relation to other known 1-3-5, five-position rear link sights and in combination with the difficulty of rationalizing the established, well-defined configuration of the standard production turn lever/push-button stock lug in relation to Carbine 60, of which original push-button stock lugs of the preproduction prototype hunting and Chilean military carbines have been later DWM factory or tool room modified to accept turn lever attaching irons, they were not done in the manner described of Carbine 60.

and in combination with the difficulty of rationalizing the established, well-defined configuration of the standard production turn lever/push-button stock lug in relation to Carbine 60, of which original push-button stock lugs of the preproduction prototype hunting and Chilean military carbines have been later DWM factory or tool room modified to accept turn lever attaching irons, they were not done in the manner described of Carbine 60.

In fact, contrary to the above assertions, there are enough first frame forging stock lug/push-button examples of both Luger hunting carbines and Chilean military trials carbines to establish the conclusions reached.

Additionally, in the process of disassembly and reassembly of Carbine 60 for examination and pictures it was noted that the toggle link assembly at the rear link axle pin binds in the receiver and that the receiver severely binds or sticks in the frame at the rear frame cam walls, and with no visible evidence of damage, suggests that some of the parts may not be original to the assembly.

Another argument presented by proponents of the originality of Carbine 60, specifically regarding right side stock lug channel push-button detent machining is that it is original and that 10029 was copied from Carbine 60. This argument would be convincing if it were not for the fact that 10029 is a complete and total fraud, being a bizarrely transformed production P.08 frame.

Since the above detailed examination months earlier and resulting discussion above, Carbine 60 has since been re-examined, revealing that the right side attaching iron channel push-button recess detent has been modified by possibly removing or minimizing some of the circular machining marks, followed by a somewhat sloppy, partial cold blue application, further hiding or softening of the remaining, more pronounced circular machining marks. Note the very pronounced

circular machining marks from top to bottom of the original unmodified detent channel or slot vs. the less distinctive circular machining marks at the lower

section of the modified push-button detent that tend to blur as one moves further up the channel.

Note the very pronounced

circular machining marks from top to bottom of the original unmodified detent channel or slot vs. the less distinctive circular machining marks at the lower

section of the modified push-button detent that tend to blur as one moves further up the channel.

Additionally, Carbine 60 sports a push-button wooden stock with an unnumbered attaching iron and wooden stock with yet a third type final production sling swivel loop. See below. Also the binding problem encountered earlier has been resolved as the action now functions more smoothly.

Hunting Carbine 35 Push-Button Wooden Stock

Hunting Carbine 35 wooden stock, currently part of the Land of Borchardt Collection, with push-button attaching iron is basically identical in shape and hatching pattern to other preproduction prototype hunting carbine stocks pictured herein, except the zig-zag border termination is more exaggerated or larger with the straight line conforming zig-zag border being slightly wider than other examples and the finish is more brown than amber in appearance as other examples. Although the push-button serial number 35 is unusually stamped on the attaching iron underside tang, it is not the only such stamped example in this push-button hunting carbine stock series.

Although the push-button serial number 35 is unusually stamped on the attaching iron underside tang, it is not the only such stamped example in this push-button hunting carbine stock series. Another difference or exception is the style of the sling swivel loop, which is slightly different from other pictured early sling swivel loops.

Another difference or exception is the style of the sling swivel loop, which is slightly different from other pictured early sling swivel loops. In addition, the wooden stock underside hole for the second variation sling swivel loop was not partially countersunk, longitudinally for the flush mount installation of the sling swivel loop post flange as were all other observed examples, preproduction and production. Pictured are multiple views of Carbine 35 preproduction prototype push-button wooden stock.

In addition, the wooden stock underside hole for the second variation sling swivel loop was not partially countersunk, longitudinally for the flush mount installation of the sling swivel loop post flange as were all other observed examples, preproduction and production. Pictured are multiple views of Carbine 35 preproduction prototype push-button wooden stock.

The authenticity of Carbine 35 preproduction push-button stock is reinforced by the fact of the existence

of preproduction prototype Luger hunting carbine 35 featured in a 2002 Gun Report magazine article written by Charlie Kenyon, Jr., pictured and discussed in

the Gun Report article as part of his collection. Carbine 35 still retains its push-button stock lug, whereas Carbine 58, the subject of this article, has had its stock lug removed. Nevertheless, Luger Hunting Carbine 58 is pictured with Carbine 35 push-button stock. Note the similarity of the finish of the forestock of Carbine 58 and the Carbine 35 push-button stock.

Carbine 35 still retains its push-button stock lug, whereas Carbine 58, the subject of this article, has had its stock lug removed. Nevertheless, Luger Hunting Carbine 58 is pictured with Carbine 35 push-button stock. Note the similarity of the finish of the forestock of Carbine 58 and the Carbine 35 push-button stock.

As a matter of note there are three identified variations

of the left side push-button detent;

Unnumbered Push-Button Hunting Carbine Stock currently mated to Carbine 60

This stock is basically identical to LOB Hunting Carbine stock 35, except without a serial number stamped on the push-button attaching iron.

except without a serial number stamped on the push-button attaching iron. The finish is closer in color and hue to other observed hunting carbine stocks. As a matter of note of all observed, matching push-button rigs, the wooden forestock and hunting carbine wooden stock sling swivel loop external styles are identical.

The finish is closer in color and hue to other observed hunting carbine stocks. As a matter of note of all observed, matching push-button rigs, the wooden forestock and hunting carbine wooden stock sling swivel loop external styles are identical.

Pictured is the underside of Carbine 35 and Carbine 60 unnumbered Push-Button wooden stocks showing the different sling swivel loop styles with the Carbine 35 sling swivel loop with assembly machine screw set to loop pedestal attachment, similar to the Carbine pistol 58 forestock sling swivel loop, whereas the sling swivel loop of the unnumbered stock of Carbine pistol 60 is the final production style without a machine screw assembly.

with the Carbine 35 sling swivel loop with assembly machine screw set to loop pedestal attachment, similar to the Carbine pistol 58 forestock sling swivel loop, whereas the sling swivel loop of the unnumbered stock of Carbine pistol 60 is the final production style without a machine screw assembly.

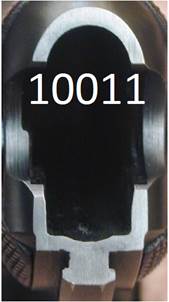

Chilean Type Carbine Push-Button Luger Serial Number 10011

The following is a discussion of another heretofore unpublished example of a Chilean “type” carbine, push-button Luger serial number 10011 with a 1-3-5 multi-position adjustable rear link mount sight. 10011 is doubly unique as the chamber sports a gold inlaid insignia H.T. over 1903. The initials are unknown, however, what comes to mind is Hans Tauscher, the period 1901 – 1916 DWM representative for the United States, Canada and South America.

The initials are unknown, however, what comes to mind is Hans Tauscher, the period 1901 – 1916 DWM representative for the United States, Canada and South America.

A brief detail of Chilean Type Carbine 10011