“1903 Experimental” Toggle Link assembly patent

“1903 Experimental” Toggle Link assembly patent

Home page

Article created: Wednesday, July 28, 2004

Home page

Article created: Wednesday, July 28, 2004

“1903 Experimental” Toggle Link assembly patent

“1903 Experimental” Toggle Link assembly patent

The June 2004 Gun Report “Lugers at Random” column by C. Kenyon, Jr. featured a story on a very interesting subject, specifically the “1903 Experimental” Toggle Link assembly covered by Georg Luger’s December 1903 patent submittal No. 851, 538 granted by the U.S. Patent Office in April 1907. The article pictured and discussed a prototype example that was designed after certain aspects of the subject patent as described by Kenyon. He asks the question: “Are there more examples?” It can be stated empirically that there are more examples. To my knowledge there are two extant examples. I have, many years ago, personally examined one example in a major collection and have detailed B&W photos of another example that is identical to the examined example. This article pictures and discusses one of these examples, a Model 1900 Luger with a “1903 Experimental” Toggle Link assembly.

It should be noted that the information presented represents a laypersons point of view. Some conjecture and theory have been introduced and may not be necessarily accurate, correct or germane but with the intent to stimulate more conversation and dialogue on a very interesting design concept.

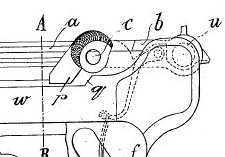

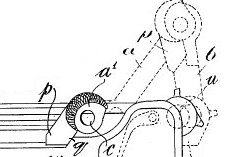

The example gun has a very low three digit commercial serial number. Several interesting conditions/situations stand out when comparing the Kenyon example against the Land of Borchardt (LOB) example: The Kenyon example professes to be a true first example prototype “in the white” with a non standard, incomplete machined receiver, radically modified toggle link assembly and with no serial number or at least not mentioned in the article. As a matter of note, most observed prototype or experimental Lugers such as the Swiss prototypes, pre-production Borchardt-Lugers or the 10000B series are serialized and exhibit the highest quality of fit and rust blue finish. The LOB “1903 Experimental” Luger exhibits, with the exception of the “1903 experimental” toggle link assembly and rear receiver forks abutment change, completely commercial production machining, standard commercial serial number placement and a standard rust blue finish. It is the toggle knobs of the LOB example that differs uniquely from the Kenyon example as the dish or scoops of the Kenyon example are production oriented in profile, i.e. the right and left side toggle knobs and the right side toggle lock is vertical as the 1900 production Lugers. The LOB toggle knobs example is oriented, with the toggle lock used as a reference, inexplicitly counter clockwise approximately 15°; a very curious design. The reason for this orientation is unclear as of this writing and decidedly a more difficult machining proposition than the Kenyon example. The top and underside rear and middle toggle links of both examples appear to be the same. Pictured here is a profile view of the LOB style example experimental toggle link assembly.

The December 1903 patent application for this unique toggle link assembly design was granted in 1907. However, the very low three digit serial number range of the LOB example and the second not shown example (serial number is within five digits of the pictured LOB example) suggests manufacture in 1901 or early 1902 at the very latest. The Kenyon example, which is described in his article as the first true example prototype, would have to have been fabricated even earlier. Also, as with most patent drawings, the end product does not always reflect the original patent drawing intent in its entirety. In this case, the toggle knobs of the 1903 patent drawing are not the same as the two examples pictured and the frame cam ramp design appears to be standard production configuration, without the added left side frame rail abutment of the patent drawing, p and q.

This is very significant, as the most important new design element of the patent drawing is “the toggle projection (p) striking the small shoulder on the right side frame panel rear (q)” is missing on both the Kenyon and LOB examples. It would be interesting to see the changes required on the right side frame rail of the gun that would be needed to engage the right side toggle projection. At a minimum, the gun would require the removal of the toggle lock frame retention claw and reinforcement in the frame rail area that was originally slotted to accept the lower section of the claw. The toggle knob rearward travel of the Kenyon and LOB examples is broken in the traditional manner by the rear of the toggle knobs sliding up the cam ramps on the rear of the frame.

The apparent intent of the designer in reversing the links was to have the web reinforced front link with the added integral toggle projection (p) doing the initial work of breaking the joint by impacting with the added frame panel abutment(s), the rear link going along for the ride whereas the conventional toggle link configuration had the rear link, i.e. axle pin do the work of breaking the joint. The reason for the receiver fork abutment change and the subsequent change to the rear link of both examples comprises a kind of retarding action against the beating like recoil action, while effectively utilizing the recoil energy for opening the toggle joint and the parts are also preserved from excessive vibration and strain.

Even if this design were a success it would still require Luger to redesign the safety system of which the grip safety has been totally displaced. It would be interesting to observe the kinetics of the reverse toggle link assembly, with its added mass in the conventional frame configuration of the Kenyon and LOB examples, especially with the rearward receiver fork abutment change. The added mass along with the notoriously weak return properties of the old model Riband main spring could affect a positive return to battery. None of the changes suggested elimination of the toggle lock requirement unless the designer’s intent of improving the smoothness of the action, by inference, eliminates the reason for the toggle lock requirement (anti-bounce).

The rake of the LOB toggle knobs along with the other toggle link assembly modifications appear to reflect the 1903 patent drawing more than the Kenyon example. Interestingly, the positioning or location of the fluting on the toggle knobs suggests possibly that the LOB example is the work of an enterprising technician/mechanic using the patent drawing and did not notice that the 1903 patent drawing appears to lack a toggle lock assembly. It has been done before.

It is interesting to note the presence of the pre-World War I Lazy N commercial proof stamped on the LOB example receiver left side and the experimental modified middle link, giving some legitimacy to the variation and indicating that it was “excessed” several years later after its manufacture, probably from the DWM tool room, a similar fate of some of the 10000B guns.

The fact that these “1903 experimental” Lugers have 1st and 2nd issue thumb safeties and low 3-digit serial numbers implies that these guns were manufactured in 1901, yet by the patent application date of December 1903 DWM production had reached in excess of 10000 commercial Lugers. This suggests that either these guns were serialized and sat around in the tool room until they were “appropriated” for experimental purposes or they were manufactured circa 1903 and are a separate set of serial numbers. The LOB “1903 experimental” example old model receiver chamber face has the added 6.5 mm extractor cut, a feature not introduced into production until 10000 and beyond. Either this extractor cut was added later, certainly no earlier than 1903 or would err toward a later manufacturing date and a separate serial number range. Also one would expect a 3-digit old model Luger to have an unrelieved magazine feedway and flat follower button magazine of which the LOB example grip is relieved and accepts a domed or stepped follower button magazine.

If one accepts that the LOB example as the apparent production version of the 1903 patent then perhaps there was never a Luger manufactured that completely resembled or demonstrated the 1903 patent intent. Also patent submittals do not necessarily require a working model. In some cases the intent of a patent is to deny the use of the design by the competitors. Luger merely states in his 1903 patent application that, “This known arrangement has heretofore been so carried out in practice….” It is possible that the LOB example is a Luger put together to use up prototype parts, in this case the toggle link assembly since the gun as manufactured does not represent the patent intent in total. Also, it could mean, seeing that two of these GL Lugers exists with the identical toggle link assemblies, that this is as far as the design evolved.

Furthermore it has been suggested that one cannot completely rely on the patent description and drawings. It is feasible that the sole purpose of the surviving examples, which may be more than the two production type examples discussed herein, was an attempt by the designer to minimize muzzle lift by redistributing mass in the toggle link assembly from the rear link to the forward link by making the toggle knobs an integral part of the forward link. By moving the mass more forward tends to neutralize or minimize the raising of the muzzle. This is not discussed at all in the patent application description and infers another patent application, which has never surfaced. Recoil or muzzle lift is mentioned in numerous Luger references such as “Lugers have a recoil of their own; no other gun gives the same sensation, i.e. the bullet has left the barrel before recoil starts. The recoil is felt as a straight push, without any wrist bending or side kick.” 1

Due to the fact that Luger went to great lengths to describe his professed purpose along with detailed figures, this patent suggests that Luger was very serious about his “invention”. Yet it is inferred that this is not the case and that Luger’s intent was subterfuge, i.e. a ploy or ruse, or as Kenyon more subtly states, “a solution seeking a problem” 2. This is unreasonable, as although Luger was considered the ultimate or consummate salesman, he was an innovative engineer first. It is more likely that this patent is an attempt by Luger to document alternative toggle train designs that he tried or contemplated early in the Luger design evolution.

Any chance of an example surviving that totally resembles the patent drawings is extremely remote for the following reason; A Luger so manufactured lacks any safety devices whatsoever to prevent accidental discharge and would be extremely dangerous. This model would never be excessed to the private market and was probably dismantled or destroyed after testing. It is also possible that this design was evaluated on a test jig and not on an actual complete gun.

Facts about the Land of Borchardt and Kenyon "1903 patent" examples:

1 Luger Variations by Harry Jones, Copyright © 1959, p.29.

2 The Gun Report, Vol 50, No.1, June 2004, Lugers at Random column by C. Kenyon, Jr., p13