buttons

"10000B" Series Prototype Lugers "10000B" Series Prototype Lugers

World War 2 German submarine, U-873, surrendered to the USS Vance (DE-387) initially commanded by Lt. Comdr. E. A. Anderson, USCG, on the morning of 11 May 1945, four days after Germany had surrendered. Kapitan-leutnant Fritz Steinhoff was commander of the Nazi submarine U-873. One of the weapons found onboard the German submarine was a 10000 B series prototype Luger. It must have been a private officer's weapon as even at the end of the war, German officers of all services were free to use any personal side-arm they wished. Five days later, on May 16 1945, this Luger was registered in the town of Cohoes, New York by members of the Anderson family with the local Police in accordance with New York state requirements. The registration document amazingly has stayed with this prototype Luger through various owners to the current day. Much has been written about the 10000B series prototype Lugers. This article will introduce new materiel and new prototypes and new theories and will be presented in a manner that integrates existing information with new material in an attempt to expand the knowledge base on this unique, brief, but very active time with Deutsch Waffen und Munitionsfabriken (DWM) in the early development of the Luger. The B series starts with the lowest identified serial number 10023B and ends with the highest known serial number of 10158B. For example, several of the early low digit B series were demonstrations of the various barrel configurations in the development of the 9mm Luger. The later B series were various prototype configurations of the new model Luger. The balance of the B guns are a mix of GL presentation Lugers with such innocuous examples of changes including late old model short frame prototypes to differing grip safety configurations. Rear frame description for the prototype Lugers.The discussion, at this point is restricted to the frame, specifically the rear portion of the frame where the question of a separate series seems to arise. The rear frame thumb safety area typical of all old model production commercial frames up to serial number 25000, the approximate end of old model production, is shown below in Figure 1. Note the ridge contour surrounding the milled out area for the thumb safety. The ridge from the left forward cam ramp area through to the top horizontal surface and down the rear vertical wall exhibit the same width in profile throughout the contour. Also note the outside edge of this contour is rather sharp and angular, i.e. no smooth or rounded edges. Compare this to the 10028B series prototype shown on the right in Figure 1.

The left and right side rear frame ridges surrounding the milled out recesses have been modified. The forward cam ramp lip is thinner in profile. The top horizontal ridge and the rear vertical ridge are of the same width of the commercial example in the same area but give the appearance of being thinner due to the smoothing or rounding of the outside top and rear vertical ridge edges. 10028B is as described and is representative of the configuration of most of the observed 10000B Lugers of what we will now call the Series 1 prototypes, examples being serial numbers 10051B, 10056B and 10070B. Measured from the rear of the frame to the lower forward edge of the cam ramps, these Series 1 B prototypes are 1 mm shorter than the normal old model production guns. This suggests that these gun frames came from the same “batch” and possibly were pulled from the production line at the same time for use in the tool room. The 10130B prototype exhibits the typical commercial or production rear frame configuration. Here is where the argument focuses on the possibility of two series of 10000B prototype Lugers. There are no other physical differences of mechanics or configuration of any of the observed 10000B guns to suggest a different series. Prior to this article there were no identified duplicate or dual serial numbers observed in the prototype 10000B series, only speculation. This article will present photographic proof of duplicate commercial and 10000B series Lugers and one example of a duplicate serialed 10000B Luger. There are a small number of 10000 series guns (10000-10020) with special push button stock lug attachments, which some collectors consider a separate series but here there are no duplicate serial numbers or overlaps noted. Entertaining the possibility of two different prototype series, which for this article we shall call Series 1 and Series 2, begins with the question of the source of the frames If, as suggested by some collectors, that the frames and other components of the 10000B series were pulled from the production line, then the frames in the subject area would have to be modified in the DWM tool room and a separate set of serial numbers set aside. If the 10000B prototype series frames were of completely new manufacture, a separate set of serial numbers would also be needed. The final question is why the minor changes to the rear frames since these changes appear to be cosmetic in nature with no functional implications? The Series 1 prototypes at this point consist of the special rear frame modifications discussed above being found on 10023B, 10028B, 10030B, 10037B, 10046B, 10051B, 10056B, 10060B and 10070B to mention a few. The Series 2 10000B prototype Lugers consists of only 10130B at this stage. The mystery of the two series theory becomes clearer with a fortunate discovery of a Series 1 prototype Luger, 10056B. A review of the current literature for known B series prototype Lugers uncovers another 10056B prototype Luger! This 10000B series prototype Luger is pictured in "Lugers at Random"[1] and is described in the article as fitting a Series 2 prototype. Further information of the 10056B pictured and described by C. Kenyon, Jr. can be found in an article about the Series 2 10056B prototype Luger in an earlier publication called the Luger Journal. The information for the article was provided by the then current owner, J. Pagniano, with photos showing the barrel and frame serial number. ---------------- page 2 --------------- Complete review of Series 1 and Series 2 prototypes.The next step in the puzzle required a comprehensive review of the complete configuration of the Series 1 prototypes, which consisted solely of the 1900 long frame modified Lugers. The 10056B Series 1 prototype was the first pilot example for the late old model 1902 129 mm short frame being modified from a 1900 131 mm long frame Luger/receiver/4-¾” barrel configuration. The features that separate the Series 1 from the Series 2 prototypes are the unique configuration of the Series 1 rear cam ridges coupled with the front frame contour in profile, specifically of the new model prototypes.

The differences are the 10056B Series 1 abrupt 90º blend from the front vertical face to the horizontal blend at the front of the trigger guard vs. the softer, more rounded transition of the 10051B Series 1 prototype. The 10000B Series 2 prototype frames were pulled from the 22000 serial number time frame range production line, being manufactured to the 10056B series 1 pilot prototype front frame contour, referred to as the late old model short frame, except the rear frame cam recess soft outer edges revert back to the standard configuration used throughout production. In summary, all Series 1 prototype frames were modified model 1900 long frames with modified rear cam ridges and all Series 2 prototype frames are standard late old model frames. This is corroborated by the identity of two, a Series 1 and a Series 2 prototype Lugers with the same serial number 10056B.

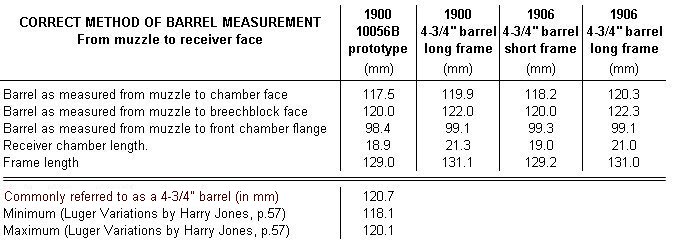

Note the starting point below the take down levers of the reduced width or narrower trigger guards of both Series 1 and Series 2 prototypes shown in Figure 3. The starting point of the step down on 10051B is lower than 10130B and is atypical of the Series 1 new model prototypes whereas 10130B Series 2 prototype represents the final new model production configuration in this area. As to why there are two separate 10000B prototype series requires a time review of manufacture. The Series 1 prototypes were constructed in the 1902-1903 time frame, an example being 10028B and interestingly also a new model 9mm prototype 10069B, part of the Springfield Arsenal collection, mechanically identically configured to 10051B. It has been suggested by a noted expert Luger author [2] that 10069B was demonstrated to the US Army in early 1903 by the designer Georg Luger. If true that a new model 9mm prototype was demonstrated to the U.S. Army in 1903 it is curious that with after testing a new model prototype Luger that the U.S. Army agreed to exchange 50 of the old model Test Eagle Lugers for 50 1904 late old model short frame fat barrel 9mm Cartridge Counter Lugers. Probably more a situation of expediency of both the U.S. Army and DWM as the new model prototype demonstrated was too new and too complicated to produce in a short time frame. Many of these early Series 1 Lugers had various 9mm barrel configurations and were made to promote the new caliber to interested domestic and world customers. The current assumption by some collectors is that an unknown quantity of Lugers were culled from the production line in the 1901-1902 time frame. This first batch of these specially modified Lugers of what would ultimately become Series 1 prototypes were probably used up as commercial production of the standard old model Luger continued. Production output reached in excess of 22000, the late old model short frame Lugers were coming off the production line and there was continued demand for prototype Lugers to demonstrate the development of the new model. The Series 2 new model prototypes came into existence to satisfy that demand. The exception being the late old model 9mm 4” barrel Series 2 duplicate serial number 10056B, which was demonstrating a modified grip safety per the description in “Lugers at Random”. Note that the old model long frame was still in production to fulfill Swiss contract obligations but the logical choice would be the late old model short frame which would involve fewer machining steps. The obvious example of this theory is the Dutch interest in the new model Luger. What appears in history is the Series 2 prototype Luger, S/N 10130B, submitted to the Dutch authorities in late 1905.[3] This theory is promoted and espoused by Charles Kenyon Jr. and is presented in the Springfield Arsenal archives with a description of 10069B. (The Gun Report, August 2000). By this time, the batch of Series 1 prototype Lugers were exhausted and the late old model short frame Luger is in full production. This is the frame that DWM morphed into the new model prototype. Other than the fact that the 10130B new model prototype Dutch Luger frame has been established to have used a late old model production frame to modify into the new model it also differs from the series 1 new model prototypes as it uses a different design rear toggle link which differs from the earlier produced series 1 new model rear link prototypes. The “T” section area behind the 10130B rear link production style 60° hatched square sided toggle knobs sits higher than the receiver and appears identical to the production new model rear link with sharp shoulders, lacking the rounded or softened edges of the 10051B, 10069B and 10070B prototype series 1 new model rear links which have rear links that also sit higher than the receiver rails. This puts the 10130B rear link as the final new model design and interestingly puts the final design rear link, being part of 10130B complete before the frame and the new recoil spring which apparently was not finalized as late as August 1905. This would put the production of 10130B definitely much later than 10051B, 10069B and 10070B. This is a convenient juncture to explore the Dutch claims to be the originators of the new model recoil spring as presented in the 1994 publication of The Dutch Luger book.[4] This theory is promoted and espoused by Charles Kenyon Jr. and is presented in the Springfield Arsenal archives with a description of 10069B. (The Gun Report, August 2000). The Dutch base their claim on two B series prototype Lugers, 10127B and 10130B. 10130B only survives and is featured in the Dutch Luger book and is recorded in the Dutch records as been delivered in August 1905. Based solely on 10130B which has been established to be a series 2 modified late old model production short frame Luger with the final design production rear link installed, obtained from the DWM 22000 serial number production range and modified by DWM to incorporate the new model breechblock extractor combination and the new recoil mainspring. The configuration of 10130B series 2 is essentially identical, in prototype features except using a late old model production frame and final production design rear link, to 10069B series 1 prototype Luger submitted to the US Army but with 10069B featuring a LOADED marked extractor, in 1903 and 10070B which is featured and described in the Dutch Luger book as “A very interesting pistol which might have served as a prototype for the Dutch modifications……” Interestingly 10070B sports a narrow eared extractor but also with a hand stamped LOADED extractor, not GELADEN[5]. A lesser known new model B series GL prototype new model Luger but recognized and authenticated by Luger authorities[6] is 10051B. This Luger is of series 1 prototype as is 10069B and 10070B and is clearly one of the very first new model prototypes being modified from a 1900 old model long frame obtained from the 10000 serial number commercial production range. There is no doubt of 10051B being manufactured and modified several months or possibly a year prior to 10127B and 10130B series 2 prototypes. With that stated, 10051B with its new model recoil spring and breechblock is clearly Teutonic in its markings, sporting a hand stamped GELADEN marked, narrow eared extractor and GEISCHERT marked thumb safety recess making a strong case or argument for the Germans being the inventors of the new model mainspring. ---------------- page 3 --------------- Description of 10056B prototype Luger.The condition of the 10056B prototype is unusual, as it appears to have some shellac type of coating on all of the metal parts and when first acquired the grips were coated in the same manner. The wooden grips looked like they were coated in resin. A solvent was used to remove the coating from the grips and they are very worn but are original to the gun. The last two digits of the S/N are stamped on the inside grip surfaces along with inspection marks. The underlying surface of the gun retains about 85% of its original finish except for the better condition of the shielded areas and the interior parts. The barrel finish is mostly intact and the barrel is stamped with the full serial number 10056. All the small parts that would be normally strawed are black. This gun has significant wear and appears to have been refinished at some point in time, although the interior surfaces of the gun are original metal, albeit a lot of dark patina. 10056B is different from the 1905 new model prototype 10051B in the area of markings. 10056B seems to have come off the production line with inspection stamps and other numbers stamped in various places that 10051B lacks; a flaming bomb type inspection mark in the forward lug well and a small number 4 stamped in the breechblock extractor recess. The bottom of the flat extractor has a shield type inspection stamp. The right side edge of the take-down lever is stamped with the number 3. The sear bar, trigger, take down side plate, grip safety, the breechblock, middle and rear link are stamped with the last two digits of the serial number. The take-down lever, magazine release and the thumb safety are not stamped. The grip safety is stamped on the inside surface. It is not known if there is any significance for a B gun with or without the various oddball factory marks other than the serial numbers. There are early old model production Lugers with no marks or stamps other than the serial numbers. The pistol was manufactured and “appropriated” by the DWM tool room completely assembled as an old model long frame Luger with an old model 30 cal 4-3/4” barrel and stamped 10056. The barrel was removed from the receiver and the receiver was shortened 2mm from 21mm to 19mm to correspond to the frame, which was also shortened 2mm from 131 mm to 129 mm and the entire front frame was reshaped or machined from the long frame contour to the more abrupt shortened contour of what would be referred to by collectors as the late old model short frame Luger. The frame was then restamped with the 10056 serial number with the added letter “B” stamped under the serial number indicating its prototype status. The modification required of the original barrel to be refitted to the shortened receiver was unique and was determined mathematically and is described below. The frame modification is the pilot model for and is identical to the 22000-23000 series late old model short frames with the exception of the full width trigger guard edges of 10056B being slightly rounded or softened. Model 1900 long frame conversion of 10056 commercial Luger to short frame/receiver 10056B configuration using the original 30 cal modified 4-¾” barrel.Prototype 10056B used the 1900 old model long frame and production barrel as evidenced by the identical font style and size of the frame and barrel serial number which is similar to surviving typical five digit serial numbered old model 1900 commercial Lugers and 1902 late old model commercial Luger serial numbers. Guns with true prototype barrels in the 10000B series, such as serial number 10023B with a 9 mm, 6 inch "fat" barrel, serial number 10028B with a 9 mm, 4-3/4 inch "fat" barrel and serial number 10051B with an experimental new model production style 9mm barrel, the style and size of the barrel serial number is different and much smaller than the frame serial numbers. This is what one would expect in a new barrel. However, the font style and size of the 10056B barrel serial number is identical to the frame serial number since the barrel was mated with the gun during original assembly. 10056B prototype Luger is a short frame/receiver/barrel modified from a model 1900 131 mm long frame old model Luger, originally manufactured with a 4-¾” barrel and was the demonstration or pilot model for the late old model production 129 mm short frame Luger . The modification was accomplished by removing 2.0 mm from the front of the frame, 2 mm from the front of the receiver and approximately 2 mm from the barrel face. A standard late old model 129 mm short frame or new model production 129 mm short frame Luger with a 4-¾” barrel installed will measure 118 mm as measured from the muzzle to the chamber face. It has been conjectured by some collectors that in production, the threading of the barrel and receiver were carefully jigged to start the threads at the same place every time, to minimize the hand fitting necessary to get the headspace and foresight bed alignment within tolerance together when the barrel was torqued down into the receiver. The only adjustment available after the components were threaded was to either cut back the receiver (which would produce a mis-alignment to the front of the frame) or to cut back the barrel flange (shoulder) to allow it to sit deeper into the receiver. As noted before, simply cutting 2 mm of the back of a production long frame barrel would have left the barrel overall length at 118 mm, not the required 120 mm long, as well as requiring re-chambering. The first part of this argument is quite accurate regarding the initial description of the production installation but misleading regarding the 120 mm barrel length requirement. 10056B was so modified as described below while restoring the proper headspace even though the total barrel length was shortened by approximately 0.5 mm. The following table of barrel and receiver measurements also demonstrates the 0.5 mm difference.

From the original new model Luger blueprint, the thread pitch gives 1.27 mm per 360° rotation of the barrel. When reinstalling the barrel in the 2mm shortened receiver, the misalignment of the original witness marks on the bottom of the barrel flange with the receiver witness mark was off by 155°. To properly seat and realign the barrel and receiver, the barrel was removed and approximately 0.5 mm removed from the barrel flange. The barrel was reinstalled and aligned to the original existing receiver witness marks. This is corroborated by measuring the barrel length of 10056B barrel from the muzzle to the chamber face which measures 117.5 mm or 0.5 mm shorter than the standard production short frame 4-¾” barrel Luger. As a result of machining 2 mm off the barrel face, the barrel chamber required reboring to reestablish the proper headspace . The barrel extractor slot and the cartridge feed ramp in the lower barrel face had to be remachined into the barrel face as well. Since production jigs were in place for the old model 4-¾” barrel the task was relatively simple. 10060B, a recently discovered Series 1 prototype Luger being identically configured as 10056B, was reworked in the same manner. The 4-¾” barrel of 10060B is the factory original as is 10056B, albeit both barrels being modified. It wasn’t until the 22000 range of production when the short frame was introduced and jigs put in place that would properly key the thread starts in the receiver and the new barrel so that proper alignment was accomplished. The barrel shoulder reverted to the old model production shoulder dimension of 1.5 mm resulting in a barrel length as measured from the muzzle to the chamber face of 118 mm. It should be noted, for clarity, that the barrel length of 10056B and a standard production short frame as measured from the muzzle to the breechblock face both measure 120 mm. This shows that there was no requirement for the barrel to be 120 mm long as quoted above. The long frame 4-¾” barrel Lugers, old and new model measure 120 mm from the muzzle to the receiver face and 122 mm from the muzzle face to the breechblock face. The final difference is the sight blade, which in profile is different from the standard old model 4-¾” 30 cal barrel sight blade. The rear edge is serrated with a straight slope contour vs. the stepped non serrated rear edge. The 10000B prototype 9mm guns also have this type of sight blade. The only 4-¾” 30 cal barrel observed with the identical sight blade as 10056B and 10060B is the Model 1900 with simplified safety mechanism in the 9900 commercial range[7]. It is interesting to note that the serrated rear edge slope sight blade was adapted for the new model 9 mm Lugers yet reverted to the original old model 4-3/4” 30 cal barrel sight blades for the new model 4-¾” 30 cal barrels. The general consensus is that the prototype 10000B guns with GL logos were presentation guns and the non GL marked 10000B prototype Lugers were for military/test purposes. Additionally, old model Lugers with the new type serrated front sight blade were specifically for military test. Externally viewed that would be the extent of the modifications to the prototype 10056B luger. The toggle train is standard old model and there are not any other external modifications. ---------------- page 4 --------------- Chamber face extractor cuts.A 6.5 mm wide cut was added to the receiver chamber face of 10056B above the existing old model style 5.5 mm wide barrel extractor cut, which is first seen and incorporated in the 10000B series with 10056B being the first 4-3/4" 30 cal barrel seen with the cut. The added cut was incorporated to eliminate a problem encountered when feeding a single round into the chamber from the top. When inserting a round in the manner described and releasing the toggle link assembly to full battery tended to raise the extractor too high for the extractor claw to engage the cartridge case lip. This caused the angled tip of the extractor to hit the top of the chamber face thereby damaging the extractor, the chamber face or both. This condition does not exist normally when the round is chambered from below, stripped off the magazine, as the extractor claw does not have to rise as much to engage the cartridge lip or rim. As to what B gun gets the credit for having the first modified receiver face extractor cut is not known but the cut is first seen in the B series. It would seem to have been incorporated at least by 10028B 9mm prototype Luger as it has the 6.5 mm wide added receiver extractor cut as compared to an old model luger without the added receiver extractor cut. The first commercial production Luger noted with the added receiver face extractor cut is serial number 10285 AE. There are no guns below commercial serial number 10000 observed by the author with the added 6.5 mm wide receiver extractor cut. Possibly all of the old model B-suffix receivers have the added extractor cuts and are evident even in the 10000B 9mm new model prototypes, 1904 transitional navy Lugers and the 25000-25050 French Chargé Lugers which will be discussed later in this article. The new model breechblock extractor and chamber cut for the extractor protruding tip and claw was designed to eliminate the condition encountered in the old model. The relief bevels on the inner underside corners of the 10056B receiver rails have been deepened to a 45° angle from the standard shallow 18° bevel of the 1900 old model luger, similar to 10060B and 10070B. The exception of the bevels in the 10056B receiver rails being the abrupt termination of the bevel at the lower chamber face with virtually no flat. All new model production Lugers incorporated the addition of the bevels on the underside of the receiver rails and some 22000-23000 serial number late old model carbines have been observed with the modification. The last Swiss contract series of old model Lugers which were delivered in 1906 (4269-5000) have the new receiver underside rail bevel cut. The 45° receiver rail underside bevel seems to have started between the 1902 30 cal Danzig arsenal proofed German army test Luger, serial number 22350, and the 1902 9mm Cartridge Counter Luger, serial number 22414. Luger S/N 22350 has the original shallow receiver rail underside cut and S/N 22414 has the new receiver rail underside cut. The reason for the addition of the bevel to the underside of receiver rail was possibly related to a problem with the magazine. The top of the sheet metal magazine body curved lip had a tendency to deform, flare or “bulge”, after a certain amount of feed cycling. The bevel was added to allow for more clearance between the top left and right sides of the magazine body curved lip and the receiver rail undersides to minimize the possibility of binding during recoil or receiver cycling. The weight savings gained with the material removal, of both receiver rails for the bevel change was a miniscule 2.3 grams. The forward surface of the 10056B receiver stop lug has been softened or rounded, perhaps there was an interference problem. The firing pin tip of 10056B is 1 mm longer than the typical production firing pin tip. The firing pin spring is also longer than the production spring; 54 mm in length with a coil diameter of 0.75 mm and 20 coils versus 47 mm in length with a coil diameter of 0.75 mm and 17 coils for a production spring. This could be a later modification, although there is archival evidence of longer firing pins being used during the first March 1901 US Army Luger test program of the Model 1900 30 Cal Luger where Hans Tauscher the DWM local representative requested the "...substitution of a longer firing pin, in order to prevent future misfires, and repeat the test. This was agreed by the board." [8] The recoil spring in the Series 1 10056B is a single leaf tapered flat recoil spring. The spring is a little longer than a standard spring, which makes it sit higher in the frame. The taper is thickest at the lower end and the transition from the top of the hook to the bottom is very smooth and gradual from 1.2 mm at the top, 1.3 mm in the middle to 2.3 mm at the bottom. The spring at the top shows color or evidence of temper. At the bottom of the spring is a machined lip versus the bent lip of the original spring which is used to anchor the spring in the recess of the lower frame. The spring required complex machining due to its constant varying taper. Since 10056B is a prototype gun, the single piece flat roband spring could be an experimental spring. However, in light of the recoil systems in 10051B and 10070B, it does not seem plausible. This gun could have had an original riveted, dual leaf spring that was replaced later by an enterprising mechanic. Although from a wear and condition point of view, the single leaf spring seems contemporaneous to the gun. The breechblock and the left side of the receiver of 10056B are stamped with the lazy crown N commercial proof. Apparently sometime in the life of 10056B it was released by DWM for commercial sale. The lazy crown N proof doesn’t appear on guns until about serial numbers 49000 and later, circa 1910. If 10056B was modified in 1902, that’s eight years the gun was in limbo. The only place it could be was in the DWM tool room. The location of a few of the B guns are known today, but DWM’s policy on B guns after they served their purpose is unknown. The theory is that production guns were modified to demonstrate some feature, major or minor, prior to being serialized and then new serial numbers and a B suffix were applied. In the case of 10056B the feature seems to be the shortened frame/receiver, which is more than likely the pilot for the late old model short frame. The fact that it comes after 10051B, which obviously was modified to demonstrate the new model, is another example of the non-sequential nature of the 10000 series B guns. This business with the seemingly “after thought” process and inconsistent variety of receiver chamber face extractor cuts with the 1903 French Chargé Luger, the 1904 transitional navies and the “new model” B guns is peculiar, especially since the patented 1904 new model with the perfected final design, except for the narrow eared extractor, the breechblock was a reality at the time of these guns. Luger apparently did not consider the corresponding required receiver extractor cut requirements at the time of the patent of the new type extractor. Probably because the patent for the new type extractor used a rifle as an example, not a pistol, yet was adapted to the Luger. The Luger and the patent drawings intent was to show or emphasize the new style extractor and not the corresponding receiver face and was not specific in this regard. This nuance was not addressed until the finalized production drawings for the new model Luger. By 1904 the 6.5 mm wide added extractor relief cut was a production “fate accompli” in both the old model and late old model receiver faces. The 10051B new model prototype receiver face extractor cut which at first glance appears to be a new model style extractor cut is in fact what’s left of the old model receiver face 6.5 mm wide added extractor relief cut and bevel. The 6.5 mm wide added receiver cut extends on each side of the 4.2 mm wide rectangular cut in the top of the chamber face for the new model extractor protruding tip. The added cut on each side of the receiver face extractor tip recess is too wide and beveled to be the final production version of which is a 0.5 mm wide angular cut. There is another observed 2 digit 1904 Transitional Navy Luger , serial number 36, with receiver chamber cuts that more closely resembles the final production version. Since it has been established that all the 1904 Transitional Navy Lugers were assembled with modified old model long frame receivers, the similarity of the receiver face to the final production is attributed to the fact than an old model long frame receiver was used that didn’t have the added 6.5 mm wide added receiver extractor relief cut. Whether the choice of old model receivers used was selective or random is not known at this time although it as been determined by observation that the added 6.5mm wide receiver cut was incorporated in production sporadically in the 10000-12000 commercial serial number range and on a continual basis after 12000 and continued throughout old model production. Note also the variation in the extractor cuts of the 1904 Transitional Navy Luger serial number 79 receiver face chamber cut and the 1904 Transitional Navy Luger serial number 136 receiver face chamber cut of which both have the added 6.5 mm wide receiver chamber face cut. The 10051B new model prototype receiver face is similar to or more closely resembles an observed, but not shown 1903 production, transitional late old model French Chargé Luger in the 250xx commercial serial number range, which the late old model receiver chamber face with the added 6.5 mm beveled receiver extractor relief cut, was modified to accommodate the interim new model breechblock and protruding extractor tip. Based on the above descriptions every transitional 1903 French Chargé Luger, 1904 Transitional Navy Luger and every new model prototype B series Luger has to be examined in this area on a case-by-case basis for authenticity, which is only a single area and cannot be used alone to verify authenticity as it is only one of many unique machining characteristics and configurations of this transitional group, too numerous to be described for this article and additionally even then, it is very difficult to get a consensus of opinion even from the professionals. What is learned from this examination is that all the 10000B series prototype Lugers using the new model design breechblock were fabricated with old model receivers with interim hand cut receiver chamber face extractor cuts. As mentioned above, there is no doubt that all “correct” 1904 Navy Transitional Lugers and new model 10000B prototypes used old model receivers. The use of old model receivers also includes, besides all the 1904 Transitional Navy Lugers also the “1903” French Chargé Lugers. The receiver chamber face extractor cut was not finalized until new model production, after the introduction of the “1904” patented new model breechblock and GELADEN marked extractor. The final new model design for the chamber face extractor cut featured a completely vertical receiver chamber face wall with a precise extractor cut which included small 0.5 mm wide angled cuts in the chamber wall on each side of the extractor cut to accommodate or allow the breechblock extractor to rise in certain conditions higher than normal when engaging the cartridge lip. The chamber top was also changed from a circular design to a flattened or elliptical surface to allow for more visibility of the new extractor in profile when loaded. It is certain, even with the minimum information presented herein that there is no chronological order or evolution of design changes in the 10000B series prototype Lugers, especially in the receiver chamber extractor cuts. It is also certain that the 1904 Transitional Navy Lugers with their own set of serial numbers were not necessarily produced sequentially for the same reasons cited for the B guns, namely the random nature of the receiver chamber extractor cuts. There are 31 reported examples of the B gun prototypes known to the author as identified by various sources. Pictures of nineteen of the guns frame serial numbers are listed here: 10023B, 10028B, 10029B, 10030B, 10031B, 10046B, 10051B, 10056B, 10060B, 10066B, 10067B, 10070B, 10075B, 10078B, 10087B, 10088B, 10130B, 10161B, 55067B and 55076B. Two of the guns listed have duplicate commercial serial numbers. The first is 10078 of which only the frame survives and the second is 10088 which is identified in the Dutch Luger Book as 1 of 10 “Trials Model 1904” delivered in December 1903. [9]

AsideThe following is C. Kenyon’s response to a question about the introduction and reasons for the short frame/receiver. No proven answer of factory source nature, but I’ll venture a likely scenario. The “short” frame/receiver was introduced at about serial 22000 in the “old model” production and would appear to have been incorporated to make the weapon a little lighter and more compact in the 100 m/m barrel configuration appearing at about the same point. This would have been at approximately mid-1903. By mid-1905 it would appear that the “new model” Luger was about to be introduced and the “short” receiver length was in play. Recall that at this point D.W.M. had only two secured military contracts, the Swiss and the German navy (just being solidified). I would think that the Swiss would be very negative toward obtaining additional Lugers with the barrels not conforming to those previously accepted (the 1900 Swiss models). It could well be that rather than face the possibility of renegotiation, additional trials or customer resistance, the “long” receiver was kept in the product line. ---------------- page 5 --------------- Genealogy of 10056B Series 1 prototype LugerAs mentioned in the beginning of this article, a document pertaining to the history and origins of Luger prototype serial number 10056B was obtained with the gun. The document is the top third portion of an 8-1/2” x 11” format paper. The letter was originally folded, probably because it was carried in a wallet for identification and years later unfolded and laminated to preserve it. The World War 2 German submarine mentioned in the above letter was found to be U-873 and the Anderson mentioned in the document was the same Anderson involved with the capture of U-873 of which the time frame coincides exactly with the time frame of the May 16, 1945 “capture or registration” letter. The following is some background material and documentation presented as found:

It has been pointed out by another well known Luger collector that if 10056B was on a U Boat in 1945, it must have been a private officer's weapon - even at the end of the war, officers of all services were free to use any personal side-arm they wished, and there is plenty of photographic evidence of this, with officers using non-issue weapons in all sorts of circumstances. What would be really interesting, but is now lost in time, is how the officer in question came into possession of the pistol - almost certainly it was sold off by DWM in a tool-room clear-out ca. 1912-13, and either came down through the officer's family or second hand through a dealer. Since it is a non military standard caliber, my conclusion would be on the first, and that it was handed down from his father as an heirloom, quite possibly having seen service in WWI also if it was a military/naval family or the first, and that it was handed down from his father as an heirloom, quite possibly having seen service in WWI also if it was a military/naval family. All three of these prototype Luger B guns (10051B, 10056B, 10070B) share the same rear frame finishing characteristics and were probably obtained from a specific production run batch and modified by the same technician.

|

Home page

Home page